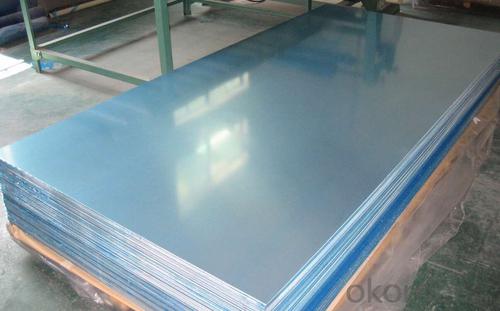

Mill Finished Aluminum Sheets 3xxx - Rolled Aluminum Sheets for Roofing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1000 series aluminum sheet is a commercially pure aluminum.

Excellent welding characteristics

Excellent ductile property

Excellent resistance to corrosion

Excellent conductivity

Application of 1000 series aluminum sheet

Chemical and food processing industries

Eye-appeal necessity needed material

Curtain wall material

Cookware material

Nameplate material

Decorative and reflective material

3000 series aluminum sheet is a commercially pure aluminum with the addition of manganese.

Good corrosion resistance

Excellent weldability,formability

Good corrosion resistance

Moderate strength

Specially, 3104 aluminum alloy is a typical deep-drawing material.

Application of 3000 series aluminum sheet

Food & Chemical processing and storage container

Deep drawing processing material

5000 series Aluminum Sheet is a typical Al-Mg aluminum product.

High stength

Good salt water resistance

Good low temperature ressistance

Application 5000 series Aluminum Sheet :

8000 series aluminum sheet for foil material

- Q: What is the cost of aluminum sheet compared to other metals?

- The price of aluminum sheet can differ from other metals depending on various factors like market conditions, availability, and specific metal grades. Generally, aluminum sheet is considered more economical than stainless steel, copper, and brass, among others. This is primarily because aluminum is abundant in the Earth's crust and the extraction and refining processes are relatively inexpensive. In addition, aluminum is often lighter in weight compared to other metals, making it a cost-effective choice for industries where weight is a concern, such as transportation. However, it should be noted that the cost of aluminum can change due to global supply and demand, tariffs, and other economic factors. Therefore, it is advisable to check current market prices and consult with suppliers or metal experts for accurate and up-to-date pricing information.

- Q: Can the aluminum sheets be used for manufacturing automotive wheels?

- Yes, aluminum sheets can be used for manufacturing automotive wheels. Aluminum is a lightweight and durable material that is commonly used in the automotive industry due to its high strength-to-weight ratio. Aluminum sheets can be formed and machined into the desired shape and specifications required for automotive wheels. Additionally, aluminum has excellent corrosion resistance properties, which is beneficial for automotive wheels that are exposed to various weather conditions and road debris. Overall, aluminum sheets are a suitable material for manufacturing automotive wheels, providing a balance of strength, weight, and corrosion resistance.

- Q: For example, now the price of aluminum is 30000 yuan / ton. How much is that 2mm aluminum sheet with 1 square meters? What's the formula?What about the stainless steel plate, iron plate, and galvanized sheet? Can these (yuan / ton) be converted into (yuan / square)?Hurry! Which expert can I help you?!

- Know that the density of aluminum is 2.7 g / cubic centimeter or 2700 kg / cubic meterThen 2mm thick aluminium plate with a weight of 1 square meters is:M= P *v=2700*1*0.002=5.4 (kg)=5.4*10^ (-3) tonsThe price of aluminium is 30000 yuan / ton nowTherefore, the title of the money required should be 30000* (5.4*10^ (-3)) =162 yuanEmpathy,The density of iron is 7.8 KG/M3The density of stainless steel is 7.52-7.75 KG/M3The same is true of galvanized sheets, as long as the density is known

- Q: Is aluminium plate the same as aluminium alloy?

- In fact, it means that the world can not meet the so-called aluminum plate, that is, pure aluminum alloy is only a little more than pure aluminum alloy, but the scope of the use is also different

- Q: Is it possible to use adhesive instead of fasteners to bond aluminum sheets to a structure?

- <p>Yes, you can use an adhesive to attach aluminum sheets to a structure. However, it's important to choose an adhesive that is specifically designed for bonding aluminum, as not all adhesives provide the necessary strength and durability. Structural adhesives that are compatible with aluminum can offer a strong bond and are often used in applications where a clean, seamless appearance is desired or where fasteners are not suitable. It's crucial to ensure that the adhesive is resistant to the environmental conditions the structure will be exposed to, such as moisture, temperature fluctuations, and UV radiation. Always follow the manufacturer's instructions for surface preparation and application to achieve the best results.</p>

- Q: Are aluminum sheets suitable for electrical connectors?

- Yes, aluminum sheets are suitable for electrical connectors due to their excellent electrical conductivity and corrosion resistance.

- Q: What's the price of the 6mm aluminum sheet?

- The single aluminum plate is aluminum substrate, around the hem (can be customized size and shape) and install bracket forming a mounting edge, the surface of the fluorocarbon coating (various colors can be customized). Aluminum single board, white meters, Beijing reference price of 320 yuan / square meter, specific to take into account your size, material requirements, plate type and so on, generally see drawings quote.

- Q: What are the different types of alloys used in aluminum sheet?

- There are several different types of alloys used in aluminum sheet. Some of the most commonly used alloys include: 1. 3003 alloy: This alloy is known for its excellent resistance to corrosion and is often used in applications where exposure to moisture is a concern. It is also easy to form and weld, making it a popular choice for various structural components. 2. 5052 alloy: This alloy is highly corrosion-resistant and has good formability. It is often used in marine and automotive applications, as well as in architectural elements. 3. 6061 alloy: This alloy offers excellent strength and is commonly used in applications that require high structural integrity. It is often used in aerospace and marine industries, as well as in the construction of heavy-duty machinery. 4. 7075 alloy: This alloy is known for its high strength-to-weight ratio and is often used in aerospace and defense applications. It is also used in the manufacturing of bicycle frames, rock climbing equipment, and other high-performance applications. 5. 2024 alloy: This alloy is known for its high strength and excellent fatigue resistance. It is often used in aerospace applications, as well as in the production of structural components and fasteners. These are just a few examples of the many different types of alloys used in aluminum sheet. Each alloy has its own unique properties and advantages, making it suitable for specific applications and industries.

- Q: What specific tools or equipment are required when working with aluminum sheets?

- <p>When working with aluminum sheets, you'll need a few special tools and equipment. These include sheet metal shears for cutting, a metal file for smoothing edges, a metal straight edge for measuring and marking, and a vise for holding the sheet securely. For bending, a sheet metal brake is essential. Safety gear such as gloves and goggles are also crucial to protect against sharp edges and debris. Additionally, a T-square and a marker are needed for precise measurements and markings.</p>

- Q: Can aluminum sheets be used for electrical enclosures?

- Yes, aluminum sheets can be used for electrical enclosures. Aluminum is a popular choice for electrical enclosures due to its excellent conductivity, corrosion resistance, and lightweight properties. It is a good conductor of electricity, allowing for efficient distribution of electrical current within the enclosure. Additionally, aluminum has a high resistance to corrosion, making it suitable for outdoor and harsh environment applications. Its lightweight nature also makes it easier to handle and install. Overall, aluminum sheets are a reliable and commonly used material for electrical enclosures.

Send your message to us

Mill Finished Aluminum Sheets 3xxx - Rolled Aluminum Sheets for Roofing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords