Alsco Aluminum Coil - Mill Finished Aluminum Coils Hot Rolled AA1100

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

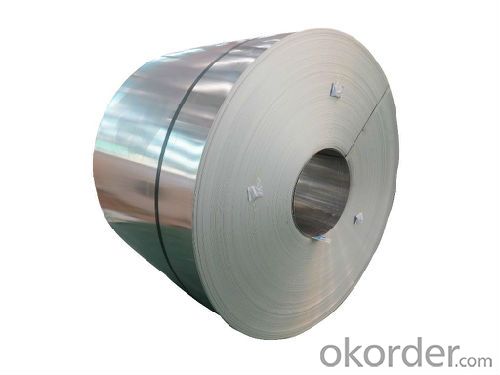

1.Structure of Mill finished Aluminium Coils Description

Mill Finished Aluminium Strip in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1100 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Mill Finished Aluminium Coils

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Products Specification

| Alloy | Temper | Thickness Tolerance | Coil Package | Coil OD |

| AA1100 | H18 | 0.02MM | Eye to sky | 1500mm |

5.FAQ

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What are the different edge profiles available for aluminum coils?

- Aluminum coils offer various edge profiles to cater to specific needs and preferences. The options include: 1. Square Edge: This simple profile has sharp corners and a flat surface, often used in functional industrial applications. 2. Round Edge: With a curved surface that eliminates sharp corners, this profile ensures safety and is commonly used in automotive and playground equipment. 3. Beveled Edge: This profile boasts a sleek and modern look with its slanted or angled surface, making it popular for architectural purposes and reducing the risk of injuries. 4. Full Radius Edge: Featuring a smooth, rounded surface along the entire coil length, this profile minimizes the risk of damage or scratching when in contact with other materials. 5. Hemmed Edge: By folding the edge back onto itself, this profile creates a double layer of metal, providing a strong and durable edge for appliances and cabinets. 6. Tapered Edge: Gradually narrowing the coil's width towards the edge, this profile adds visual interest and a dynamic appearance, often chosen for architectural or decorative purposes. It's important to consider that the availability of these edge profiles may vary among manufacturers and depend on the intended application. Consulting with the supplier or manufacturer is recommended to determine the specific edge profiles available for a particular coil.

- Q: Are there any specific regulations for the disposal of aluminum coil waste?

- Yes, there are specific regulations for the disposal of aluminum coil waste. The disposal of aluminum coil waste is subject to various environmental regulations to ensure proper handling and prevent any potential harm to the environment and human health. One of the key regulations is the Resource Conservation and Recovery Act (RCRA) in the United States. Under this act, aluminum coil waste is considered a hazardous waste if it exhibits certain characteristics such as ignitability, corrosivity, reactivity, or toxicity. If the waste meets these criteria, it must be managed as hazardous waste and disposed of in accordance with RCRA regulations. This may involve treatment, storage, and disposal at an approved hazardous waste facility. Additionally, the Environmental Protection Agency (EPA) has established guidelines for the disposal of non-hazardous aluminum coil waste. These guidelines typically require proper storage, labeling, and transportation of the waste to an authorized disposal facility. The disposal facility should be equipped to handle and process the waste in an environmentally responsible manner. In many countries, including the United States, local, state, and federal regulations may also apply to the disposal of aluminum coil waste. These regulations may vary depending on the specific location and the nature of the waste. It is crucial for businesses and individuals involved in the disposal of aluminum coil waste to familiarize themselves with the applicable regulations to ensure compliance and avoid potential penalties. Overall, it is important to follow the specific regulations for the disposal of aluminum coil waste to protect the environment, prevent pollution, and ensure the safety of individuals involved in waste management.

- Q: How do aluminum coils contribute to sustainable construction?

- Due to their numerous environmental benefits, aluminum coils play a vital role in promoting sustainable construction practices. One key advantage is the high recyclability of aluminum, with almost 75% of all aluminum ever produced still in use today. This means that at the end of their lifespan, aluminum coils can be easily recycled, reducing the need for new raw materials and minimizing waste sent to landfills. Furthermore, compared to other materials like steel, the production process of aluminum coils requires significantly less energy. This results in a low carbon footprint, as the energy consumed during production is considerably lower, leading to fewer greenhouse gas emissions. Additionally, the reduced energy consumption contributes to lower operating costs for construction projects, making aluminum coils an economically viable choice. Moreover, aluminum coils are not only lightweight but also highly durable, making them an ideal option for sustainable construction. Their lightweight nature reduces the need for heavy support structures, which in turn reduces material consumption and transportation costs. Additionally, the durability of aluminum coils ensures a longer lifespan, reducing the frequency of replacement and minimizing waste generation. Another crucial aspect of aluminum coils in sustainable construction is their excellent corrosion resistance. This resistance means that structures made from aluminum coils require less maintenance and repair over time. Consequently, fewer resources are needed to uphold the building's integrity, resulting in a reduced overall environmental impact. In conclusion, aluminum coils contribute significantly to sustainable construction through their high recyclability, energy efficiency, lightweight yet durable nature, and excellent corrosion resistance. By opting for aluminum coils, construction projects can significantly decrease their environmental footprint, conserve resources, and advocate for a more sustainable built environment.

- Q: What industries utilize aluminum coils?

- There are several industries that utilize aluminum coils for various purposes. One of the major industries that extensively uses aluminum coils is the construction industry. Aluminum coils are commonly used for roofing, siding, and gutter systems due to their lightweight nature, durability, and resistance to corrosion. Additionally, the transportation industry also relies heavily on aluminum coils for manufacturing automotive parts, such as radiators, condensers, and heat exchangers, as aluminum is known for its excellent heat transfer properties. The packaging industry also utilizes aluminum coils for producing cans and containers due to their ability to preserve the freshness and quality of food and beverages. Moreover, the electrical industry relies on aluminum coils for manufacturing transformers, electrical conductors, and wiring, as aluminum is a good conductor of electricity. Lastly, the aerospace industry uses aluminum coils for constructing aircraft parts, such as wings, fuselage, and structural components, as aluminum provides strength while keeping the weight of the aircraft low.

- Q: Can aluminum coils be used in the production of cryogenic storage tanks?

- Yes, aluminum coils can be used in the production of cryogenic storage tanks.

- Q: How heavy and long is the aluminum rolling on average?

- On average it is 5 or 6 tons, and you can weigh specific ones. The length = weight/(width*thickness*density).

- Q: What can I get easily at Home Depot that will successfully bond rubber to aluminum?? I have tried several things with no success! Surely, there must be some sort of construction adhesive to do the job.Thanks!

- Gorilla Glue. I'd rough-up both the rubber and aluminum with course-grit sandpaper, or a wood-rasp first. Generally though, rubber is molded in place or fastened with a mechanical fastener (Screw, bolt, rivet, etc).

- Q: What are the different coil handling methods for aluminum coils?

- There are several coil handling methods for aluminum coils, including manual handling, fork truck handling, coil grabs, and coil tongs. Manual handling involves physically lifting and moving the coils by hand, while fork truck handling utilizes a forklift to transport and position the coils. Coil grabs and coil tongs are specialized tools that can be attached to lifting equipment to securely grip and lift the coils. These methods ensure safe and efficient handling of aluminum coils in various industrial settings.

- Q: Im doing an assignment for science and i need to know the nuclear charge of Aluminium?and also is there a difference between Aluminium and Aluminum or can it just be spelt differently?

- ALUMINIUM ALUMINUM ARE ONE SAME ELEMENT . the nuclear charge means number of protons . the number of protons electrons are ALWAYS equal = 13 e- = p

- Q: What are the weight considerations when using aluminum coils?

- When using aluminum coils, weight considerations primarily involve the overall weight of the coils themselves and the impact it may have on transportation, installation, and structural support systems. Aluminum coils are preferred in various industries due to their lightweight nature, which enables easier handling and reduces the load on infrastructure. However, it is important to ensure that the weight of the coils aligns with the intended application and the capacity of the supporting structures. Additionally, factors such as coil thickness, width, and length should also be taken into account to determine the appropriate weight considerations when using aluminum coils.

Send your message to us

Alsco Aluminum Coil - Mill Finished Aluminum Coils Hot Rolled AA1100

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords