Mill finished aluminium sheet wih high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Plain Aluminum Coil Sheet Description:

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. 3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment

2.Main Features of Plain Aluminum Coil Sheet :

Reasonable and stable chemical composition

Accurate tolerance

Nice mechanical property

Standards: EN, ASTM and EN

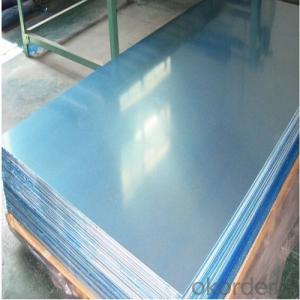

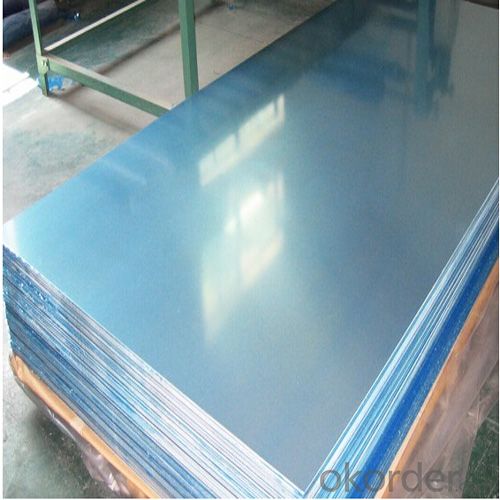

3.Plain Aluminum Coil Sheet Images:

4. Plain Aluminum Coil Sheet Specification:

| Description | Application | Feature | |

| 1000 SERIES | 1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. | Utensil, decoration, Reflecting plate, printing plate, heatproof plate,cookware | Easy to process and weld,resistant to rust,high,conductibility of electricity and heat,low strength |

| 3000 SERIES | 3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment | Utensil(F/P, inside of rice cooker), aluminum can,material for interior and exterior of building,chemical equipment,Cellular Phone | 20% higher strength than the 1100 series, easily welded and brazed, good antirust,ability Non-heat treatable |

| 5000 SERIES | 5xxx series representatives 5052 5005 5083,5754. The 5000 series aluminum alloy aluminum belong to the more commonly used series, the main elements for magnesium, with magnesium in the amount between 3-5%. And can be called aluminum magnesium alloy. Key features for low density, high tensile strength, elongation rate is high. In the same area under the weight of the magnesium alloy aluminum less than other series. | Ship board heatproof apparatus, material for interior and exterior of building, Parts of Electronic tools.Automobile Components | Excellent corrosion resistance andweld ability together with Easy to process and weld and superior hardness &heatproof Can be anodized for increased corrosion resistance |

| 6000 SERIES | 6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications. | IT equipment & facility, Mould material, motor material, automatic line, machine & plant etc | Easy to process , good corrosion resistance, high toughness and processed without distortion after heat-treatable, superior surface treatment |

| 7000 SERIES | 7000 aluminum alloy is another common alloy, wide variety. It contains zinc and magnesium. The best strength in the common aluminum alloy is 7075 alloy, but it can't be welded, and its corrosion resistance is rather poor, many manufacturing parts with CNC cutting is 7075 alloy. | The aerospace industry & High strength accessories | 7000 series is high tensile to process with special alloy |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: is general aluminum sheet fire-proof?

- general aluminum sheet is less fireproof than tinfoil.

- Q: What is the best way to paint over aluminium siding? Should it be primed? What type of prime should be used? What type of paint should be used on this surface? What brush or roller should be used to apply the paint?

- Two good answers above me, but I do want to add that aluminum siding will chalk on the outside. Definetely needs to be power washed, preferably with TSP (Tri Sodium Phosphate). That will get the metal totally clean to give it good tooth for the prime and paint. As said above, you need an aluminum prime, which is not a problem. Any paint store, Home Depot or Loews in the paint department can lead you to the right prime. Just make sure you are using the corresponding paint for your prime. Anyone can slap on a coat of paint, but when you do the groundwork first, you will have a paint job that will look like new for many years. I hope this helps you.

- Q: I'm trying to use as little aluminum as possible as it can be related to health problems, and I'm just trying to be a little more careful. I just bought the Emerilware pro-clad pot and pan set, and it's stainless steel but says Emerilware Pro-Clad is constructed with an aluminum core bonded between two layers of stainless steel ideal for... Therefore, I'm still cooking with aluminum. Is it safer since it's between 2 pieces of stainless steel? Does any stainless steel cookware not use aluminum? Thanks.

- First of all, there is no link between health problems and aluminum. Years ago, they thought there might be a link between alzheimer's and aluminum, but that has since been disproved. Secondly, stainless steel is a poor conductor of heat. But the stainless is a great, sturdy, non-reactive metal to use for cookware. So they add aluminum or copper to it's core to help it heat properly. Copper will cost you an arm and a leg, so all other cookware uses aluminum. If you had stainless cookware with no aluminum, it would take you an hour to boil water and your food would cook terribly unevenly. The outsides would burn before the inside cooked. So no, you won't find stainless without aluminum unless it's copper cored. But again, aluminum will do you no harm. You wrap your food in tin foil, which is aluminum. You eat food that has been sitting in aluminum cans on the shelf for god knows how long. And the anti-perspirant you use every morning? Check the ingrediants. Aluminum. Right on your lymph nodes. Stop worrying. Still worrying? aluminum is basically poreless. No aluminum will leach through. You are safe.

- Q: What types of aluminum sheets are recommended for outdoor applications?

- <p>Yes, there are specific types of aluminum sheets suitable for exterior use. These include aluminum sheets with a protective coating, such as anodized aluminum, which offers enhanced resistance to corrosion and weathering. Additionally, aluminum sheets with a Kynar 500庐 PVDF coating are highly resistant to UV rays, making them ideal for exterior applications. Marine-grade aluminum is also recommended for exterior use due to its superior corrosion resistance, especially in coastal areas. These types of aluminum sheets are designed to withstand harsh outdoor conditions and maintain their integrity over time.</p>

- Q: Is it possible to use aluminum sheets as a material for interior walls?

- <p>Yes, aluminum sheets can be used for interior walls. They are known for their durability, resistance to corrosion, and ease of maintenance. Aluminum sheets can also be painted or finished in various ways to match different interior design styles. They are lightweight, which makes them easy to install, and they provide good thermal insulation. However, it's important to consider the acoustic properties and the need for proper insulation to prevent condensation, especially in colder climates.</p>

- Q: Other then pop cans, what else is aluminum that can be recycled?

- Anything made of aluminum can be recycled. Aluminum cans are just a visible item that can be used for social engineering purposes. The cans also are very pure form of the metal. You will find aluminum in many things, from parts in your computer, major parts in your family car, pots, pans, kitchen items, tools, display items, structural supports for various things, boats, canoes, airplanes, and the list is long. Fact is, it would be difficult to find many items where aluminum was NOT used. Although everything that is metal that a magnet would not stick to, is not always aluminum. ANY metal can be recycled, and most metals can be sorted for recycling when you find a recycling plant that will buy the materials. Some of the metals need to be in large quantity, or weight in order to be worthwhile sorting. Some things like batteries can be sorted by general type. Some of those are easier to break down to component metals than others. Some have hazardous substances in them so need care in storage, and some have hazardous substances that need special care in shipping them. But they are exception.

- Q: I have tried every possible method that I could find on the web for cleaning aluminum, tungsten, filler wire. Nothing has seemed to work. I've tried looking for leaks in the argon line. I'm getting decent welds but there is gunk in the welds for sure. I'm worried about overall strength of the welds. Does anybody out there know of a tried and true method for cleaning aluminum, tungsten, filler etc. that is sure to work? If I can follow that method and still have problems It could possibly be a problem with the machine. Any help would be much appreciated.

- Preweld cleaning requires two operations: oil/grease removal and oxide removal. As below, remove oils and greases first, then remove the oxide. Don’t reverse this order. Take the following steps before welding aluminum: 1. Remove oil, grease, and water vapor using an organic solvent such as acetone or a mild alkaline solution like a strong soap. You may also use citrus-based degreasers, but be sure to rinse and dry the part before welding. 2. Remove surface oxides with a stainless steel wire brush (used only for aluminum) or strong alkaline or acid. Many welding suppliers sell oxide-removal solutions in spray or squeeze bottles for local application. Exercise extreme care when handling these solutions, and again, rinse and dry the part before welding. 3. Assemble the joint. If it won't be welded immediately, cover the joint with brown Kraft paper to prevent dirt and grit in the air from getting into the joint. 4. Keep the aluminum dry and at room temperature. 5. Weld within a few days. Clean the joint again if it isn't welded within that time. Good luck!!!

- Q: This question asks for methods to protect aluminum sheets from damage during the installation process.

- <p>To prevent damage to your aluminum sheets during installation, follow these steps: Use protective gloves to avoid scratches from hand contact. Handle the sheets with care, especially at the edges and corners. Keep the surface clean and dry to prevent any dirt or moisture that could cause damage. Use appropriate tools designed for aluminum to avoid marring the surface. Ensure the installation site is free from debris that could cause scratches or dents. Install the sheets in a controlled environment to avoid exposure to harsh weather conditions. Finally, consider using a protective film or cover on the aluminum sheets until they are fully installed.</p>

- Q: What are the different types of aluminum sheets available?

- There is a variety of aluminum sheets available, each with its own distinct properties and uses. Some of the most commonly used types are as follows: 1. Pure Aluminum Sheets: These sheets are composed entirely of aluminum and are known for their exceptional resistance to corrosion and high thermal conductivity. They are frequently employed in industries where lightweight and durability are crucial, such as aerospace. 2. Aluminum Alloy Sheets: These sheets are produced by combining aluminum with other elements like magnesium, copper, or zinc, in order to enhance specific properties. For instance, aluminum-magnesium alloy sheets (5000 series) possess remarkable strength and corrosion resistance, making them suitable for marine applications. 3. Painted Aluminum Sheets: These sheets are coated with paint or a protective layer, providing additional defense against corrosion and enhancing their visual appeal. They are commonly utilized in architectural projects and signage. 4. Perforated Aluminum Sheets: These sheets are characterized by evenly spaced small holes or perforations across their surface. They are frequently used in situations where airflow or visibility is required, such as HVAC systems, decorative panels, or speaker grilles. 5. Embossed Aluminum Sheets: These sheets feature a raised pattern or design on their surface, achieved through the process of embossing. This not only adds visual interest but also increases the sheet's strength, making it suitable for flooring, vehicle panels, or decorative purposes. 6. Anodized Aluminum Sheets: This type of aluminum sheet undergoes an electrolytic process known as anodizing, which creates a protective layer on the surface. Anodized sheets exhibit high resistance to corrosion and wear, making them ideal for outdoor applications like building facades, window frames, or automotive trim. Before selecting an aluminum sheet, it is crucial to consider the specific requirements of your project. Factors such as strength, corrosion resistance, appearance, and cost should be taken into account to ensure the most appropriate sheet is chosen for the job.

- Q: (2) when aluminium foil is dipped in mercury for a short time and then placed in water a reaction is seen to occur with hydrogen gas being one of the products.?????

- Aluminium is very reactive in air and forms a protective oxide coating. This protects it when placed in water as aluminium oxide is unreactive with water. When immersed in mercury the oxide coating is removed and therefore the aluminium itself reacts when the cleaned aluminium metal is immersed in water.

Send your message to us

Mill finished aluminium sheet wih high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords