Mill Steel Billets and Prime sSteel Raw Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mill Steel Billets and Prime sSteel Raw Materials

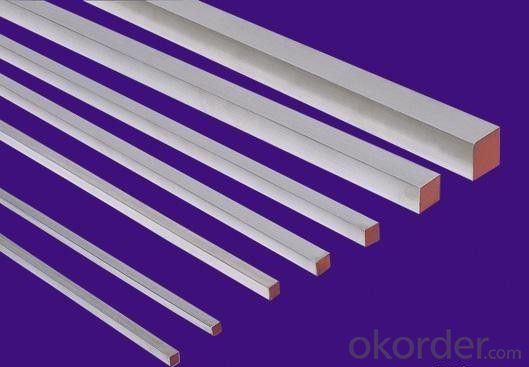

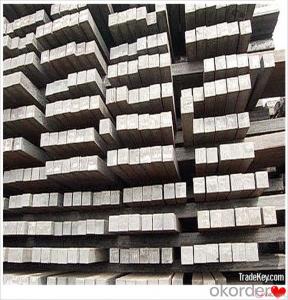

Specifications for Mill Steel Billets:

Type | Steel billet / Square steel/ Steel square bar |

Standard grade | 3SP/PS, 5SP/PS, Q195, Q235, Q255, Q275, 20MnSi etc. |

MOQ | 1000 MT |

Technique | Hot rolled, Continuous casting and rolling |

Size | 50*50mm ~ 160*160mm |

Length | 3~12m |

Packing | Loose packing, in bundle |

Payment terms | T/T, L/C at sight, Usance L/C |

Trade terms | EXW, FOB, CFR, CIF |

Trans terms | FIO, FILO, FLT |

Inspection | Third party inspection accepted |

Delivery time | 15-30 days, according to the quantity |

Applications | carbon structural steel, wire rod, rod, deformed bars, profile steel, machine parts, and steel moulds etc . |

Note | Customized service is available (for sizes,length and chemical components etc.). |

Datas for Mill Steel Billets

Steel Grade:

Steel Grade | C % | Mn % | Si % | S % | P % |

Q195 | 0.06-0.12 | 0.25-0.50 | 0.30 Max | 0.04 Max. | 0.04 Max. |

Q235 | 0.12-0.22 | 0.30-0.60 | 0.30 Max. | 0.04 Max. | 0.04 Max. |

Q255 | 0.18-0.28 | 0.40-0.70 | 0.30 Max. | 0.045 Max. | 0.050 Max. |

Q275 | 0.27-0.38 | 0.50-0.80 | 0.30 Max. | 0.045 Max. | 0.045 Max. |

3SP | 0.14-0.22 | 0.40-0.85 | 0.15-0.30 | 0.050 Max. | 0.040 Max. |

5SP | 0.28-0.37 | 0.50-1.00 | 0.15-0.30 | 0.050 Max. | 0.040 Max. |

20MnSi | 0.17-0.25 | 1.00-1.60 | 0.40-0.80 | 0.050 Max. | 0.050 Max. |

Main Features for Mill Steel Billets

Grade: Q195, Q235, Q255, Q275, 20MnSi

Chemical Composition: C, Mn, Si, S, P, B, Cr, C, Si, Mn, P, S, (B)

Shape: Square, Square

Length: 3-12m, 2-12m

Standard: GB, GB 1499-- steel billets and prime steel raw materials

Technique: Hot Rolled, Hot Rolled

Dimensions: square Steel billet Q235 Q275, 60*60mm-150*150mm

Alloy Or Not: Is Alloy, Is Alloy

Secondary Or Not: Non-secondary, Non-secondary

Type: steel billets and prime steel raw materials

FAQ

Q:How about your quality?

A:Quality is our culture, our products has to be checked with engineer, QC and sales, customer together, The products’ qualified rate need to be over 95%.

Picture:

- Q: How do steel sheets perform in high-pressure environments?

- In high-pressure environments, steel sheets demonstrate remarkable resilience and exceptional performance. Their inherent strength and durability enable them to withstand and effectively contain the immense pressure exerted upon them, making them the preferred choice in pressure vessels, pipelines, and industrial machinery. While the high-pressure environment subjects materials to significant stress, steel sheets possess the ability to resist deformation and maintain their structural integrity. Their exceptional tensile strength and capacity to withstand compressive forces without buckling or breaking establish them as a reliable option for withstanding high pressure. Moreover, steel sheets are renowned for their excellent corrosion resistance, a crucial characteristic in high-pressure environments. This resistance plays a pivotal role in preventing potential leaks or failures resulting from the weakening effects of corrosion. To further enhance their corrosion resistance, steel sheets can be coated or treated, making them even more suitable for demanding applications. Additionally, steel sheets offer a high level of versatility, readily fabricated into various shapes and sizes to meet precise requirements. This adaptability allows for the customization of steel sheets, ensuring optimal performance in a range of industrial settings and high-pressure environments. In conclusion, steel sheets exhibit exceptional reliability and excel in high-pressure environments. Their strength, durability, resistance to deformation, and corrosion resistance establish them as the preferred choice for applications requiring containment of high-pressure substances.

- Q: What is the average thickness of steel sheets?

- The average thickness of steel sheets can vary depending on various factors such as the specific type of steel, its intended application, and industry standards. However, in general, steel sheets can range in thickness from around 0.4 millimeters (0.016 inches) to several millimeters (0.1 inches or more). It is important to note that different industries and applications may have specific requirements for steel sheet thickness, so it is always best to consult relevant standards or specifications for accurate information.

- Q: Are steel sheets suitable for cryogenic applications?

- Yes, steel sheets are suitable for cryogenic applications. Steel has excellent mechanical properties, including strength and toughness, even at low temperatures. It can withstand extreme cold without becoming brittle, making it a reliable material for cryogenic storage tanks, pipelines, and other equipment used in industries such as aerospace, energy, and healthcare. Additionally, steel sheets can be fabricated and welded easily, making them a cost-effective choice for cryogenic applications.

- Q: Can steel sheets be formed into complex shapes?

- Yes, steel sheets can be formed into complex shapes through various metalworking processes such as bending, rolling, stamping, and laser cutting. These processes allow the steel sheets to be manipulated and transformed into intricate and custom shapes, meeting the specific design requirements. The malleability and strength of steel make it possible to form it into complex shapes without compromising its structural integrity. These capabilities are widely utilized in industries such as automotive, aerospace, construction, and manufacturing, where complex and precise components are required.

- Q: Can steel sheets be used in the energy sector?

- Yes, steel sheets can be used in the energy sector. Steel is a versatile material that offers several advantages for various applications in the energy industry. It is commonly used in the construction of power plants, transmission towers, and infrastructure for renewable energy sources such as wind turbines and solar panels. In power plants, steel sheets are used in the fabrication of boilers, turbines, and other components. Steel's high strength and durability make it suitable for withstanding the high temperatures and pressures involved in power generation processes. It also offers resistance to corrosion and erosion, ensuring the longevity of critical equipment. Steel sheets are also utilized in the construction of transmission towers and substations. These structures support power transmission lines and facilitate the efficient flow of electricity across long distances. Steel's strong mechanical properties make it an ideal choice for these applications, as it can withstand the weight and stresses imposed by power transmission infrastructure. Furthermore, steel sheets are vital in the manufacturing of wind turbines and solar panels. In wind turbines, steel is used for the tower structure, which must be strong enough to support the weight of the rotor and withstand the loads from wind forces. Additionally, steel sheets are used in the construction of solar panel frames, providing rigidity and stability for the photovoltaic modules. Overall, steel sheets are widely used in the energy sector due to their strength, durability, and resistance to various environmental factors. The versatility of steel makes it a reliable choice for a range of applications, helping to support the generation and transmission of energy in both conventional and renewable energy sources.

- Q: What is the tensile strength of the steel sheets?

- The tensile strength of steel sheets varies based on the specific grade and thickness of the steel. In general, steel sheets have a tensile strength that falls between 370 and 1,500 megapascals (MPa). However, it is important to note that different types of steel sheets possess different tensile strength values. For instance, low carbon steel sheets typically exhibit a tensile strength ranging from 370 to 550 MPa, while high-strength low alloy (HSLA) steel sheets can possess tensile strengths that span from 450 to 1,200 MPa. Furthermore, the thickness of the steel sheets also impacts their tensile strength, with thicker sheets generally displaying higher tensile strength values. Therefore, it is critical to refer to the specifications provided by the manufacturer or supplier of the steel sheets to ascertain the precise tensile strength for a particular grade and thickness.

- Q: What are the different sheet metal welding techniques for steel sheets?

- Steel sheets can be joined using various sheet metal welding techniques. The most commonly used methods are as follows: 1. MIG welding, also known as Gas Metal Arc Welding (GMAW), involves the use of a continuous wire electrode to create an arc and join the steel sheets. This technique is versatile and efficient, suitable for both thin and thick sheets. 2. TIG welding, or Gas Tungsten Arc Welding (GTAW), utilizes a non-consumable tungsten electrode to create an arc and join the steel sheets. It produces high-quality welds with excellent control, making it ideal for thin or delicate sheet metal. 3. Resistance Spot Welding (RSW) involves applying pressure and passing a high electrical current through the steel sheets using two electrodes. This causes the sheets to fuse together swiftly and cost-effectively. It is commonly used in the automotive and manufacturing industries. 4. Laser Welding employs a high-energy laser beam to melt and join the steel sheets. The technique offers precise control, high welding speeds, and minimal heat input, making it suitable for thin and highly reflective materials. 5. Electron Beam Welding (EBW) utilizes a focused beam of high-velocity electrons to create a weld. It offers deep penetration and is often used for thick steel sheets or applications requiring high-quality welds. 6. Plasma Arc Welding (PAW) is similar to TIG welding but utilizes a plasma arc to create a weld. This technique provides higher welding speeds and can be used for both thick and thin steel sheets. The choice of welding technique depends on various factors such as the thickness of the steel sheets, desired weld quality, production volume, and available equipment. Each method has its own advantages and limitations.

- Q: Can steel sheets be used for manufacturing containers or packaging?

- Yes, steel sheets can be used for manufacturing containers or packaging. Steel is a durable and strong material that can provide adequate protection and security for various products during transportation and storage. Additionally, steel sheets are resistant to corrosion, making them suitable for long-term use in demanding conditions.

- Q: Can steel sheets be used for soundproofing purposes?

- Steel sheets are indeed suitable for soundproofing purposes. Due to its density and rigidity, steel effectively blocks the transmission of sound waves. When utilized in soundproofing applications, steel sheets aid in reducing the amount of sound that penetrates through walls, floors, or ceilings. They can be installed as a barrier or added as an extra layer to existing structures, thus enhancing their soundproofing capabilities. However, it is essential to acknowledge that relying solely on steel sheets may not guarantee complete soundproofing, as sound can still travel through alternate pathways like windows or doors. Therefore, a comprehensive soundproofing approach may entail combining steel sheets with other sound-absorbing materials, such as acoustic foam or insulation, to achieve optimal outcomes.

- Q: Can steel sheets be used for reinforcing concrete structures?

- Yes, steel sheets can be used for reinforcing concrete structures. Steel sheets, commonly referred to as steel plates or steel mesh, are often used as reinforcement in concrete structures to enhance their tensile strength and durability. The steel sheets are typically placed within the concrete to provide additional support, preventing cracking and increasing the overall structural integrity of the concrete.

Send your message to us

Mill Steel Billets and Prime sSteel Raw Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords