Alloy Steel Ball Bearing Special Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

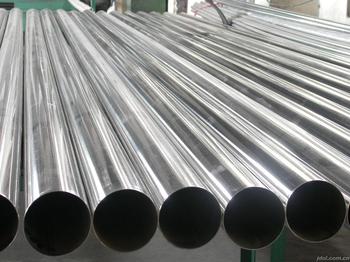

Product Description:

OKorder is offering Bearing Steelsat great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Bearing steels are used for ball and roller bearing applications and are comprised of low carbon steels and high carbon through harden able steel.First the famous 1C-1.5Cr steel from which the majority of bearings are made. Its structure is apparently well-understood and the focus is on purity in order to avoid inclusions which initiate fatigue during rolling contact. Then there is the M50 steel and its variants, from which bearings which serve at slightly higher temperatures in aeroengines are manufactured, based on secondary-hardened martensite.

Tapered roller bearing are generally used to support combined load mainly consisting of radial load. Their cups are separable for easy assembling ,During mounting and using, radial clearance and axial clearance can be adjusted and preloaded mounting can be made.

.

Product Advantages:

OKorder's Bearing Steels are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the different methods of surface hardening for special steel?

- There are several methods of surface hardening that can be used for special steel. These methods include: 1. Carburizing: This process involves heating the steel in a carbon-rich environment, such as a gas or liquid, to allow carbon atoms to diffuse into the surface of the steel. This increases the surface hardness and wear resistance of the steel. 2. Nitriding: Nitriding is a process where the steel is heated in a nitrogen-rich environment, causing nitrogen atoms to diffuse into the surface of the steel. This creates a hard, wear-resistant surface layer. 3. Induction hardening: In this method, an alternating current is passed through a coil to create a magnetic field, which induces electrical currents in the steel. The resistance to these currents generates heat, causing the surface of the steel to reach high temperatures and undergo rapid quenching, resulting in increased hardness. 4. Flame hardening: This process involves heating the surface of the steel using a flame or an oxy-fuel torch and then quenching it in water or oil. The rapid cooling from high temperatures helps to achieve surface hardening. 5. Laser hardening: Laser beams are used to heat a specific area of the steel surface, quickly raising the temperature and then rapidly cooling it with a coolant. This localized heating and cooling process increases the hardness of the treated area. 6. Plasma nitriding: In this method, the steel is placed in a low-pressure plasma chamber, where nitrogen ions bombard the surface of the steel, causing nitrogen to diffuse into the surface and form a hardened layer. Each of these methods has its advantages and is suitable for different applications and types of special steel. The choice of surface hardening method depends on factors such as the desired hardness, dimensional limitations, and the specific properties required for the application.

- Q: How does special steel perform under high temperatures?

- Special steel, also known as high-temperature steel, exhibits excellent performance under high temperatures. It maintains its strength, hardness, and resistance to deformation, making it suitable for various applications in extreme heat conditions. Additionally, special steel can withstand thermal stress and oxidation, ensuring its durability and reliability in high-temperature environments.

- Q: What are the common challenges in heat treating special steel?

- Heat treating special steel can present a variety of challenges. One common challenge is achieving the desired hardness and strength while maintaining the desired microstructure. Special steels often require specific heat treatment processes, such as quenching and tempering, to achieve the desired mechanical properties. However, the high alloy content of these steels can lead to difficulties in achieving uniform heat distribution and controlling the cooling rate during quenching, which in turn can result in inconsistent hardness and potential distortion. Another challenge in heat treating special steel is managing residual stresses. During the heating and cooling process, differential thermal expansion and contraction can cause stress to build up within the steel, leading to potential cracking or distortion. Special care must be taken to minimize these stresses through proper heat treatment techniques, such as preheating and controlled cooling rates. Special steels often have stringent cleanliness requirements, as impurities or non-metallic inclusions can negatively impact their mechanical properties. Ensuring the cleanliness of the steel prior to heat treatment can be challenging and may require additional steps such as degreasing, pickling, or using protective atmospheres during heat treatment. Furthermore, some special steels are highly sensitive to overheating, which can lead to grain growth and loss of desired properties. Precise temperature control and monitoring are crucial to prevent overheating and ensure consistent results. Lastly, special steels may have specific time-temperature transformation (TTT) and continuous cooling transformation (CCT) characteristics that need to be considered during heat treatment. Understanding and adhering to the appropriate heating and cooling cycles are essential for achieving the desired microstructure and properties. In summary, the common challenges in heat treating special steel include achieving the desired hardness and microstructure, managing residual stresses, ensuring cleanliness, preventing overheating, and adhering to specific time-temperature transformation characteristics. Overcoming these challenges requires expertise, precise control, and adherence to strict heat treatment protocols.

- Q: What are the different coating techniques used for special steel?

- There are several different coating techniques used for special steel, including electroplating, hot-dip galvanizing, powder coating, and thermal spray coating. Each technique has its own advantages and uses, depending on the desired outcome and the specific properties of the special steel being coated.

- Q: Can special steel be used in the production of surgical instruments?

- Yes, special steel can be used in the production of surgical instruments. Special steel alloys, such as stainless steel, are commonly used due to their desirable properties like corrosion resistance, strength, and their ability to be easily sterilized. These characteristics make special steel an ideal material for surgical instruments that require high precision and durability.

- Q: What are the requirements for special steel used in mining equipment?

- Special steel used in mining equipment needs to possess certain key requirements. Firstly, it must have high strength and toughness to withstand the harsh and demanding conditions present in mining operations. It should also exhibit excellent wear resistance to endure the abrasive nature of rocks and minerals. Additionally, corrosion resistance is crucial to prevent the steel from deteriorating due to exposure to water, chemicals, and other corrosive substances commonly found in mining environments. Finally, the special steel used in mining equipment should be capable of maintaining its mechanical properties at elevated temperatures, as mining processes often involve high heat generation. Overall, the requirements for special steel in mining equipment revolve around durability, wear resistance, corrosion resistance, and heat resistance.

- Q: How does nitriding steel improve hardness and wear resistance?

- Nitriding steel improves hardness and wear resistance by introducing nitrogen into the surface of the steel, forming a hard nitride layer. This layer increases the surface hardness of the steel, making it more resistant to wear, friction, and scratching. Additionally, the nitride layer also provides improved resistance against corrosion and high-temperature oxidation.

- Q: Is special steel suitable for manufacturing firearms?

- Yes, special steel is highly suitable for manufacturing firearms. Special steel alloys are specifically designed to possess exceptional properties such as high strength, hardness, and resistance to wear and corrosion. These characteristics are crucial for firearms as they need to withstand high pressures, recoil forces, and intense heat generated during firing. Special steel alloys, such as stainless steel or chrome-molybdenum steel, offer excellent tensile strength, allowing firearms to handle the immense pressure generated by the ignition of gunpowder. Moreover, the hardness of special steel ensures that the critical components, such as barrels and receivers, are durable and can withstand repeated use without deforming or cracking. Firearms also require resistance to wear and corrosion, as they are often exposed to harsh environments and various weather conditions. Special steel alloys are engineered to have superior resistance to both wear and corrosion, ensuring that the firearms remain functional and reliable even after prolonged use or exposure to moisture. Furthermore, special steel alloys can be easily machined and formed into complex shapes, allowing manufacturers to create intricate firearm components with precision. This versatility in manufacturing processes enables the production of firearms that meet stringent quality standards and precise specifications. In conclusion, special steel is unquestionably suitable for manufacturing firearms due to its exceptional strength, hardness, resistance to wear and corrosion, and ease of machining. These properties ensure the reliability, durability, and performance of firearms, making special steel an ideal material choice for this purpose.

- Q: Can special steel be used in the pharmaceutical manufacturing industry?

- No, special steel is not typically used in the pharmaceutical manufacturing industry. The industry requires specific materials, such as stainless steel, that meet strict regulatory requirements for cleanliness, corrosion resistance, and compatibility with pharmaceutical products.

- Q: How does special steel contribute to reducing product rejection rates in quality control?

- Special steel contributes to reducing product rejection rates in quality control by providing superior strength, durability, and resistance to wear and tear. These properties enable the production of high-quality components and eliminate common defects such as distortion, cracking, or premature failure. Additionally, special steel's precise composition and manufacturing processes ensure consistency and accuracy in the final products, reducing the likelihood of manufacturing errors and subsequent rejection during quality control inspections.

Send your message to us

Alloy Steel Ball Bearing Special Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords