Flooring Transition Strips Aluminum AA1070

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

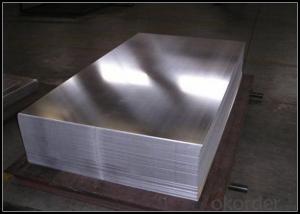

1. Specifications of Aluminum Strips AA1070

Alloy Number | AA1070 |

Temper | Temper H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness | 0.10-500mm |

Diameter | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

Special specification is available on customers' requirements.

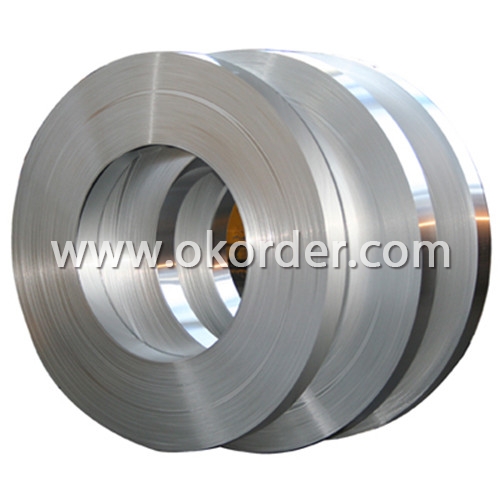

2. Usage/Applications of Aluminum Strips AA1070

Aluminum strips are widely used for PS printed materials substrate, building decoration materials, stamping products, building mirror materials, nameplate, insulation materials, aluminum plastic composite material, capacitor strip, transformer strip, welding parts, heat exchanger, clock surface and disk, kitchen utensils, reflecting apparatus etc.

3. Packaging & Delivery of Aluminum Strips AA1070

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 30 days after getting the buyer's payment.

4. Production Flow of Aluminum Strips AA1070

Rolling--Annealing--Slitting—Sawing, Cut-To-Length, Shearing

- Q: What benefits are associated with the use of aluminum strips on the exterior walls of buildings?

- <p>Aluminum strips for exterior walls offer several advantages, including durability, resistance to corrosion and weathering, and low maintenance requirements. They are lightweight, which can reduce the load on the building structure. Aluminum strips also provide excellent heat insulation properties, contributing to energy efficiency. Additionally, they can be easily shaped and bent, allowing for versatile and modern architectural designs. The recyclability of aluminum makes it an environmentally friendly choice, and its non-combustible nature enhances safety in construction.</p>

- Q: Is it possible to utilize aluminum strips for creating decorative patterns or designs on the exterior of buildings?

- <p>Yes, aluminum strips can be used to create patterns or designs on building exteriors. They are lightweight, durable, and resistant to corrosion, making them ideal for outdoor applications. Aluminum strips can be cut, bent, and shaped into various forms to create intricate designs and patterns. They can also be anodized or painted to achieve different colors and finishes, enhancing the aesthetic appeal of the building's exterior.</p>

- Q: What specific tools or equipment are necessary to install aluminum strips?

- <p>To install aluminum strips, you generally need a few basic tools. A measuring tape is essential for accurate placement. A utility knife or a metal cutting tool is necessary for cutting the strips to the correct length. A level is crucial to ensure the strips are straight. A rubber mallet or a hammer can be used to secure the strips in place. Adhesive, such as construction adhesive or double-sided tape, is often required to attach the strips. Safety equipment like gloves and safety goggles should be worn to protect against sharp edges and debris.</p>

- Q: Explain how aluminum strips can impact the waterproofing process and their role in construction.

- <p>Aluminum strips play a crucial role in waterproofing by serving as a barrier against water penetration. They are often used in construction to seal joints and seams where water could potentially infiltrate. These strips are durable, corrosion-resistant, and flexible, making them ideal for maintaining a watertight seal even under fluctuating temperatures and structural movements. They can be used in conjunction with other waterproofing materials such as sealants and membranes to create a robust defense against water damage. By preventing water from entering buildings or structures, aluminum strips help to protect against moisture-related issues like mold, structural decay, and deterioration, thereby enhancing the longevity and integrity of the construction.</p>

- Q: What are the environmentally friendly options for aluminum strips?

- <p>Yes, there are environmentally friendly types of aluminum strips. Recycled aluminum strips are more eco-friendly as they require significantly less energy to produce compared to virgin aluminum. Additionally, using aluminum strips with a high recycled content reduces waste and conserves natural resources. Another option is to look for aluminum strips that are produced using renewable energy sources, which further reduces their carbon footprint. Lastly, choosing aluminum strips with a lower coating or treatment that is biodegradable or has a lower environmental impact can also contribute to their environmental friendliness.</p>

- Q: This question asks for the most suitable type of aluminum strip for outdoor applications.

- <p>The best type of aluminum strip for exterior use is typically 3003-H14 alloy. This alloy is known for its excellent corrosion resistance, which is crucial for outdoor applications where the strip may be exposed to various weather conditions. It also offers good formability, making it easy to shape and bend for various construction and architectural purposes. Additionally, 3003-H14 aluminum strip has good weldability, which is beneficial for applications where joining is required. It is commonly used for roofing, siding, and other exterior applications due to its durability and weather-resistant properties.</p>

- Q: This question asks for the various types of insulation materials that are created using aluminum strips.

- <p>Aluminum strips are used in the production of several types of insulation materials. One common type is reflective insulation, which uses aluminum's reflective properties to reduce heat transfer. This can be found in the form of foil insulation or radiant barrier insulation. Another type is aluminum foil-backed insulation, often used in HVAC systems to prevent heat loss. Additionally, aluminum is a component in some types of flexible duct insulation, providing both thermal and acoustic insulation. Lastly, aluminum is used in certain types of thermal insulation boards, which are used in construction to provide thermal resistance. These materials are valued for their durability, resistance to corrosion, and effectiveness in thermal management.</p>

- Q: Is it possible to utilize aluminum strips as decorative elements within a home?

- <p>Yes, you can use aluminum strips to make decorative accents for your home. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion. It can be used to create modern and sleek accents, such as trims, wall art, or even furniture accents. Due to its malleability, aluminum can be shaped into various designs and finishes, allowing for a wide range of decorative possibilities. Ensure that the aluminum strips are properly secured and finished to prevent any sharp edges and to maintain a polished look.</p>

- Q: What factors should be considered to determine if an aluminum strip is suitable for a specific application?

- <p>To determine if a certain type of aluminum strip is suitable for your application, consider the following factors: mechanical properties such as strength and ductility, corrosion resistance, thermal conductivity, and electrical conductivity. Assess the strip's dimensional tolerances and surface finish to ensure they meet your requirements. Check if the strip's formability and weldability align with your manufacturing processes. Also, consider the strip's weight and cost-effectiveness. It's advisable to consult with a material scientist or supplier who can provide specific recommendations based on your application's unique needs.</p>

- Q: This question asks for methods to identify if the roof material is aluminum strips.

- <p>To determine if your roof is made of aluminum strips, you can look for the following characteristics: 1) The roof has a shiny, metallic appearance, which is typical of aluminum. 2) The strips are lightweight and flexible, making them easy to handle. 3) They are often interlocking, which is a common feature of aluminum strip roofing. 4) Check for any manufacturer's markings or labels that might indicate the material. If you're unsure, a professional roof inspector can help confirm the material by examining the roof closely or taking a small sample for testing.</p>

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 2002 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Flooring Transition Strips Aluminum AA1070

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords