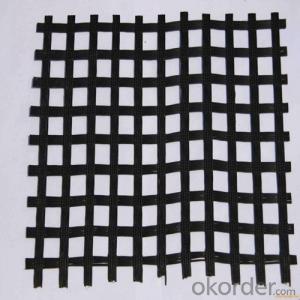

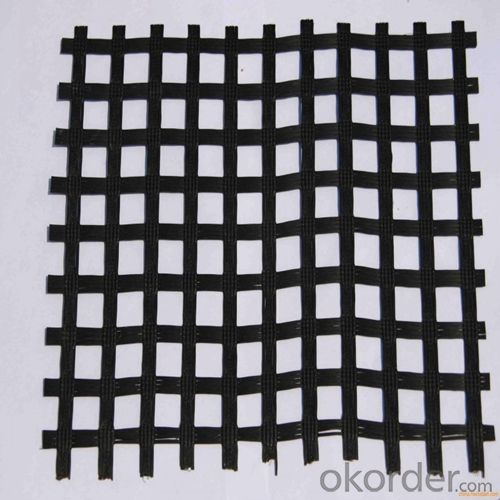

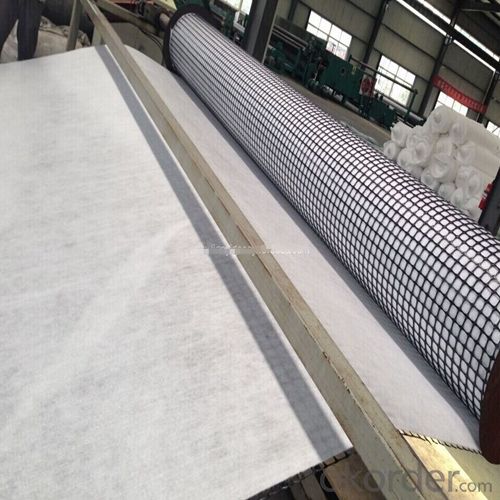

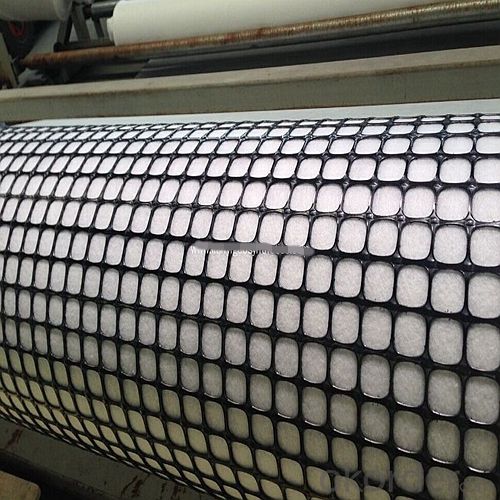

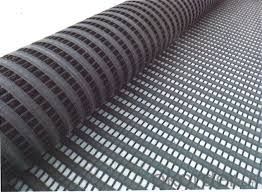

Mirafi Biaxial Polypropylene Geogrid with High Tensile Strength, Low Elongation, and Good Toughness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Place of Origin:

China (Mainland)

Model Number:

Biaxial

Material:

Fiberglass

Tensile strength:

100kn

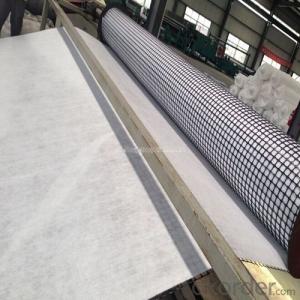

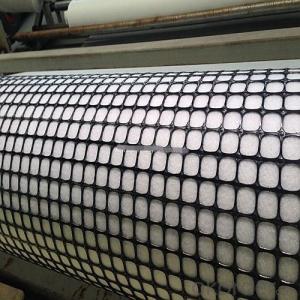

Roll Width:

3.95m

Roll length:

100 Meter

Porducts Description

Slopes and subgrades with rails are a serious problem in railroad construction. Under high

pressure the layers slide and deform consequently causing rail deformation, which requires

closing railroad segments for a long time. Geogrid application allows carrying out comlex

repair operations of the necessary road segment in shortest time (which is very essential

in transportation).

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

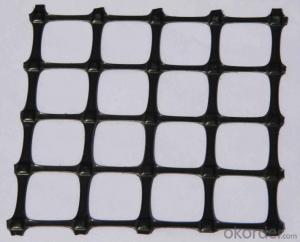

A: Yes, please check the pictures:

- Q: Geotextile CBR tear strength rate is how much

- Geotextile CBR bursting strength is generally in accordance with the national standard GB / T-2017 "geosynthetics static top breaking test (CBR method)" according to the national standard GB / T-2017 standard requirements of geotextile CBR strong pre-tension 20N. According to the national standard GB / T-2017 standard requirements of geotextile CBR strong rate of (50 ± 5) mm / min.

- Q: How do geotextiles help with erosion control in slope protection projects?

- Geotextiles are used in erosion control for slope protection projects by providing a barrier that stabilizes the soil, reduces water flow, and prevents sediment migration. They effectively control erosion by increasing soil cohesion, improving drainage, and enhancing vegetation growth, thereby preventing slope failure and minimizing the risk of erosion.

- Q: How do geotextiles help with sediment control in water bodies?

- Geotextiles help with sediment control in water bodies by acting as a physical barrier that prevents sediment from entering the water. The geotextiles are installed in strategic locations, such as along shorelines or in drainage areas, where they intercept and filter sediment-laden water. They allow water to pass through while trapping the sediment particles, thereby reducing the amount of sediment that reaches the water body. This helps to improve water quality, prevent erosion, and maintain the ecological balance of the water ecosystem.

- Q: What are the different factors to consider for geotextile selection in agricultural applications?

- When selecting geotextiles for agricultural applications, several factors need to be considered. These factors include the type and level of soil erosion, the desired drainage and filtration requirements, the expected load and stress levels on the geotextile, the potential for chemical exposure, the climate and weather conditions, and the longevity and durability needed for the specific agricultural application.

- Q: Geosynthetics direct shear instrument reference standards which

- Geosynthetics Direct shear test The abrasive characteristics of the sand / geotextile interface were measured by direct shear test of the standard sand / geotextile contact surface. Test Specimens: 1. Tile the specimen on a rigid horizontal base located in the lower part of the shear box, with the front end of the specimen, and the test leads: ISO.1, GB / T.1, ASTM / D5321, JTGE50T1129, SL / T235-1999. Clamped in front of the shear zone, the sample and the base between the adhesive with adhesive, after bonding the sample should be flat, without folding and folding, the test sample and the base is not allowed between the relative slip; 2. Install the upper shear box: with the pre-quasi-quality standard sand filled with the upper shear box, the thickness of 50mm, sand thickness should be uniform, after the density of the density of 1750kg / m3; 3. Install the horizontal loader , And apply 50KPa to the sample with a reference weight of 50KPa normal pressure.

- Q: How do geotextiles affect soil settlement?

- Geotextiles can help reduce soil settlement by providing reinforcement and stabilization. They act as a barrier that distributes the load from structures evenly, preventing differential settlement. Additionally, geotextiles improve soil drainage, allowing excess water to flow through while retaining the soil particles, which further aids in minimizing settlement.

- Q: Can geotextiles be used in soil erosion control on construction sites?

- Yes, geotextiles can be used in soil erosion control on construction sites. Geotextiles are permeable fabrics that can be placed on the soil surface to prevent erosion by stabilizing the soil and allowing water to pass through while retaining sediment. They are commonly used in construction sites to protect exposed soils from rainfall and runoff, reducing erosion and promoting vegetation growth.

- Q: What are the different geotextile installation techniques for steep slopes?

- There are several geotextile installation techniques that can be used for steep slopes. These include anchoring the geotextile with soil nails or ground anchors, using geotextile wraps or bags filled with soil to stabilize the slope, and installing geotextile mats or grids that are secured with stakes or pins. Additionally, erosion control blankets or mats can be used in combination with geotextiles to provide further slope stabilization.

- Q: What are the limitations of using geotextiles?

- Some limitations of using geotextiles include their limited strength and durability compared to traditional construction materials, their susceptibility to damage from UV radiation and chemical exposure, and their potential for clogging and reduced filtration efficiency over time. Additionally, geotextiles may not be suitable for applications requiring high tensile strength or for areas with high groundwater flow rates.

Send your message to us

Mirafi Biaxial Polypropylene Geogrid with High Tensile Strength, Low Elongation, and Good Toughness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords