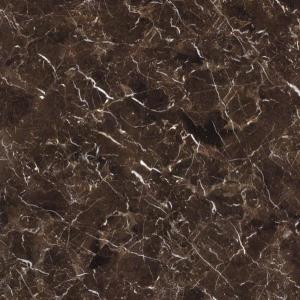

Microcrystalline Glass-7

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Microcrystalline Glass(Glass-ceramics) are polycrystalline material produced through controlled crystallization of base glass.

- Q: What is the raw material for making glass?

- The 60% component of the crystal is "two oxide" (SiO2). The color of the crystal is due to the addition of two silicon oxide, which also contains a variety of trace metals. In the natural environment, and most of crystal mineral calcite, pyrite, iron ore, Hui various colors of mica, Biqian, granite, Jin Hongshi and other "symbiosis", and formed some suspected imaginary scene, the so-called "different" like crystal, crystal increased collection of fun and value.

- Q: What are the anticorrosive materials for glass fiber reinforced plastic?

- The specific construction program for the three cloth five oil, namely the bottom coating again after solidification and then brush a layer of epoxy glass cloth, coating, a layer of glass cloth again, painted again, then brush a layer of glass cloth epoxy cover can be again.

- Q: There are several appearances of the quality defects of ordinary flat glass

- There in the flat glass some prominent particles, called big lump or small stones, called sand. It mainly affects the optical properties of glass and makes it difficult to cut glass.

- Q: Aluminum alloy window glass tape, how fast loading?

- The above two methods can only use single material, that is dry material or wet material. If the wet material is used, the first side is fixed and the other side is injected with glue and then injected onto the side. Both the inner mounting method and the outboard mounting method are best for both sides using wet material. The watertight and air tightness and the best effect of glial sickness, it is best to use silicone sealant for good. For ordinary simple aluminum alloy doors and windows, the use of single glass, fixed glass, both inside and outside the use of dry materials. For the Aluminum Alloy windows advanced commonly used sandwich or hollow glass, glass raw materials used by the heat absorbing glass processing or colored glass, glass were used for fixing the wet material or mixed material.

- Q: Glass raw materials, in addition to quartz sand, what else can be the main raw materials?

- Glass raw materials are: soda ash, limestone, quartz, the ratio is: 1:1:6

- Q: Which brand of thermos cup is safe, double glass is not really glass, there is no other add, affect health?

- Double glass also called light industrial glass, raw materials for high boron silicon has a high heat resistance, the main production of glass teapot, coffee cup, cup, cup of hot water, there are many domestic manufacturers.

- Q: The practice of acid corrosion in tank

- Excellent technical performance, it can meet the corrosion protection requirements in the corrosive environment. Technical indexes are formulated for different coating varieties and matching. Such as chemical resistance medium, salt water resistance, salt fog resistance, heat and humidity resistance, oil resistance, mildew resistance, atmospheric aging, etc.. In addition, heavy duty coating has good adhesion to metal substrate. The coating has good physical and mechanical properties, such as low shrinkage, proper hardness, toughness, wear resistance and temperature resistance.

- Q: What's the difference between crystal and ordinary glass?

- To strike lightly or with fingers. Crystal glass can produce metal crisp sound, and waves a beautiful lingering in the air. We will see at the reception banquet, high-end glasses scenes in the movie, a kind of glass between the collision sound is. And high school, low grade crystal glass sound is also different. Like some low-end crystal glass or ordinary glass voice is relatively boring.

- Q: What kind of raw material does glass form? What is the general smelting process?

- Before people made of glass which has a lot of people use a lot of bubbles, there is no way to take out that European countries made out of glass without bubbles, other countries about the scary, stirring

- Q: What are the production processes and raw materials of float glass?

- The qualified mixture is then sent to a glass furnace, and in the range of temperature, a uniform glass solution is obtained by melting, clarification, homogenizing and cooling. The glass liquid through the flow passage and launder into the tin bath filled with protective gas of nitrogen and hydrogen, floating on the surface of molten tin, complete glass liquid natural tree, thin, flat show polishing, after cooling, with glass transition roller table hold left into the annealing annealing and tin bath. The annealed glass band can be taken as a product after cutting, checking and packing.

We manufacture high-tech products, mainly including transparent glass ceramic, black ceramic glass, porcelain white glass ceramic, ceramic containers and so on. Our products are mainly applicable for electric furnaces, induction cookers, highlight cookers, electric ceramic heaters, microwave ovens, ovens, physiotherapy instruments, gas stoves, cooking utensils, fireplaces, observation windows and so on.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe |

| Company Certifications | ISO 9001:2000 ;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Ningbo, Shanghai |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 50,000-100,000 square meters |

| No. of Production Lines | 7 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Low |

Send your message to us

Microcrystalline Glass-7

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches