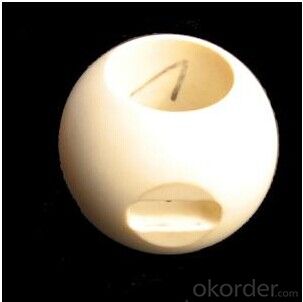

Monolithic Refractories Ceramic Lined Ceramic Ball Valve for Iron and Steel Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

Applied in any media, expect HF (Hydrofluoric Acid) or glass solution, with max. temperature up to 500°C or max pressure 5.0 Mpa, such as high corrosion, high attrition and middle pressure.

Structural: 3-part flange type float ball valve Flange standards follow DIN/ANSI/API/JIS

l Excellent wear-proof property of ceramic enables this valve have high reliability and prolonged lifespan which is 2-4times as much as Titannium Alloy and Monel Metal valve.

l Elastic O ring fit between metal part and ceramic part makes the whole part high sealing capacity, unables the two parts blind, and avoid the ball broken.

l Valve steams are selected among 316/316L stainless steel, HC alloy, Monel Alloy, structural ceramic.

l Completely symmetric design ensures dual leak-proof and two-direction usage to prolong its lifespan to twice.

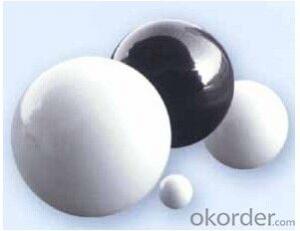

All parts that connect the medium are made of structural ceramics with extremely high chemical stability and hardness (HRC 90), which is only inferior to diamond. So the valve features exceedingly high wear-proof capability, corrosion resisting, enduring capability, good heat insulation, small thermal expansion.

The valve is unique in granule medium of high hardness, or erosive soft granule and is the only choice for such medium. They are wisely used in FDG System, Slag system and LNCFS in power plant, saline water and distilling processes in alkali works, paper pulp system in paper mill, and so on.

The ball is processed by advanced polishing equipment and technology that can ensure high circularity, good surface quality,.

The self-lubricating capability of ZrO2, ensure the good sealing performance between the ball and its seat. It is thoroughly free from the defects of easy leakage, big torque, non-resistance sealing surface comparing with metal sealing valve.

ZrO2 Composition Chart of MZ Ceramic Ball Valve

NO. | Physical Property | Parameter |

1 | Crystal | >85% cubic, the rest monoclinic |

2 | Lg. Loss | 0.8%-1.0% |

3 | Average | 0.4-0.7um |

4 | Apparent Density | >0.4g/cc |

5 | ZrO2 Purity | >99.95% |

6 | Tapped Density | >0.8g/cc |

- Q: How are monolithic refractories different from traditional brick refractories?

- Monolithic refractories differ from traditional brick refractories in terms of their composition and application method. While traditional brick refractories are made from individual bricks that are shaped and arranged to form a structure, monolithic refractories are a single, seamless material that is applied in a liquid or semi-liquid form and then cured or dried to form a solid mass. This allows monolithic refractories to be more versatile in terms of application, as they can be easily poured, sprayed, or troweled into complex shapes and installations. Additionally, monolithic refractories often offer better thermal insulation, higher resistance to thermal shock, and improved mechanical strength compared to traditional brick refractories.

- Q: How do monolithic refractories contribute to energy efficiency in iron and steel production?

- Monolithic refractories play a crucial role in enhancing energy efficiency in iron and steel production processes. These refractories are unshaped materials that are used to line the various components of furnaces, kilns, and other high-temperature equipment involved in the production of iron and steel. One way monolithic refractories contribute to energy efficiency is by providing excellent insulation. These materials have low thermal conductivity, which means they effectively reduce heat transfer from the furnace or kiln to the surrounding environment. By minimizing heat loss, monolithic refractories help maintain high temperatures within the production units, which in turn reduces the energy required to sustain the desired operating conditions. Furthermore, monolithic refractories offer superior resistance to thermal shock and wear, ensuring the longevity of the lining materials. This durability reduces the need for frequent repairs and replacements, leading to less downtime and increased operational efficiency. As a result, energy is conserved since the production units can continuously operate at optimal temperatures without interruptions. In addition, monolithic refractories have excellent resistance to chemical reactions, corrosion, and erosion caused by molten metals and slag. This resistance reduces the formation of cracks and defects in the lining, which can compromise the insulation and increase heat loss. By maintaining a robust and intact lining, monolithic refractories contribute to energy efficiency by minimizing heat escape and ensuring the efficient utilization of energy for the iron and steel production processes. Moreover, the use of monolithic refractories allows for design flexibility in the construction of furnaces and kilns. Their ability to be shaped and applied in various configurations enables the creation of optimized lining structures that enhance heat transfer and combustion efficiency. This flexibility empowers engineers and operators to design and modify the production units to maximize energy efficiency and minimize energy wastage. Overall, monolithic refractories contribute significantly to energy efficiency in iron and steel production by providing excellent insulation, durability, resistance to thermal and chemical degradation, and design flexibility. By reducing heat loss, minimizing repairs and replacements, and optimizing heat transfer, these refractories play a vital role in conserving energy and improving the overall sustainability of the iron and steel industry.

- Q: How do monolithic refractories perform in ladle lining applications in the iron and steel industry?

- Due to their excellent performance and durability, monolithic refractories are extensively utilized in ladle lining applications within the iron and steel industry. These refractories, which consist of a single material composition, offer numerous advantages over traditional brick linings. One significant benefit of employing monolithic refractories in ladle lining applications is their exceptional resistance to thermal shock. Ladles in the iron and steel industry experience extreme temperature fluctuations during the steelmaking process, including the pouring of molten metal and subsequent cooling. To guarantee the integrity of the ladle lining, monolithic refractories are specifically designed to endure these rapid temperature changes without cracking or spalling. In addition to their thermal shock resistance, monolithic refractories also demonstrate excellent resistance to chemical attack. The lining materials of ladles in the iron and steel industry are exposed to highly corrosive molten metal and slag, which can degrade over time. Nevertheless, monolithic refractories are formulated with high-quality raw materials that provide exceptional chemical stability, preventing the erosion and penetration of corrosive substances. Moreover, monolithic refractories offer superior mechanical strength in comparison to traditional brick linings. This is particularly crucial in ladle lining applications, as the lining must withstand the weight of the molten metal and the mechanical stresses associated with ladle handling and transportation. Monolithic refractories possess excellent load-bearing capabilities, ensuring the structural integrity of the ladle lining even under heavy loads. Another advantage of monolithic refractories is their ease of installation. Unlike brick linings, which require meticulous bricklaying, monolithic refractories can be installed using various techniques, such as gunning or casting. This allows for faster and more efficient lining repairs or replacements, reducing downtime during ladle maintenance. Consequently, iron and steel manufacturers can achieve increased productivity and cost savings. In conclusion, monolithic refractories perform exceptionally well in ladle lining applications within the iron and steel industry. Their resistance to thermal shock and chemical attack, superior mechanical strength, and ease of installation make them an ideal choice for ensuring the longevity and reliability of ladles in steelmaking operations.

- Q: How do monolithic refractories improve the efficiency of reheating furnaces in steel plants?

- Monolithic refractories improve the efficiency of reheating furnaces in steel plants by providing a superior lining material that offers high thermal conductivity, excellent heat resistance, and resistance to thermal shock. These refractories help to minimize heat loss and improve heat transfer, resulting in reduced energy consumption and increased furnace productivity. Additionally, the use of monolithic refractories eliminates the need for time-consuming bricklaying, allowing for quicker furnace start-up times and reduced maintenance downtime.

- Q: How do monolithic refractories perform in reheating furnace applications?

- Monolithic refractories perform exceptionally well in reheating furnace applications due to their excellent thermal shock resistance, high temperature stability, and superior insulation properties. They are able to withstand the extreme temperatures and rapid temperature changes that occur during the reheating process, ensuring consistent and efficient heat distribution. Additionally, their flexible and easy-to-install nature makes them an ideal choice for lining the complex geometries of reheating furnaces, resulting in improved performance and extended service life.

- Q: What are the main types of monolithic refractories used in the iron and steel industry?

- The main types of monolithic refractories used in the iron and steel industry are castables, plastic refractories, and ramming mixes.

- Q: Can monolithic refractories be used for lining iron and steel ladles during casting and pouring?

- Yes, when it comes to lining iron and steel ladles during casting and pouring, monolithic refractories are the go-to option. Unlike traditional refractory bricks, which consist of multiple pieces, monolithic refractories are composed of a single, uniform structure. Monolithic refractories are highly favored for ladle lining in iron and steel casting due to their numerous advantages. Firstly, they exhibit exceptional resistance to thermal shock, enabling them to endure the intense temperatures encountered during casting and pouring. This is of utmost importance since ladles are constantly exposed to extreme heat. Moreover, monolithic refractories provide superior resistance to erosion and corrosion, ensuring that the lining remains intact amidst the harsh conditions and chemical reactions that transpire when molten metal makes contact with the ladle. Additionally, they possess excellent thermal insulation properties, diminishing heat loss and enhancing energy efficiency throughout the casting process. Furthermore, monolithic refractories boast remarkable versatility, enabling easy installation, repair, and replacement. They can be molded and shaped to conform to the specific requirements of ladles, resulting in a snug and secure lining. This adaptability also enables swift maintenance and repair, minimizing downtime and optimizing productivity. In conclusion, monolithic refractories are the perfect choice for lining iron and steel ladles during casting and pouring. Their resistance to thermal shock, erosion and corrosion, thermal insulation properties, and ease of installation render them highly suitable for this demanding application.

- Q: How do monolithic refractories contribute to the reduction of heat loss in ladles and tundishes?

- Monolithic refractories play a crucial role in reducing heat loss in ladles and tundishes. These refractories are designed to provide excellent thermal insulation properties, which help to minimize the transfer of heat from the molten metal to the surrounding environment. One of the key factors contributing to heat loss in ladles and tundishes is conduction, where heat is transferred through direct contact with the refractory lining. Monolithic refractories are specifically engineered to have low thermal conductivity, meaning they are efficient at reducing heat transfer through conduction. This helps to maintain the desired temperature of the molten metal for longer periods, ultimately reducing energy consumption and improving overall process efficiency. Furthermore, monolithic refractories also aid in reducing heat loss through radiation. These refractories have high emissivity, which means they emit a significant amount of thermal radiation. This emitted radiation helps to create a heat shield around the molten metal, preventing the loss of heat to the surroundings. By effectively trapping the radiant heat, monolithic refractories contribute to maintaining the desired temperature in ladles and tundishes, thereby minimizing heat loss. In addition to their thermal insulation properties, monolithic refractories also offer excellent resistance to thermal shock and mechanical stress, ensuring they remain intact and functional in the harsh operating conditions of ladles and tundishes. This durability further contributes to the reduction of heat loss by preventing any cracks or gaps in the refractory lining that could facilitate heat transfer. In summary, monolithic refractories significantly contribute to the reduction of heat loss in ladles and tundishes by minimizing heat transfer through conduction and radiation. Their thermal insulation properties, combined with their resistance to thermal shock and mechanical stress, help to maintain the desired temperature of the molten metal, improve energy efficiency, and enhance the overall performance of these metallurgical vessels.

- Q: Can monolithic refractories be used for the lining of reheating furnaces and walking beam furnaces?

- Yes, monolithic refractories can be used for the lining of reheating furnaces and walking beam furnaces. Monolithic refractories are a type of refractory material that is characterized by its ability to be cast or gunned into place, rather than being made up of individual bricks or precast shapes. This makes them highly versatile and adaptable for various furnace applications, including reheating furnaces and walking beam furnaces. Reheating furnaces are used to heat metal products to a specific temperature before further processing, such as rolling or forging. The lining of these furnaces is subjected to high temperatures, thermal cycling, and mechanical stress. Monolithic refractories are well-suited for these conditions, as they have excellent thermal shock resistance and can withstand rapid temperature changes without cracking or spalling. Walking beam furnaces are used in the steel industry for the continuous heating and transport of steel slabs or billets. These furnaces require a lining material that can withstand the abrasion and mechanical stress caused by the movement of the material. Monolithic refractories with high abrasion resistance and good mechanical strength are ideal for the lining of walking beam furnaces. Additionally, monolithic refractories offer other advantages such as easy installation, reduced downtime for repairs, and improved energy efficiency. They can be tailored to specific furnace designs and can be easily repaired or replaced when necessary. In conclusion, monolithic refractories are a suitable choice for the lining of reheating furnaces and walking beam furnaces due to their ability to withstand high temperatures, thermal cycling, mechanical stress, and abrasion. Their versatility, ease of installation, and repair make them a preferred option for these furnace applications.

- Q: How do monolithic refractories provide thermal insulation in the iron and steel industry?

- Monolithic refractories provide thermal insulation in the iron and steel industry by forming a protective barrier that minimizes heat transfer. They have low thermal conductivity, preventing the rapid transfer of heat from the hot environment to the cooler surroundings. This insulation property helps to maintain high temperatures within furnaces and other equipment, ensuring efficient and consistent heat distribution for the iron and steel production processes.

Send your message to us

Monolithic Refractories Ceramic Lined Ceramic Ball Valve for Iron and Steel Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords