Anodized Aluminum Profiles - Mill Finished Aluminum Profile in China All Alloy Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium is a relatively soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray, depending on the surface roughness. It is nonmagnetic and does not easily ignite. A fresh film of aluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (as much as 98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel. It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spelling differences) are alloys in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable.

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

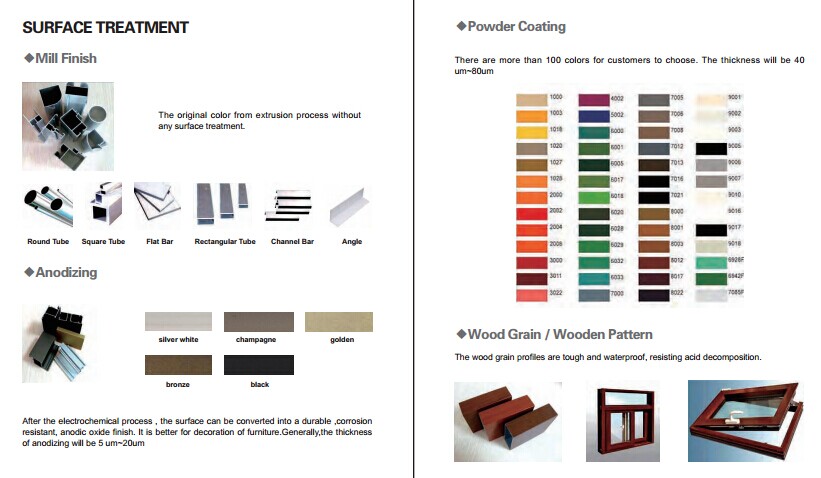

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5-6 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

Products are exported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam, Nigeria etc, over 100 countries and regions all over the world.

1. Application of Mill Finished Aluminum Profile in China all Alloy Series

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

2. Feature of Mill Finished Aluminum Profile in China all Alloy Series

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

3. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

4. Image of Mill Finished Aluminum Profile in China all Alloy Series

5. Package and shipping of Mill Finished Aluminum Profile in China all Alloy Series

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

6. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Aluminum profile connecting piece

- Very little to buy this alone, and only with industrial aluminum suppliers. - selling on Taobao is also a way if the price is appropriate.

- Q: What are the different cutting options available for aluminum profiles?

- There are several cutting options available for aluminum profiles, depending on the specific requirements of the project. Some of the common cutting methods include: 1. Miter Saw: This is a popular cutting option for aluminum profiles. A miter saw uses a circular blade to make precise angled cuts, allowing for accurate and clean cuts on aluminum profiles. 2. Chop Saw: Similar to a miter saw, a chop saw is also commonly used for cutting aluminum profiles. It uses a circular blade to make straight cuts at 90-degree angles. It is efficient and can handle larger aluminum profiles with ease. 3. Bandsaw: A bandsaw is another versatile cutting option for aluminum profiles. It uses a continuous looped blade to make straight cuts. It provides more flexibility in terms of cutting angles and is capable of cutting thicker aluminum profiles. 4. CNC Cutting: Computer Numerical Control (CNC) cutting is a highly accurate and precise cutting method for aluminum profiles. It involves using a computer-controlled cutting machine that can follow complex design patterns. This method is ideal for intricate and detailed cuts, ensuring high precision and repeatability. 5. Laser Cutting: Laser cutting is a popular cutting option for aluminum profiles as it offers a high level of precision and clean cuts. It involves using a focused laser beam to melt or vaporize the aluminum, resulting in smooth and accurate cuts. Laser cutting is suitable for both simple and complex designs. 6. Waterjet Cutting: Waterjet cutting is a versatile cutting method that uses a high-pressure jet of water mixed with abrasive particles to cut through aluminum profiles. It can handle various thicknesses and shapes, providing precise cuts without generating heat or altering the properties of the aluminum. 7. Shearing: Shearing is a basic cutting method that involves using sharp blades to trim or cut aluminum profiles. It is commonly used for straight cuts and is suitable for thinner aluminum profiles. 8. Plasma Cutting: Plasma cutting uses a high-velocity jet of ionized gas to cut through aluminum profiles. It is suitable for thicker profiles and allows for faster cutting speeds compared to other methods. These are just some of the cutting options available for aluminum profiles. The choice of method depends on factors such as the desired cut type, accuracy requirements, profile thickness, and complexity of the design. It is important to consider these factors and consult with professionals to determine the most suitable cutting option for a specific project.

- Q: Are aluminum profiles suitable for use in chemical processing environments?

- Yes, aluminum profiles are suitable for use in chemical processing environments. Aluminum is a versatile and corrosion-resistant material that can withstand exposure to a wide range of chemicals. It has excellent resistance to many common chemicals, including acids, bases, and solvents. Additionally, aluminum profiles can be further protected by applying specialized coatings or finishes, such as anodizing, which enhances their resistance to chemical corrosion. Furthermore, aluminum profiles offer other advantages in chemical processing environments, such as their lightweight nature, high strength-to-weight ratio, and ease of fabrication. These qualities make aluminum profiles a preferred choice for various applications in chemical processing industries, including the construction of tanks, piping systems, and process equipment.

- Q: Top 10 ranking enterprises of aluminum profiles in China

- Don't just look at rankings, which is something false, we all know in the aluminum industry, aluminum extrusion and some more than 50 units, annual production capacity of 90 thousand tons, were stronger than some ten enterprises inside the above you can see, but in the rankings but no, this ranking is water.

- Q: This question asks for the standard specifications and measurements of aluminum profiles that are frequently utilized in construction projects.

- <p>Aluminum profiles used in construction come in various specifications and measurements. Commonly, they are categorized by series such as 6060, 6061, 6063, and 6082, each with different mechanical properties. Sizes can range from small profiles like 20x20mm to large ones like 200x200mm or more. Thicknesses typically vary from 1mm to 6mm, depending on the structural requirements. Lengths can be customized but are generally available in standard lengths such as 6 meters. The profiles are measured in terms of their width, height, and thickness, and they are designed to meet specific load-bearing and aesthetic needs in construction. It's important to consult with suppliers or construction specifications for the exact measurements required for a particular project.</p>

- Q: Are aluminum profiles suitable for use in roofing or wall systems?

- <p>Yes, aluminum profiles are commonly used for both roofing and wall systems due to their durability, corrosion resistance, and lightweight properties. They offer a modern aesthetic and can be easily integrated into various architectural designs. Aluminum profiles are also known for their strength and flexibility, allowing for the creation of complex shapes and structures. Additionally, they require minimal maintenance and can withstand harsh weather conditions, making them a popular choice for construction projects.</p>

- Q: How is the tonnage of aluminum profile extrusion machine calculated? Do you have any formulas? For example, 30*60 industrial profiles, the need for a large tonnage of extrusion machine can be done?

- This section is almost the same as a 1500-2000 ton extruder.In general, the extrusion ratio of 6063 profiles will be controlled at around 30-150,That is, the section of rice weight / casting rod of rice weight, or section section area / aluminum bar cross-sectional area.

- Q: What are the different types of corner connectors used with aluminum profiles?

- There are several different types of corner connectors used with aluminum profiles, including corner brackets, corner blocks, T-slot corner connectors, and corner gussets. These connectors help to create strong and stable joints between aluminum profiles, allowing for the construction of various structures and frameworks.

- Q: What do the 6063 and T5 represent in the aluminum profile 6063-T5?

- Alloy number: our country's current general is the American Aluminum Association "Aluminium Association" numberExamples are as follows: 1070-H14 (pure aluminum)2017-T4 (heat treatment alloy)3004-H32 (non heat treated alloy)2.1 first digit: indicates the main addition of alloying elements1: pure aluminum2: the main alloy element added copper3: the main alloying elements are manganese or manganese and magnesium4: the main alloy element is added silicon

- Q: How to use aluminum profile on the side of roller conveyor?

- In fact, nothing, just use the welding rod along the side welding on the line

Send your message to us

Anodized Aluminum Profiles - Mill Finished Aluminum Profile in China All Alloy Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords