Natural Graphite Electrode - UHP Grade Graphite Electrode with Nipples for Ladle Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Graphite Electrode Description

Topfly Material has complete production lines, which include raw material mixing, forming line, baking line, impregnation equipment, graphitization line and machining and shaping line.

Graphite electrodes, widely used in steelmaking, non ferrous, silicon industry. According to their level of quality, it can be divided into RP, HP and UHP grade. This item is for UHP grade graphite electrode. Resistivity: ≤5.5ohm, Bulk Density: ≥1.68g/cm3. Diameter is 350-700mm, length is 1800±100mm.

2.Main Features of the Graphite Electrode

(1) High quality and carbon content.

(2) Competitive price, we have price advantage for UHP.

(3) High density ≥1.68g/cm3 and low resistivity≤5.5ohm

(4) Large quantity in stock, you can order directly.

3.Graphite Electrode Images

More products for your reference:

Packaging: Wooden Pallets

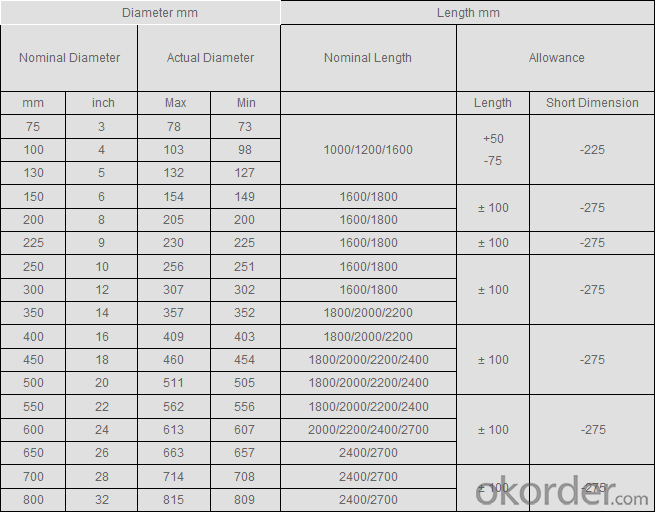

4.Graphite Electrode Specification

5.FAQ

We have organized several common questions for our clients, may help you sincerely:

(1) How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; we resolutely put an end to unqualified products material flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(2) MOQ

For trial order, we accept 5 MT.

(3) Payment term

30% deposit, balance against the BL copy; 100% L/C at sight.

(4) How long can we receive the product after purchase?

We have large quantity in stock, and we could machine it to the size you need, so the delivery time is around 25 days after receiving your deposit or L/C.

- Q: Is graphite electrode good for foreign trade?

- Foreign sales commission depends on the price you talk to the customer, and the profit is objective.

- Q: Why should the carbon brush for the trolley be made of graphite?

- Graphite has good conductivity

- Q: Is graphite flammable?Why do I bake pencil cores with a fever that doesn't burn?

- The temperature is not enough, the composition of graphite is carbon, of course, flammable, but each kind of object burning point is not the same, the nature of graphite is relatively stable, burning point is very high, cigarette lighter this temperature is certainly not burning up.Useful words, remember to adopt Oh, thank you ~!

- Q: What is the role of the Pt electrode? What is the difference between the graphite electrode and the graphite electrode?

- In the electrochemical process, the electrode should not affect the reaction on the working electrode, so platinum and graphite are often chosen

- Q: Graphite powder produced by graphite electrode and what we usually call graphite is a kind of thing?

- Coal tar pitch as binder is made by calcination, batching, kneading, pressing, roasting, graphitization and machining

- Q: What's the purpose of the electrode material?When the electrolytic molten state of NaCl is said, what is the use of the graphite electrode and the iron electrode?

- 1. graphite (two kinds of EDM3 and EDM200)2. copperIn general, graphite electrode for extensive escape material (graphite texture loose, discharge energy is relatively large, removal of materials faster, but face flowers that roughness is relatively large

- Q: Why is the production of one ton of ultra high power graphite electrode requires 1.05 tons of coke?

- After calcined to eliminate ash and volatile part of the points in this process will be a lot of weight loss, in the process of crushing mixing in process of baking or graphite in high temperature heat treatment, another part of the impurities were excluded, so the raw material is higher than the rate of finished products.

- Q: Iron and graphite as electrodes and Nacl as electrolyte solutions. Why do they produce electric current? Graphite and iron react not with solution, can they be connected by wires?

- Because the metal activity order form sodium potassium calcium magnesium aluminum, zinc and tin lead (hydrogen), mercury copper silver platinum, iron in the front row because of water water hydrogen, ionized hydrogen ions by iron replacement

- Q: 800KVA and 12500 EAF transformer data graphite electrode furnace.

- Graphite project: Project Description: steel furnace and iron smelting furnace, ferrosilicon smelting, electrolytic aluminum and so on, all use large surface graphite electrode.

- Q: What is the difference between SGL graphite electrode and graphite electrode in general?

- In fact, the graphite electrode abroad (including Japan) in several ways than we can control the fine, one is pure, another is anisotropic (resistance, thermal conductivity ah) usually do some control, in the strength of domestic now is also doing well, but when we are comparing high quality products, general domestic products it is basically a piece of the indicators are poor

Send your message to us

Natural Graphite Electrode - UHP Grade Graphite Electrode with Nipples for Ladle Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches