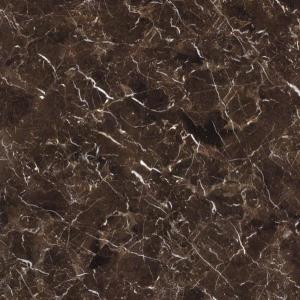

Microcrystalline Glass

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Microcrystalline Glass(Glass-ceramics) are polycrystalline material produced through controlled crystallization of base glass.

- Q: Do solar panels use toughened glass, or are some high light transmitting materials good?

- Ultra white glass raw materials imported or made of iron high transmittance (transmission rate of up to 92%), through tempering (heating quenching), so that the strength of the glass increased 3--5 times, broken glass debris particle degree of safety, no harm to human body. The thickness of 2MM, 3MM, 3.2MM 4MM, etc..

- Q: Acrylic plexiglass rod can be used in what way?

- Adhesive: two components. One component and two components, such as adhesive and epoxy resin; one component, such as CCl3 (Lv Fang). A two-component adhesive through curing reaction to achieve bonding, one component adhesive is a volatile solvent and finally realize bonding. The two component adhesive is characterized by good bonding effect, no bubbles, no white and strong strength after bonding.

- Q: How to seal the glass fiber reinforced plastic mould?

- Rubber pad seals are thickness, will be relatively increased parting surface gap, for complex, not good concave convex surface, uneven surface, you can use ordinary fastening before playing glass glue or fastening hot melt gun hit again. It can be divided into surface on floor wax coat material brush, then fastening glass steel mold.

- Q: What kind of material is the toughened glass film made of mobile phone?

- The low iron glass toughened ultra white suede;To enhance transmittance, a layer of antireflective coating is also applied to the front of the glass

- Q: Does anyone know iPhone's toughened glass production process? Thank you

- The first special glass raw materials used for Corelle Corning, Gorilla Glass or AGC Dragontrail Glass (Asahi; if you need a AR antireflection coating processing, processing)

- Q: Aluminum alloy window material is good, how to assemble?

- Sealing material: according to its different material, can be divided into structural sealant, building sealant (weather glue) and insulating glass two sealant. Structural sealant can be divided into one component and two components, two kinds. One component sealant, acid sealant and neutral sealant and so on. According to the method of fixing and fixing glass, the sealing material is divided into two kinds: dry material and wet material. When in use, the utility model can be used both inside and outside of the dry material, and can also be used for both inside and outside, and can be used in a mixed way. That is to say, when the outer side of the glass is arranged, the inner part of the glass is dry, and the outer part of the wet material or the inner side of the glass is provided with wet material for external use and dry. Dry material is finished product (market), according to its aluminum alloy notch in the form of different and divided into several kinds, soft and hard degrees are also different.

- Q: Tempered and reinforced glass

- Enterprises producing safety glass must pass compulsory certification by the state, otherwise they are not allowed to appear on the market. Therefore, toughened glass has the following signs:Tempered glass, if made into reinforced glass, is substandard products.10mm toughened glass generally costs less than 100 yuan. Paint and not much money, but if the price is higher glaze.

- Q: What's the difference between three kinds of glass fiber board, epoxy board and FR4 board?

- Glass fiber board, also known as glass fiber board, commonly used in soft base cloth, leather bag, outside, a beautiful wall and ceiling decoration. Very wide range of applications. It has the characteristics of sound absorption, sound insulation, heat insulation, environmental protection and flame retardance.FR-4 also known as the glass fiber; glass fiber board; FR4 reinforcing plate; FR-4 epoxy resin board; flame retardant insulation board; epoxy plate, FR4 plate; glass board; PCB drilling pad.

- Q: Which is the best solar water heater tube?

- There are three kinds of vacuum heat collecting tubes: high temperature pipe, high efficiency pipe and high cold pipe. High temperature pipe coating than ordinary length (from the nozzle is about 1cm), the tube of high temperature resistance, anti damping performance is particularly strong, the film on the 400 DEG C high temperature air drying condition, not aging, not falling, not color. The high efficiency pipe film is about 2.5cm apart from the pipe mouth. The tube is ultra high absorption, less heat loss, fast heating up and high thermal efficiency. The high temperature pipe has the advantages of high efficiency, high heat efficiency and fast heating, less heat loss, and hot water as usual under the condition of 30 DEG C. Consumers can choose different vacuum heat collecting tubes according to different areas.

- Q: What kinds of ingredients are the glass?

- Is usually made of sand, sodium carbonate and calcium carbonate eutectic is prepared; also available mixture of sodium sulfate and sodium carbonate to replace carbon melting. Some other glass such as potassium glass, is a relatively high temperature, hard and chemical resistance of glass in molten glass with potassium carbonate to replace sodium or potassium sulfate prepared, mainly used in chemical container manufacturing laboratory commonly used.

We manufacture high-tech products, mainly including transparent glass ceramic, black ceramic glass, porcelain white glass ceramic, ceramic containers and so on. Our products are mainly applicable for electric furnaces, induction cookers, highlight cookers, electric ceramic heaters, microwave ovens, ovens, physiotherapy instruments, gas stoves, cooking utensils, fireplaces, observation windows and so on.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe |

| Company Certifications | ISO 9001:2000 ;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Ningbo, Shanghai |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 50,000-100,000 square meters |

| No. of Production Lines | 7 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Low |

Send your message to us

Microcrystalline Glass

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords