Graphite Electrodes Price - UHP with Nipples for Steel Plant

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Chemical Index of Graphite Electrodes UHP with Nipples

1.Diameter: 200 to 700mm

2.Length: 1600 to 2400mm

3.Nipple:3-4TPI

Chemical Index of Graphite Electrodes UHP with Nipples

1. Grade: RP, HP, UHP, SHP, RPI

2. Diameter: 200 to 700mm at your choice.

3. Length: 1600 to 2400mm at your choice.

4. Nipple: 3-4 TPI

5. Fine mechanical strength and machining quality, low specific resistance, high temperature and oxidation resistance

6. Low price and timely delivery.

Feature

Chemical Index of Graphite Electrodes UHP with Nipples

Grades: RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

UHP

Physical and chemical index

Item | Unit | Nominal Diameter(mm) | |||

YB/T4088-2000 | Typical Values | ||||

Industry Standard | |||||

300-400 | 450-550 | 350-550 | |||

Resistance | Electrode | ohm | ≤6.2 | ≤6.5 | 4.6-6.2 |

Nipple | ≤5.5 | ≤5.5 | 3.5-4.5 | ||

Bending Strength | Electrode | Mpa | ≥10.5 | ≥10.0 | ≥11.0 |

Nipple | ≥16.0 | ≥16.0 | ≥18.0 | ||

Elastic Modulus | Electrode | Gpa | ≤14.0 | ≤14.0 | ≤13.0 |

Nipple | ≤18.0 | ≤18.0 | ≤17.0 | ||

Density | Electrode | g/cm3 | ≥1.65 | ≥1.64 | 1.65-1.72 |

Nipple | ≥1.72 | ≥1.70 | 1.75-1.82 | ||

Ash content | Electrode | % | ≤0.3 | ≤0.3 | ≤0.3 |

Nipple | |||||

CTE(100-600) | Electrode | 10-6/C | ≤1.5 | ≤1.5 | 1.20-1.40 |

Nipple | ≤1.4 | ≤1.4 | 1.10-1.30 | ||

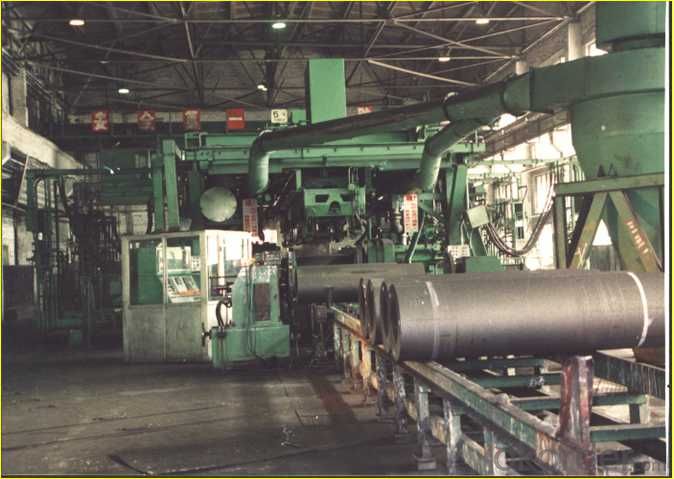

Image

Chemical Index of Graphite Electrodes UHP with Nipples

FAQ:

Chemical Index of Graphite Electrodes UHP with Nipples

1. Why it is essential to select electrode carefully for each particular furnace?

The primary factor is the maximum current intensity of the furnace. However, other conditions should also be considered, such as the characteristics of the furnace, type of charge, tap to tap time, oxygen blowing, mechanical requirement, furnace regulation, etc.Generally, specifications for electrodes of most grades have been standardized. Variation of physical characteristics with temperature, however, should be taken into account whenever using the electrodes.

Precautions to the use of graphite electrodes

2. Why it is essential to not to fit electrodes and nipples made by different manufacturers together?

The capacities of the furnace and the transformer determine whether the grade and diameter of the electrode are suitable to the furnace or not.

In order to prevent the electrode column from being hit by the collapsed furnace loads, large and heavy scraps should be loaded onto the bottom of the furnace. Do not put significant quantity of insulating materials such as lime and so on just under the electrode column, otherwise it would be difficult to power on the electrode column, or even break it.

electrode column may be hurt when it moves up and down if the furnace cover is out of the position.

When making a connection, lost or damaged pitch plugs must be replaced.

The reason must be found out if a gap appears between two electrodes after connection. The electrode column can only be loaded after the gap being eliminated.

The electrode column must be strictly perpendicular to the ground lever. Oblique column is not allowed during operation.

The holder must be placed between the two safety marks on the top electrode, otherwise the column may be broken.

Generally, different manufacturers may make their electrodes with different raw materials and processes, therefore the physical and chemical properties of their electrodes are usually different. Please do not fit electrodes and nipples made by different manufacturers together.

Applications

Chemical Index of Graphite Electrodes UHP with Nipples

Electrodes in electric arc furnace and ladle refining furnace for steel making;

Electrodes in electric smelting furnace for producing industrial silicon, yellow phosphorus, corundum and so on.

- Q: Electrolytic salt water why use iron as a cathode, all with graphite can not?

- When electrolyzed salt water is used, the cations in the solution (H+, ionized by H2O) are moved to the cathode by the electric field force, and electrons are generated at the cathode to produce H2 hydrogen, and the hydrogen H2 generated does not react with iron

- Q: What are the structures of pyrolytic graphite electrodes? What are their properties and applications? We hope that some details will not be found

- The graphite part is called pyrolytic graphite. Stronger than ordinary graphite, strong oxidation resistance.

- Q: Which department in the steel plant needs graphite in large quantities?

- For steel and iron alloys, graphite electrodes are used, when powerful currents pass through electrodes into the melting zone of the electric furnace to produce an arcThe electric energy is converted into heat energy, and the temperature is increased to about 2000 degrees, so as to achieve the purpose of smelting or reaction. In addition, the electrolytic goldWhen the magnesium, aluminium and sodium are used, the anode of the electrolytic cell is also made of graphite electrode. The resistance furnace for carborundum is also made of graphite electrode as the burnerConductive material.

- Q: What is the application of wire cutting with graphite electrode?

- With the development of science and technology, the machine manufacturing technology has undergone profound changes. Due to the social demand for diversification of products is more intense, more varieties, small batch production increasing proportion in WEDM by traditional processing equipment has been difficult to adapt to the processing of high efficiency, high quality, diversified requirements, CNC technology should be used

- Q: Are graphite and carbon electrodes the same? What kinds of ore furnaces are used?

- The main components of carbon electrodes are graphite, carbon powder and other impurities which are not converted into graphite. The resistivity is higher than that of graphite electrode. These electrodes are mostly used in electric furnace steelmaking, smelting aluminium oxide and other electric arc furnaces.

- Q: What are the losses in graphite electrode?

- In what environment is the loss, friction, or in the case of high temperature, high temperature will be oxidized, and if in the case of friction, you can first use more wear-resistant graphite material. So please ask this question clearly, and then answer you, thank you.

- Q: What are the factors that affect the electrode wear rate of machine tools?

- In the pulse peak voltage, current and pulse width decreased, the electrode loss increase, and the heat produced from the processing of large pulse width, is conducive to the adsorption of copper electrode graphitization induced by carbon, which is commonly referred to as the covering effect".

- Q: How can I electroplate iron? I would like to use graphite as an electrode. Iron is plated on graphite with iron solution, so it can be processed into iron parts. I wonder if it can be done

- Iron plating can be, with 2 valence iron, but on the graphite joint force is good, it is difficult to say, electroplating is bad, peeling is also common. Relatively speaking, iron parts on nickel plating is relatively simple, also more applicable

- Q: Electrolysis of CuCl2 solutions with graphite electrodes

- After energization, electrolysis occurs, not ionizationIonization does not require energization, and can occur in aqueous or molten state.

- Q: I used 12V direct current, graphite electrode electrolysis sodium sulfide solution, the anode produced a large number of black material, this is why ah?

- Is this principle. Graphite is a layer, each layer, each carbon is SP2 hybrid, and around three carbon connected, finally, between layer and layer formed delocalized covalent bond, making layer and layer can be connected. However, the delocalized covalent bond is not very stable, in attracting Yang Jizheng charge, delocalized covalent bond will certain destruction, the force between the graphite layer and the layer becomes small or not, so as to open.The black stuff is graphite

Send your message to us

Graphite Electrodes Price - UHP with Nipples for Steel Plant

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords