Chemical Index of Graphite Electrodes UHP with Nipples

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Chemical Index of Graphite Electrodes UHP with Nipples

1.Diameter: 200 to 700mm

2.Length: 1600 to 2400mm

3.Nipple:3-4TPI

Chemical Index of Graphite Electrodes UHP with Nipples

1. Grade: RP, HP, UHP, SHP, RPI

2. Diameter: 200 to 700mm at your choice.

3. Length: 1600 to 2400mm at your choice.

4. Nipple: 3-4 TPI

5. Fine mechanical strength and machining quality, low specific resistance, high temperature and oxidation resistance

6. Low price and timely delivery.

Feature

Chemical Index of Graphite Electrodes UHP with Nipples

Grades: RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

UHP

Physical and chemical index

Item | Unit | Nominal Diameter(mm) | |||

YB/T4088-2000 | Typical Values | ||||

Industry Standard | |||||

300-400 | 450-550 | 350-550 | |||

Resistance | Electrode | ohm | ≤6.2 | ≤6.5 | 4.6-6.2 |

Nipple | ≤5.5 | ≤5.5 | 3.5-4.5 | ||

Bending Strength | Electrode | Mpa | ≥10.5 | ≥10.0 | ≥11.0 |

Nipple | ≥16.0 | ≥16.0 | ≥18.0 | ||

Elastic Modulus | Electrode | Gpa | ≤14.0 | ≤14.0 | ≤13.0 |

Nipple | ≤18.0 | ≤18.0 | ≤17.0 | ||

Density | Electrode | g/cm3 | ≥1.65 | ≥1.64 | 1.65-1.72 |

Nipple | ≥1.72 | ≥1.70 | 1.75-1.82 | ||

Ash content | Electrode | % | ≤0.3 | ≤0.3 | ≤0.3 |

Nipple | |||||

CTE(100-600) | Electrode | 10-6/C | ≤1.5 | ≤1.5 | 1.20-1.40 |

Nipple | ≤1.4 | ≤1.4 | 1.10-1.30 | ||

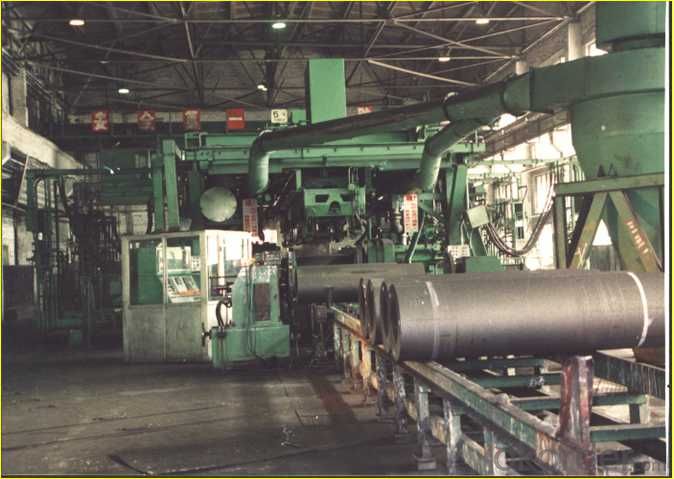

Image

Chemical Index of Graphite Electrodes UHP with Nipples

FAQ:

Chemical Index of Graphite Electrodes UHP with Nipples

1. Why it is essential to select electrode carefully for each particular furnace?

The primary factor is the maximum current intensity of the furnace. However, other conditions should also be considered, such as the characteristics of the furnace, type of charge, tap to tap time, oxygen blowing, mechanical requirement, furnace regulation, etc.Generally, specifications for electrodes of most grades have been standardized. Variation of physical characteristics with temperature, however, should be taken into account whenever using the electrodes.

Precautions to the use of graphite electrodes

2. Why it is essential to not to fit electrodes and nipples made by different manufacturers together?

The capacities of the furnace and the transformer determine whether the grade and diameter of the electrode are suitable to the furnace or not.

In order to prevent the electrode column from being hit by the collapsed furnace loads, large and heavy scraps should be loaded onto the bottom of the furnace. Do not put significant quantity of insulating materials such as lime and so on just under the electrode column, otherwise it would be difficult to power on the electrode column, or even break it.

electrode column may be hurt when it moves up and down if the furnace cover is out of the position.

When making a connection, lost or damaged pitch plugs must be replaced.

The reason must be found out if a gap appears between two electrodes after connection. The electrode column can only be loaded after the gap being eliminated.

The electrode column must be strictly perpendicular to the ground lever. Oblique column is not allowed during operation.

The holder must be placed between the two safety marks on the top electrode, otherwise the column may be broken.

Generally, different manufacturers may make their electrodes with different raw materials and processes, therefore the physical and chemical properties of their electrodes are usually different. Please do not fit electrodes and nipples made by different manufacturers together.

Applications

Chemical Index of Graphite Electrodes UHP with Nipples

Electrodes in electric arc furnace and ladle refining furnace for steel making;

Electrodes in electric smelting furnace for producing industrial silicon, yellow phosphorus, corundum and so on.

- Q: Why graphite can be used as conductive material?

- Lubricants can not be used in high speed, high temperature, high pressure conditions, and graphite wear-resistant materials can be at the temperature and at a high sliding speed, without lubricating oil work. Many transporting corrosive media devices are widely used, which is made of graphite material piston ring, the sealing ring and the bearing, they are running, without adding lubricating oil, graphite and many metal processing when good lubricant.

- Q: The use of graphite as an electrode in alumina electrolysis

- Graphite acts as an electrode:The electrical conductivity of graphite, the electrode itself must be electrically conductive;When graphite acts as an anode, it acts as a reducing agent and displaces an element of aluminum in a chemical reaction;Graphite is cheap and cost saving.

- Q: What kind of asphalt is better for natural graphite coating?

- Main types of graphite electrode with petroleum coke and needle coke, coal tar pitch as binder, calcination, mixing, kneading, pressing, baking and graphitization, and made the processing machine, is a conductor in an electric arc furnace to form arc release electricity for heating and melting of the charge, according to the quality index level, can is divided into ordinary power, high power and ultra high power.

- Q: Can graphite be used as an electrode for electrolysis of silver in silver nitrate?

- Xiaoyi Liyang said the principle is correct, but can get silver? I think we can solve the problem if we take proper measures to get the silver elements, such as separating the anode and the cathode from the salt water!

- Q: MITSUBISHI machine graphite electrode processing, how does not accumulate carbon?

- The three is difficult cold start, is sparking difficult, not easy car, and finally the combustion chamber carbon Yan will cause a heavy cylinder knock, low speed and acceleration noise, causing damage to the piston and crankshaft, causing the engine temperature which can seriously affect the automobile safety. Emission standards exceeded, not only through the annual inspection, but also directly aggravate the pollution of the environment

- Q: What's the purpose of the electrode material?When the electrolytic molten state of NaCl is said, what is the use of the graphite electrode and the iron electrode?

- 1. graphite (two kinds of EDM3 and EDM200)2. copperIn general, graphite electrode for extensive escape material (graphite texture loose, discharge energy is relatively large, removal of materials faster, but face flowers that roughness is relatively large

- Q: How much does a graphite electrode cost about a ton?

- Electrode is divided into ordinary power motor, high power electrode, ultra high power electrode, the gap between the price is still relatively large

- Q: What are the factors that affect the electrode wear rate of machine tools?

- Influence of pulse interval on electrode wear. When the pulse interval is large, the electrode loss increases, which is due to the deterioration of the thermal effect condition and the damage of the "covering effect".

- Q: Graphitized coke, graphite, broken, mixed up, how to export?

- The graphite powder is soft, black and gray, greasy and polluting paper. Hardness is 1~2, along the vertical direction with the increase of impurities, its hardness can be increased to 3~5. The specific gravity is 1.9 ~ 2.3. Under isolated oxygen conditions, the melting point is above 3000 degrees Celsius and is one of the most refractory minerals. At room temperature, the chemical properties of stone toner are relatively stable, insoluble in water, dilute acid, dilute alkali and organic solvents. The material has high temperature resistance and conductivity, and can be used as refractory materials, conductive materials, wear-resistant and lubricating materials.

- Q: Jiqiu conductive graphite electrode, how to compare with copper is relatively large resistance value?

- This is not a good estimate of the sheet graphite resistance after 5mm

Send your message to us

Chemical Index of Graphite Electrodes UHP with Nipples

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords