Coil Coated Aluminum Plate - Mill Finish Aluminum Coil in Rolls 1000 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum Coil in Rolls 1000 Serie

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of Mill Finish Aluminum Coil in Rolls 1000 Serie

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Coil in Rolls 1000 Serie

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

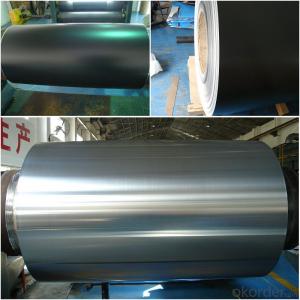

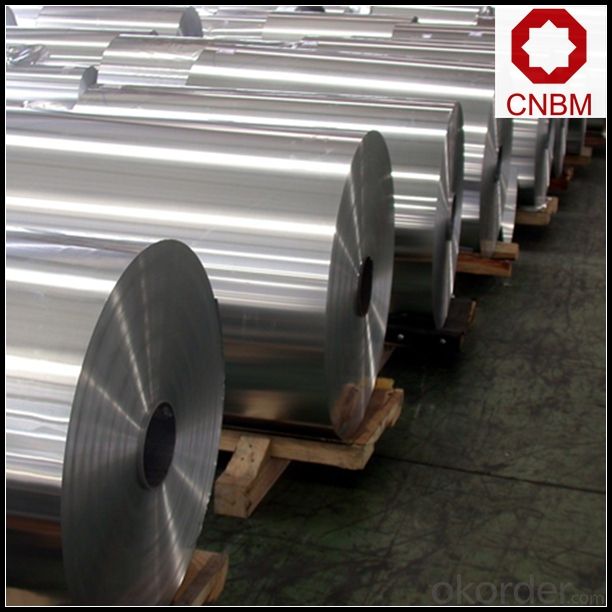

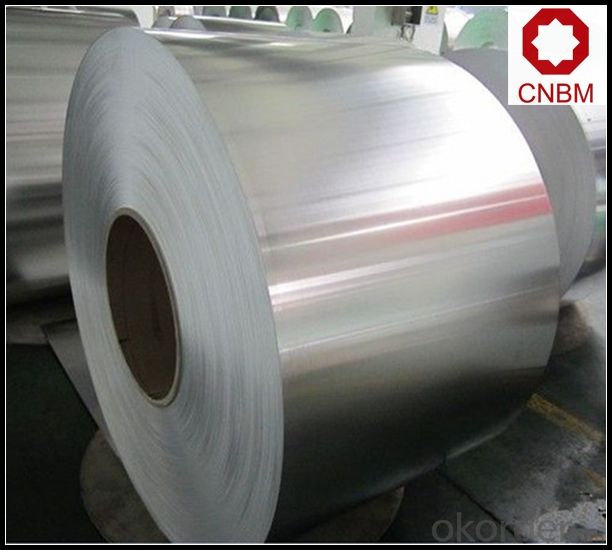

5. Image of Mill Finish Aluminum Coil in Rolls 1000 Serie

6. Package and shipping of Mill Finish Aluminum Coil in Rolls 1000 Serie

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Why is the aluminum roll upset?

- Mainly in the aluminum slitting process, for various reasons, does not meet the standards and specifications of products, can be used to roll the machine from the new trimming and slitting, winding up to meet customer needs of product specifications

- Q: Are aluminum coils suitable for marine environments?

- Due to their excellent corrosion resistance properties, aluminum coils are well-suited for use in marine environments. One of the reasons for this is that aluminum naturally develops an oxide layer on its surface, which acts as a protective barrier against saltwater corrosion. Consequently, aluminum coils demonstrate a high level of resistance to rust and deterioration caused by exposure to marine conditions. Furthermore, the lightweight nature of aluminum makes it an ideal choice for marine applications where reducing weight is crucial. Moreover, aluminum coils possess good thermal conductivity, which is advantageous for dissipating heat in marine cooling systems. All in all, aluminum coils are a dependable and durable option for marine environments, guaranteeing long-lasting performance and minimal maintenance needs.

- Q: I have a broken exhaust stud in my engine head. I have an aluminum head but the stud is steel. The stud broke a little below the surface. I want to mig weld a washer to the stud, but will the weld stick to the aluminum or will it blow a big hole in the head? I will only be using a little 110 mig welder.will I be okay or will that lead to more problems?

- It will blow a big hole in it if you touch it with the arc. Drill a hole in it sized for an easy out. Use that to unscrew it. Go to an auto parts store or good hardware store. They will know what an easy-out is. Make sure you don't drill the hole too big and it must be centered or you will damage the threads. If that happens you can drill it out bigger and get a thread insert, but that will be harder for you to find.

- Q: This question asks about the common applications of aluminum coil in everyday life.

- <p>Aluminum coil is widely used in daily life due to its lightweight, corrosion resistance, and thermal conductivity. It's commonly used in construction for roofing and siding, in the automotive industry for car parts, and in the packaging industry for food and beverage cans. It's also used in electrical applications like transformers and wiring due to its good conductivity. In the kitchen, aluminum foil is used for cooking and food storage, and in the HVAC industry for heat exchangers and ductwork. Its versatility makes aluminum coil an essential material in many industries and everyday applications.</p>

- Q: Are aluminum coils suitable for food processing applications?

- Food processing applications can benefit from the use of aluminum coils. Aluminum is a versatile material widely utilized in the food industry for its advantageous properties. It is resistant to corrosion, non-toxic, lightweight, and possesses exceptional thermal conductivity. These qualities make aluminum coils perfect for various food processing tasks like cooking, storage, and transportation. Aluminum coils find their application in the production of cookware, food packaging, and food processing equipment. They are frequently employed in the manufacturing of kitchen utensils such as pots, pans, baking sheets, and more. The remarkable thermal conductivity of aluminum ensures uniform distribution of heat, enabling efficient cooking and eliminating hot spots. Moreover, aluminum coils are commonly utilized in food packaging, including beverage cans and canned foods. Aluminum cans are lightweight, durable, and provide a protective barrier against light, moisture, and air, thus preserving the quality and freshness of the food products. Additionally, aluminum coils are suitable for food processing equipment like heat exchangers, evaporators, and refrigeration systems. The corrosion-resistant nature of aluminum prevents contamination, thereby ensuring the hygiene and safety of the processed food. It is crucial to note that aluminum coils utilized in food processing applications must meet specific food-grade standards to ensure they do not release any harmful substances into the food. These standards are set by regulatory bodies like the Food and Drug Administration (FDA) in the United States and similar organizations globally. Overall, due to their corrosion resistance, non-toxicity, lightweight, and excellent thermal conductivity, aluminum coils are highly suitable for food processing applications. Their extensive usage in the food industry for cooking, packaging, and processing equipment significantly contributes to the safety and efficiency of food production.

- Q: What house hold materials contain 100% pure aluminum. or where can i buy it. im making thermite, which ive made before so don't say, its dangerous don't do it, but do i need 100% pure aluminum or will some aluminum alloy with like 90% aluminum work?????

- Aluminum foil is your best bet. According the the Reynold's wrap web site, their foil is 98.5% aluminum.

- Q: Can aluminum coils be used in outdoor applications?

- Indeed, outdoor applications can make use of aluminum coils. Given its remarkable resistance to corrosion, aluminum proves to be an appropriate material for outdoor purposes. It finds frequent employment within the construction sector for various outdoor structures, including roofs, gutters, and siding. Moreover, the lightweight and manageable nature of aluminum coils contribute to their widespread preference in outdoor applications. Nevertheless, it is crucial to bear in mind that the particular grade and thickness of the aluminum coil must be carefully evaluated to ensure its endurance against the environmental conditions unique to the specific outdoor application.

- Q: Can aluminum coils be used in the production of aircraft fuel tanks?

- Aluminum coils, with their lightweight and durable nature, find application in the creation of aircraft fuel tanks. They are commonly employed in the aerospace industry due to their impressive strength-to-weight ratio. Furthermore, their corrosion-resistant properties make them an ideal choice for fuel tanks, as they can withstand the harsh conditions and chemicals present in aviation fuel. The utilization of aluminum coils enables efficient manufacturing processes, as they can be easily shaped and welded into the desired tank form. Moreover, aluminum possesses excellent thermal conductivity, aiding in the dissipation of heat generated during flight and preventing fuel overheating. In conclusion, aluminum coils are a fitting and extensively utilized material in the production of aircraft fuel tanks.

- Q: Is it possible to utilize a magnetic stirrer to determine the magnetic characteristics of an aluminum coil?

- <p>No, you cannot use a magnetic stirrer to test the magnetic properties of an aluminum coil. Aluminum is a non-magnetic material, meaning it does not respond to magnetic fields in the way magnetic materials like iron, nickel, or cobalt do. A magnetic stirrer operates by creating a rotating magnetic field to stir substances, but since aluminum is non-magnetic, it will not be affected by the stirrer's field. To test magnetic properties, you would need to use materials that are ferromagnetic or paramagnetic, or employ other methods such as a magnetometer for measuring magnetic fields.</p>

- Q: Are there any limitations to using aluminum coils?

- Yes, there are several limitations to using aluminum coils. Firstly, aluminum coils are more expensive compared to other coil materials such as copper. This can be a limiting factor for individuals or businesses with budget constraints. Secondly, aluminum coils have lower thermal conductivity than copper coils. This means that they are less efficient at transferring heat, which can result in decreased performance in some applications. Additionally, aluminum is more susceptible to corrosion and oxidation compared to other materials. This can be a limitation in environments that are highly corrosive, such as coastal areas or industrial settings. Furthermore, aluminum coils are generally not suitable for high-pressure applications. They are more prone to leaks or failures under high pressure, which can limit their use in certain HVAC systems or refrigeration units. Lastly, aluminum coils are not as malleable as copper coils, making them more difficult to work with during installation or repair. This can lead to increased labor costs or potential damage to the coils during handling. Overall, while aluminum coils have their advantages such as being lightweight and environmentally friendly, they also have limitations that need to be considered based on the specific application and requirements.

Send your message to us

Coil Coated Aluminum Plate - Mill Finish Aluminum Coil in Rolls 1000 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords