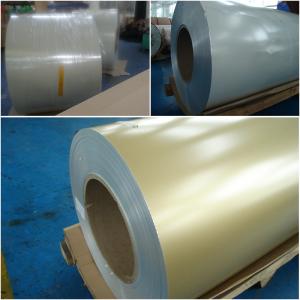

Brushed Aluminum Trim Strips - Hot Sale Wooden Grain Color Coated Prepainted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wooden pattern coated Aluminum coil /anodized aluminum coil 1100/3003 :

Our PVDF coated color aluminum coil is made of high-performance aluminum sheet and PVDF coating through advanced roller coating process.

Features:

1) Wear resistance 2) impact resistance 3) highly tensile strength 4) easy fabricating 5) UV resistance 6) weather resistance 7) corrosion- resistance 8) various colors

Aluminum foil range:

Thickness: 0.18mm-1.6mm

General Width: 1240mm, 1270mm, 1520mm, 1570mm, other special widths according to customer requirements;

Aluminum alloy: 1100,3003,8011,3105,5052, other alloys according to customer requirements.

Applications:

PVDF coated aluminum coil is a favorably choice of material for high-quality aluminum curtain wall, aluminum veneer sheet, Honeycomb panel. Its products are widely used in airports, convention centers, hotels and other high-end architectural curtain wall decoration

Aluminum Plates

Aluminum coils / plates are widely used in building renovation (aluminum panels, honeycomb panels, aluminum veneer, tiles, ceiling, doors, windows, etc.), food packaging (such as bottle caps, lids). They can be used as cooling and temperature control material in electrical equipment.

- Q: Use of aluminium strips for aluminium strips

- 3003 plate strip. Foil. Thick plate, tensile tube. Extruded tube. Type. Bar. Wire rod。 Cold bar, cold wire, rivet wire, forging, foil, heat sink material mainly used for processing requires good molding property, high corrosion resistance, good weldability or parts, or both have these properties need than the workpiece of 1*** alloy with high strength, such as the transport of fluids tank and tank, pressure tank, storage device, heat exchanger, chemical equipment, aircraft fuel tank, oil pipe, reflective panels, kitchen equipment, cylinder washing machine, rivet, wire.5052 this alloy has good forming performance, corrosion resistance, fatigue strength, candle medium static strength, used in the manufacture of aircraft fuel tank, oil pipe, and the vehicle and vessel sheet metal parts, instruments, lights frame and rivet, metal products

- Q: What gas is best for welding aluminum strip?

- If you are using the gas, liquefied gas gun can be used separately burning liquefied petroleum gas welding, then burning gas is liquefied gas, but this time need to use low temperature welding wire, such as the WEWELDING M51 with WEWELDING M51-F solder welding wire.

- Q: Explain how aluminum strips can impact the waterproofing process and their role in construction.

- <p>Aluminum strips play a crucial role in waterproofing by serving as a barrier against water penetration. They are often used in construction to seal joints and seams where water could potentially infiltrate. These strips are durable, corrosion-resistant, and flexible, making them ideal for maintaining a watertight seal even under fluctuating temperatures and structural movements. They can be used in conjunction with other waterproofing materials such as sealants and membranes to create a robust defense against water damage. By preventing water from entering buildings or structures, aluminum strips help to protect against moisture-related issues like mold, structural decay, and deterioration, thereby enhancing the longevity and integrity of the construction.</p>

- Q: This question asks about the environmental effects of utilizing products made from recycled aluminum.

- <p>Using recycled aluminum products has several positive environmental impacts. It conserves natural resources by reducing the need for mining new aluminum, which is energy-intensive and can lead to habitat destruction. Recycling aluminum uses only 5% of the energy required to produce aluminum from raw materials, significantly reducing greenhouse gas emissions. Additionally, it decreases waste in landfills, as aluminum is infinitely recyclable without losing quality. This process also reduces water pollution and soil degradation associated with mining activities. Overall, the use of recycled aluminum products contributes to a more sustainable and environmentally friendly economy.</p>

- Q: Is it possible to construct an energy-efficient wall using aluminum strips compared to other materials?

- <p>Aluminum strips alone may not be the best choice for constructing an energy-efficient wall. Aluminum is a good conductor of heat, which means it can transfer heat quickly and isn't ideal for insulation. However, aluminum can be used in combination with insulating materials to enhance energy efficiency. For instance, aluminum composite panels with a core of insulation material can provide both structural strength and thermal insulation. The key to energy-efficient walls is to use materials with high R-values (thermal resistance), such as fiberglass, cellulose, or polyurethane foam. These materials, when combined with aluminum in a composite panel, can create a wall system that is both durable and energy-efficient.</p>

- Q: Is it possible to utilize aluminum strips in a construction project focused on sustainability and environmental responsibility?

- <p>Yes, you can use aluminum strips for a green building project. Aluminum is a versatile and sustainable material due to its recyclability and low energy consumption in production. It also has a high strength-to-weight ratio, which can contribute to the energy efficiency of a building. However, it's important to consider the source of the aluminum and ensure it is produced with minimal environmental impact. Using recycled aluminum can further enhance the green credentials of your project.</p>

- Q: Can metal roofing materials be reused or recycled after they have been installed and used?

- <p>Yes, metal roofing materials can indeed be recycled after installation. Metal is one of the most recycled materials globally, and its recycling process is both efficient and environmentally friendly. When metal roofing reaches the end of its life, it can be collected, processed, and turned into new metal products, including new roofing materials. This recycling process helps conserve natural resources and reduces waste in landfills. The high recycled content of metal can also contribute to the sustainability and green credentials of construction projects.</p>

- Q: Is it possible to use aluminum strips for decking purposes or for a neighbor's house?

- <p>Yes, you can use aluminum strips for your deck or your neighbor's house, provided it is for decorative or structural purposes approved by local building codes. Aluminum is known for its durability, resistance to corrosion, and low maintenance requirements, making it a popular choice for outdoor applications like decks. However, it's important to check with local regulations and consult with a professional to ensure the proper installation and use of aluminum strips to avoid any safety or legal issues.</p>

- Q: What is the minimum thickness that can be achieved when manufacturing an aluminum strip?

- <p>There is no absolute limit to how thin an aluminum strip can be made, but the practical limit is determined by the manufacturing process and the intended use of the strip. Modern technology allows for the production of aluminum strips as thin as a few micrometers. However, the thinness is constrained by factors such as material strength, ductility, and the specific application requirements. For instance, in the electronics industry, very thin aluminum strips are used for conductors, while in other applications, thicker strips might be necessary for structural integrity. The thinnest aluminum strips are often produced using techniques like rolling or extrusion, with the final thickness depending on the precision of these processes.</p>

- Q: Can the 6 square aluminum wires carry 3 pieces of air?

- Sure, the 3 air conditioners are less than 3 kilowatts. That's perfectly all right.

Send your message to us

Brushed Aluminum Trim Strips - Hot Sale Wooden Grain Color Coated Prepainted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords