High Carbon Graphite Electrode Cylinder Rod (RP HD HP UHP) Graphite Electrode Supplier

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Graphite Electrodes:

We have full set of production line for graphite electrodes. Our products are characterized by superior compact structure, good electrical and thermal conductivity, high resistance to oxidation and corrosion in high temperature. The regular power graphite electrodes are used in metallurgy industry for refining, such as EAF furnaces of steel plant and other applications. As one of the most professional graphite electrode manufacturers in China, passed ISO9001:2000 certified. We're glad to quote you a most competitive price according to your specification.

2.Main features of Graphite Electrodes:

1).Good electrical conductivity

2).High resistance to thermal shock

3).High mechanical strength

3. Graphite Electrodes Images:

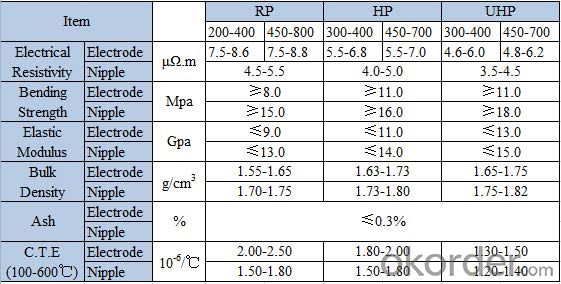

4. Graphite Electrodes Technical Parameters:

Diameter: from 50mm to 600mm (2" to 24")

Grades: including RP, HP, UHP.

Nipples: 3 TPI or 4 TPI.

Application: Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Graphite Electrodes is one of the large scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the skills of hardfacing process for wear-resistant alloy powder blocks?

- The hardfacing of wear-resistant alloy powder block is mostly made by carbon arc surfacing. General selection of graphite or carbon arc surfacing carbon rod and plate electrodes, which has good conductivity, high melting point;

- Q: Why should the carbon brush for the trolley be made of graphite?

- Graphite has good conductivity

- Q: Does the silicon carbide heat plant require a fine structure graphite electrode? What kind of graphite products do you need?

- But because the silicon carbide is too hard, it is difficult to machining, good workability, such as non special requirements, using graphite instead of silicon carbide, instead of the effect is not good, but can use a silicon carbide, easy processing, small life than silicon carbide.

- Q: Graphite electrode specifications, graphite electrode manufacturers which good?

- Graphite electrode to Qingdao Chenyang graphite Co., quality assurance, trustworthy, we have been purchasing graphite electrode for them, you can ask them,

- Q: The reason why graphite is used as electrode

- Good chemical stabilityGraphite has good chemical stability at room temperature. It can resist acid, alkali and organic solvent.

- Q: What's the use of carbon?

- High power graphite electrode. Allows the use of current density of 18 ~ 25A/ cm 2 graphite electrode, mainly used in steel-making high power arc furnace

- Q: Why is graphite a negative pole and copper is an anode?

- Graphite, as an electrode material, can conduct electricity, which belongs to an inert electrode. It only acts as a conductive agent, but does not participate in the electrolytic reaction process. So the anode is made, and copper is oxidized in the electrolysis of monovalent cations, so copper is used as the anode.

- Q: After vacuum melting of quartz crucible, there are three graphite electrode rods. What's the adjustment?

- The shorter one is the farther away from the other, and the shorter one is the shorter one

- Q: What do carbon products include?

- Carbon products can be divided into graphite electrode, carbon block, graphite anode, carbon electrode, paste, electric carbon, carbon fiber, special graphite, graphite heat exchanger and so on according to the use of products. Graphite electrode class can be divided into ordinary power graphite electrode according to the allowable current density.

- Q: What is the composition of petroleum coke and what is its use?

- Medium sulphur and common cooked coke; used in large quantities for aluminium smelting. High sulfur, ordinary coke is used in chemical production, such as the manufacture of calcium carbide, silicon carbide, etc., but also as a metal casting and other fuels. Most of the petroleum coke produced in China belongs to low sulfur coke, which is mainly used for smelting aluminium and making graphite.

Send your message to us

High Carbon Graphite Electrode Cylinder Rod (RP HD HP UHP) Graphite Electrode Supplier

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords