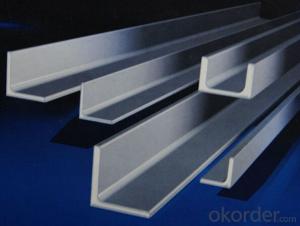

MS Hot Rolled Low Carbon Alloy Steel Angle

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering MS Hot Rolled Low Carbon Alloy Steel Angle at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

MS Hot Rolled Low Carbon Alloy Steel Angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's MS Hot Rolled Low Carbon Alloy Steel Angle are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

| EQUAL ANGLE STEEL | |||||

| size(mm) | a(mm) | a1(mm) | thickness(mm) | kg/m | length |

| 50*50*4 | 50 | 50 | 4 | 3.059 | 6m,9m,12m |

| 50*50*5 | 50 | 50 | 5 | 3.77 | 6m,9m,12m |

| 50*50*6 | 50 | 50 | 6 | 4.465 | 6m,9m,12m |

| 63*63*5 | 63 | 63 | 5 | 4.822 | 6m,9m,12m |

| 63*63*6 | 63 | 63 | 6 | 5.721 | 6m,9m,12m |

| 65*65*5 | 65 | 65 | 5 | 5 | 6m,9m,12m |

| 65*65*6 | 65 | 65 | 6 | 5.91 | 6m,9m,12m |

| 65*65*8 | 65 | 65 | 8 | 7.66 | 6m,9m,12m |

| 75*75*5 | 75 | 75 | 5 | 5.818 | 6m,9m,12m |

| 75*75*6 | 75 | 75 | 6 | 6.905 | 6m,9m,12m |

| 75*75*8 | 75 | 75 | 8 | 9.03 | 6m,9m,12m |

| 75*75*9 | 75 | 75 | 9 | 9.96 | 6m,9m,12m |

| 75*75*10 | 75 | 75 | 10 | 11.089 | 6m,9m,12m |

| 80*80*6 | 80 | 80 | 6 | 7.375 | 6m,9m,12m |

| 80*80*7 | 80 | 80 | 7 | 8.525 | 6m,9m,12m |

| 80*80*8 | 80 | 80 | 8 | 9.658 | 6m,9m,12m |

| 80*80*10 | 80 | 80 | 10 | 11.874 | 6m,9m,12m |

| 90*90*6 | 90 | 90 | 6 | 8.35 | 6m,9m,12m |

| 90*90*7 | 90 | 90 | 7 | 9.656 | 6m,9m,12m |

| 90*90*8 | 90 | 90 | 8 | 10.946 | 6m,9m,12m |

| 90*90*10 | 90 | 90 | 10 | 13.476 | 6m,9m,12m |

| 100*100*6 | 100 | 100 | 6 | 9.366 | 6m,9m,12m |

| 100*100*7 | 100 | 100 | 7 | 10.83 | 6m,9m,12m |

| 100*100*8 | 100 | 100 | 8 | 12.276 | 6m,9m,12m |

| 100*100*9 | 100 | 100 | 9 | 13.49 | 6m,9m,12m |

| 100*100*10 | 100 | 100 | 10 | 15.12 | 6m,9m,12m |

| 100*100*12 | 100 | 100 | 12 | 17.898 | 6m,9m,12m |

| 120*120*8 | 120 | 120 | 8 | 14.88 | 6m,9m,12m |

| 120*120*10 | 120 | 120 | 10 | 18.37 | 6m,9m,12m |

| 120*120*12 | 120 | 120 | 12 | 21.66 | 6m,9m,12m |

| 125*125*8 | 125 | 125 | 8 | 15.504 | 6m,9m,12m |

| 125*125*10 | 125 | 125 | 10 | 19.133 | 6m,9m,12m |

| 125*125*12 | 125 | 125 | 12 | 22.696 | 6m,9m,12m |

| 130*130*10 | 130 | 130 | 10 | 19.8 | 6m,9m,12m |

| 130*130*12 | 130 | 130 | 12 | 23.6 | 6m,9m,12m |

| 130*130*13 | 130 | 130 | 13 | 25.4 | 6m,9m,12m |

| 130*130*14 | 130 | 130 | 14 | 27.2 | 6m,9m,12m |

| 150*150*10 | 150 | 150 | 10 | 23 | 6m,9m,12m |

| 150*150*12 | 150 | 150 | 12 | 27.3 | 6m,9m,12m |

| 150*150*14 | 150 | 150 | 14 | 31.6 | 6m,9m,12m |

| 150*150*15 | 150 | 150 | 15 | 33.8 | 6m,9m,12m |

| 140*140*10 | 140 | 140 | 10 | 21.49 | 6m,9m,12m |

| 140*140*12 | 140 | 140 | 12 | 25.52 | 6m,9m,12m |

| 140*140*14 | 140 | 140 | 14 | 29.49 | 6m,9m,12m |

| 160*160*10 | 160 | 160 | 10 | 24.73 | 6m,9m,12m |

| 160*160*12 | 160 | 160 | 12 | 29.39 | 6m,9m,12m |

| 160*160*14 | 160 | 160 | 14 | 33.99 | 6m,9m,12m |

| 180*180*12 | 180 | 180 | 12 | 33.16 | 6m,9m,12m |

| 180*180*14 | 180 | 180 | 14 | 39.39 | 6m,9m,12m |

| 180*180*16 | 180 | 180 | 16 | 43.45 | 6m,9m,12m |

| 180*180*18 | 180 | 180 | 18 | 48.63 | 6m,9m,12m |

| 200*200*14 | 200 | 200 | 14 | 42.89 | 6m,9m,12m |

| 200*200*16 | 200 | 200 | 16 | 48.68 | 6m,9m,12m |

| 200*200*18 | 200 | 200 | 18 | 54.4 | 6m,9m,12m |

| 200*200*20 | 200 | 200 | 20 | 60.06 | 6m,9m,12m |

| 200*200*24 | 200 | 200 | 24 | 71.17 | 6m,9m,12m |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: How do you calculate the strength of a steel angle?

- To calculate the strength of a steel angle, you typically need to consider several factors, including the dimensions of the angle, the material properties of the steel, and the applied loads. The strength can be determined using mathematical equations, such as the yield strength or ultimate strength equations, which take into account the cross-sectional area and moment of inertia of the angle. Additionally, other factors like buckling or lateral torsional buckling may also need to be considered depending on the specific design requirements.

- Q: Can steel angles be painted or coated after installation?

- Yes, steel angles can be painted or coated after installation. Painting or coating steel angles after installation can provide additional protection against corrosion and enhance their aesthetic appeal. Prior to painting or coating, it is important to clean and prepare the surface by removing any dirt, rust, or contaminants. This can be done through techniques such as sandblasting, wire brushing, or using chemical cleaners. Once the surface is clean and dry, a suitable primer can be applied to promote adhesion and prevent corrosion. After the primer has dried, a final coat of paint or coating can be applied using a brush, roller, or spray. It is essential to choose a paint or coating that is specifically designed for steel and offers the desired level of protection and durability.

- Q: Can steel angles be used for mezzanine floors?

- Indeed, mezzanine floors can be constructed using steel angles. In construction, steel angles are widely employed as structural elements, particularly for mezzanine floors. They offer stability and support to the framework, enabling the expansion of floor space. With their robustness and durability, steel angles are ideal for bearing substantial loads and guaranteeing the security of the mezzanine floor. Furthermore, the fabrication and installation of steel angles are effortless, rendering them a cost-efficient option for the construction of mezzanine floors.

- Q: What are the different types of steel angles?

- There are several different types of steel angles, each designed for specific applications and purposes. Some of the common types include: 1. Equal angle: This type of steel angle has equal sides and is widely used in construction for structural support, bracing, and framing. 2. Unequal angle: Also known as L-shaped or unequal leg angle, this type of steel angle has unequal sides, with one longer side and one shorter side. It is commonly used in building construction to create corners, edges, and supports. 3. Stainless steel angle: Made from stainless steel, this type of angle offers excellent corrosion resistance and is commonly used in applications where exposure to moisture or chemicals is a concern, such as in marine environments or food processing facilities. 4. Galvanized angle: Galvanized steel angles are coated with a layer of zinc to provide protection against rust and corrosion. They are commonly used in outdoor and industrial applications where durability is essential. 5. Slotted angle: Slotted steel angles have holes or slots along their length, allowing for easy attachment and adjustment of components. They are commonly used in shelving systems, storage racks, and DIY projects. 6. Rolled steel angle: This type of angle is created by rolling steel into a specific shape, resulting in a uniform and smooth surface. Rolled steel angles are often used in manufacturing, machinery, and structural applications. 7. Structural angle: Structural steel angles are designed to bear heavy loads and provide structural support in construction projects. They are often used in building frames, bridges, and other infrastructure projects. These are just a few examples of the different types of steel angles available. The choice of angle will depend on the specific requirements of the project, including load capacity, corrosion resistance, and aesthetic considerations. Consulting with a professional or structural engineer can help determine the most suitable type of steel angle for a particular application.

- Q: Can steel angles be used for foundation reinforcement?

- Yes, steel angles can be used for foundation reinforcement. Steel angles are commonly used in construction for various purposes, including reinforcing foundations. They are often used to provide additional strength and stability to the foundation walls by connecting the horizontal and vertical elements. Steel angles can be easily installed and offer excellent resistance against bending and shearing forces, making them ideal for reinforcing foundations. Additionally, steel angles are durable, cost-effective, and readily available, making them a popular choice for foundation reinforcement in many construction projects.

- Q: Are steel angles suitable for manufacturing support brackets for conduits?

- Yes, steel angles are suitable for manufacturing support brackets for conduits. Steel angles are commonly used in construction and manufacturing industries due to their strength and durability. They provide excellent structural support and can withstand heavy loads. When used to manufacture support brackets for conduits, steel angles can effectively secure and hold the conduits in place, ensuring stability and preventing any potential damage or accidents. Additionally, steel angles can be easily customized to meet specific requirements, such as size, shape, and finish, making them a versatile choice for manufacturing support brackets for conduits.

- Q: Can steel angles be used for sign posts?

- Certainly! Sign posts can indeed utilize steel angles. Due to their robustness and endurance, steel angles are frequently employed in construction. They can effectively offer the required support and stability for sign posts, particularly in regions prone to strong winds or heavy traffic. Moreover, the versatility of steel angles shines through as they can be effortlessly welded or bolted together, presenting an adaptable choice for sign post installation. Furthermore, their immunity to corrosion guarantees a lengthier lifespan, thereby diminishing expenses associated with maintenance and replacement.

- Q: Are steel angles available in different colors?

- No, steel angles are typically available in their natural metallic color.

- Q: What are the common welding techniques used for steel angles?

- The common welding techniques used for steel angles include MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and stick welding (Shielded Metal Arc Welding - SMAW). MIG welding, also known as GMAW (Gas Metal Arc Welding), is a widely used technique that involves feeding a continuous wire electrode into the weld pool while an inert gas, such as argon or a mixture of argon and carbon dioxide, is used to shield the weld zone from atmospheric contamination. MIG welding is known for its ease of use, high welding speeds, and ability to handle thicker materials. TIG welding, also known as GTAW (Gas Tungsten Arc Welding), is a more precise welding technique that uses a non-consumable tungsten electrode to create the arc and a separate filler material if necessary. TIG welding provides excellent control over the weld pool and produces high-quality welds with minimal spatter. It is commonly used for thinner materials and applications that require a higher level of precision. Stick welding, also known as SMAW (Shielded Metal Arc Welding), is a versatile and widely used welding process. It involves striking an arc between a flux-coated electrode and the workpiece, creating a weld pool that is protected by the flux coating. Stick welding is known for its portability and ability to handle various materials and thicknesses. It is commonly used in construction, maintenance, and repair work. These welding techniques can be used for steel angles, which are often found in structural applications, such as frames, braces, and supports. The selection of the welding technique depends on factors such as the thickness of the steel angle, the required weld quality, and the specific application. It is important to consider the welding process, proper joint preparation, and welding parameters to ensure a strong and durable weld joint.

- Q: How do you calculate the shear strength of a steel angle?

- To calculate the shear strength of a steel angle, you need to consider the properties of the material and the geometry of the angle. The shear strength is a measure of the maximum load that the angle can withstand before it fails under shear stress. First, you need to determine the cross-sectional area of the steel angle. This can be calculated by multiplying the thickness of the angle by the length of one side. For example, if the angle has a thickness of 0.25 inches and a length of 4 inches, the cross-sectional area would be 1 square inch (0.25 inches x 4 inches). Next, you need to determine the shear stress that the angle can withstand. This is typically provided by the manufacturer and is given as a maximum value in pounds per square inch (psi) or megapascals (MPa). For example, let's say the shear stress is given as 30,000 psi. To calculate the shear strength, you simply multiply the cross-sectional area by the shear stress. Using the example values, the shear strength would be 1 square inch x 30,000 psi = 30,000 pounds. It is important to note that this calculation assumes the angle is loaded in a single shear plane and that the material is homogenous and isotropic. In real-world applications, there may be additional factors to consider, such as the presence of holes, welds, or other stress concentrations. In these cases, more complex calculations or testing may be required to determine the shear strength accurately.

Send your message to us

MS Hot Rolled Low Carbon Alloy Steel Angle

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords