Mill Finished Aluminum Floor Transition Strips AA3XXX for Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Mill Finished Aluminum Strips AA3xxx Used for Coating Description

Mill Finished Aluminum Strips AA3xxx Used for Coating is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. Mill Finished Aluminum Strips AA3xxx Used for Coating is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features ofMill Finished Aluminum Strips AA3xxx Used for Coating

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

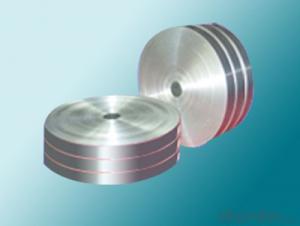

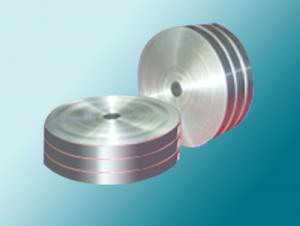

3. Image of Mill Finished Aluminum Strips AA3xxx Used for Coating

4.Mill Finished Aluminum Strips AA3xxx Used for Coating Specification

Alloy | AA3xxx (AA3003, AA3105, AA3005) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Mill Finished Aluminum Strips AA3xxx Used for Coating

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Mill Finished Aluminum Strips AA3xxx Used for Coating.

B.When will you deliver the products?

Mill Finished Aluminum Strips AA3xxx Used for Coating will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: What characteristics of aluminum strips make them ideal for construction purposes?

- <p>Aluminum strips are suitable for use in construction due to several key properties. They are lightweight, which reduces the load on structures and makes them easier to handle and install. They possess high strength-to-weight ratio, ensuring durability and resistance to deformation. Aluminum strips are also corrosion-resistant, protecting against rust and other forms of decay, which is crucial for long-term structural integrity. Their excellent thermal conductivity aids in heat management, which is beneficial in both heating and cooling applications. Furthermore, aluminum strips are malleable and can be easily shaped and bent, allowing for versatile design and construction. Lastly, they are recyclable, contributing to sustainability and reducing environmental impact.</p>

- Q: What are the safety regulations concerning the use of aluminum strips in construction?

- <p>Yes, safety regulations apply to the use of aluminum strips in construction work. These regulations vary by country and region but generally include adherence to material standards, proper handling and installation procedures, and compliance with electrical and fire safety codes. For instance, in the United States, the Occupational Safety and Health Administration (OSHA) sets guidelines for safe construction practices, which may include specific requirements for using aluminum strips. Additionally, the American Society for Testing and Materials (ASTM) provides material standards for aluminum strips used in construction. It is crucial to consult local building codes and industry standards to ensure compliance with all applicable safety regulations when using aluminum strips in construction projects.</p>

- Q: Is it possible to use aluminum strips as a material for wall cladding?

- <p>Yes, aluminum strips can be used for wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for both interior and exterior applications. Aluminum strips are also easy to install and maintain, and they can be painted or finished in various ways to match different architectural styles. However, it's important to ensure that the aluminum is of high quality and that the installation is done correctly to achieve a secure and aesthetically pleasing result.</p>

- Q: Does aluminum corrode in a manner similar to rusting?

- <p>Aluminum does not rust in the same way as iron or steel. Instead, aluminum reacts with oxygen in the air to form a thin, protective layer of aluminum oxide on its surface. This oxide layer prevents further corrosion, unlike rust which can compromise the integrity of iron and steel. While aluminum can tarnish or become discolored due to exposure to certain elements or chemicals, it does not rust in the traditional sense.</p>

- Q: Explain the relationship between aluminum strips and aluminum foil, including their similarities and differences.

- <p>Aluminum strips and aluminum foil are both made from the same material, aluminum, but they differ in their form and thickness. Aluminum strips are typically thin, flat pieces of aluminum that are longer and narrower compared to aluminum foil. They are often used in industrial applications, such as in the manufacturing of electrical components or as a conductive material in various devices. Aluminum foil, on the other hand, is much thinner and is commonly used in cooking, food storage, and packaging due to its high barrier properties against air and moisture. While aluminum strips may be thicker and more rigid, aluminum foil is lightweight and flexible, making it suitable for a wide range of consumer and household uses.</p>

- Q: Explain how aluminum strips play a role in enhancing energy efficiency.

- <p>Aluminum strips contribute to energy efficiency primarily through their use in thermal insulation and reflective properties. In building construction, aluminum strips can be used to create airtight seals around windows and doors, reducing heat transfer and drafts, which in turn lowers the need for heating or cooling systems. Additionally, aluminum's reflective nature can be utilized in radiant barriers, which reflect heat away from buildings, reducing the energy required for cooling. In electrical applications, aluminum strips are used in high-efficiency transformers and electrical conductors due to their high conductivity and light weight, reducing energy loss during transmission. Overall, aluminum strips enhance energy efficiency by minimizing heat loss and improving the performance of energy systems.</p>

- Q: The user is asking if it is possible to apply paint or stain to aluminum siding after it has been installed.

- <p>Yes, you can paint or stain aluminum siding after installation, but it requires proper preparation. The surface must be thoroughly cleaned to remove any dirt, grease, or factory applied oils. A high-quality primer compatible with aluminum is essential before applying paint or stain. Use a paint or stain specifically designed for metal surfaces to ensure adhesion and durability. Always follow the manufacturer's instructions for the best results.</p>

- Q: Can aluminum foil be used instead of aluminum strips in specific applications?

- <p>Yes, aluminum foil can be used as a substitute for aluminum strips in certain applications, particularly in DIY projects or crafts where the structural strength requirements are not high. However, it's important to note that aluminum foil is thinner and less rigid than aluminum strips, which may limit its use in applications requiring greater strength or durability. Always consider the specific requirements of your project before deciding to use aluminum foil as a substitute.</p>

- Q: This question asks for the primary applications or purposes of using aluminum strips.

- <p>Aluminum strips are primarily used in various industries due to their lightweight, corrosion resistance, and high strength-to-weight ratio. They are commonly used in construction for framing and cladding, in the automotive industry for vehicle bodies and parts, in aerospace for aircraft components, and in electrical applications for wiring and conductors. Additionally, aluminum strips are employed in packaging, such as food and beverage cans, and in the manufacturing of electronic devices and heat exchangers. Their versatility makes them a popular choice for many applications where durability and performance are required.</p>

- Q: Are aluminum strips suitable for use as an insulating material on walls?

- <p>Aluminum strips are not typically used for wall insulation. Insulation materials are designed to provide thermal resistance and prevent heat transfer, whereas aluminum is a good conductor of heat, which would not effectively insulate a wall. Instead, materials like fiberglass, mineral wool, or polystyrene are commonly used for wall insulation as they have low thermal conductivity and can effectively reduce heat transfer.</p>

Send your message to us

Mill Finished Aluminum Floor Transition Strips AA3XXX for Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords