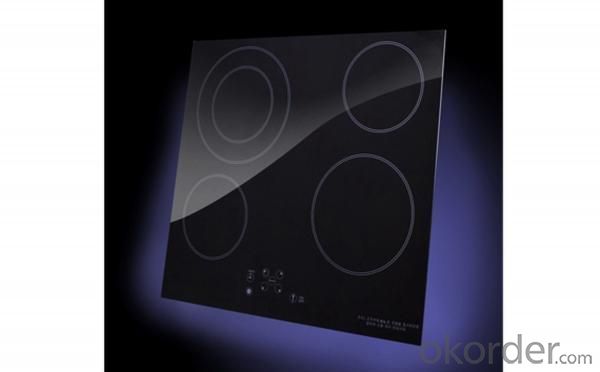

Microcrystalline Glass-2

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

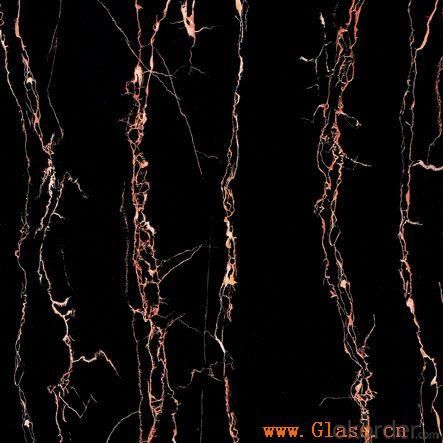

Microcrystalline Glass(Glass-ceramics) are polycrystalline material produced through controlled crystallization of base glass.

- Q: What role does zircon sand play in the production of glass? Is it a raw material for glass or a production process?

- Zircon sand is the most important zirconium containing mineral, which has the widest distribution, largest reserves and most types in zirconium minerals. It is a kind of mineral with zirconium silicate as the main component. Zircon sand is the main raw material for preparing zirconium, hafnium and many kinds of zirconium products. It has the characteristics of high melting point, low thermal conductivity and small coefficient of linear expansion. It is widely used in metallurgy, casting and other industries.Zircon sand (Gao Yingshi) is highly resistant to heat and has a melting point of 2750. Acid corrosion resistance. 80% of the world's direct use in the foundry industry, ceramics, glass industry, and the manufacture of refractory materials. A small amount used in ferrous alloys, pharmaceuticals, paints, tanning, abrasives, chemicals, and nuclear industries. Very little is used in smelting zirconium metal.

- Q: Civil construction projects, exterior wall glass curtain wall raw materials, or construction process, or the end of the construction, what tests should be done?

- Curtain walls shall be tested for raw materials and field inspection shall be carried out at the construction site. Including pullout test, water resistance test, etc., in details, you just need to read the data form

- Q: The main chemical constituents of ordinary glass

- Glass is a silicate product that we can see every dayThe window glass is the most common glass, the glass is called ordinary glass. Manufacture of ordinary glass raw material is sodium carbonate, limestone and quartz. The production, the raw materials are crushed and mixed in proper ratio, add heat strengthened glass kiln. Raw material melting happened after the complex physical and chemical changes. Which is the main reaction:Na2CO3SiO2 Na2SiO3CO2 hav'eCaCO3SiO2 CaSiO3CO2 hav'e

- Q: What is the difference between acrylic board, lotus board, organic board and PVC board?

- Acrylic board is a kind of chemical material. Chemistry called "PMMA" is a polyacrylate, commonly known as "after the special treatment of plexiglass", in the application industry, acrylic raw materials in general in the form of particles, plates, pipes and other forms. Organic glass acrylic and special processing, organic glass products, light boxes with acrylic production has good transparence, pure color, rich colors, beautiful smooth, both day and night of two kinds of effect, long service life, does not affect the use of other features, in addition, acrylic and aluminum plate material, advanced screen printing etc. can be the perfect combination, to meet the business needs of acrylic plastic is to improve the store level business, unified enterprise image of the best form of outdoor advertising.

- Q: Not man-made destruction, why toughened glass suddenly broken?

- There are a variety of predisposing factors 2. tempered glass explodeFor example, A. before the installation of glass is accidentally damaged, like chipping, knocked the feet, because the glass is tempered around the weak area, its strength even weaker than the non tempered glass, but this part of the damage are not likely to cause the glass immediately burst, but changed the internal stress of glass. When the upper wall is used, the internal stress changes gradually, which breaks the glass.B. such as differences in temperature after installation. As you say, temperature, weather, and so on, will make the internal pressure of the glass partial uneven, thus causing burst.Is there a correct size for the C. installation?. If the installation is too tight, the specifications are not appropriate, it will cause stress changes inside the glass, causing a burst.D. the rest is external force, including impact, extrusion and so on. It's not just human impact, or other things, or even wind in nature. If the glass does not fall on the ground, there will be the point of impact (if it is obvious, there will be explosive, Hu Dieban) these can be invoked, but if in the proceedings can only be said to be a possibility, because you have no evidence to prove that. In the domestic situation, the glass manufacturers generally compensate for the glass trouble.

- Q: The main reasons for failure of air glass are outlined

- The requirements of the desiccant performance must have low initial adsorption capacity, easy production and operation, while the remaining strong adsorption capacity, ensure the sealing hollow glass has more adsorption capacity and only adsorption, water molecules with wear strength, usually choose 3A molecular sieve as a special adsorption of hollow glass as for the special agent, contain volatile sealant, special ability requirements of desiccant adsorption of organic molecules, the general choice of 13X molecular sieve, molecular adsorption as water and adsorption of organic compounds by sieve. The desiccant absorption capacity of the water vapor as the desiccant temperature varies, different desiccant absorbs water vapor in a given number of different temperature conditions, depending on the hollow glass cavity obtained rate of water vapor, water vapor growth rate is a function of several factors

- Q: What kind of glass is smoked glass?

- * basic materials for glass makingSilica is the main raw material made of silica on the earth reserves is great. Silica is the main raw material for the main raw material is made of glass stones. The silicon content of different rocks are different. In our life of these materials is the most common.

- Q: What kind of material is the toughened glass film made of mobile phone?

- The low iron glass toughened ultra white suede;To enhance transmittance, a layer of antireflective coating is also applied to the front of the glass

- Q: What is the raw material of glass? How is it converted to glass?

- According to the designed material sheet, the raw materials are weighed and mixed evenly in a mixer. The main raw materials of glass are: quartz sand, limestone, feldspar, soda ash, boric acid and so on.

- Q: Is the price of glass raw material the biggest proportion of quartz?

- In the long run, quartz is a non renewable energy source, and the trend is rising for a long time.

We are the professional producer of electronics glass.Our company has advanced technology and equipment.We have a management team rich in professional experiences and one of the top technical teams in the glass industry, and has advanced quality glass manufacturing in China over the past twenty years.

1. Manufacturer Overview

| Location | Zhejiang |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | Taiwan; Southeast Asia |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 70,000 square meters |

| No. of Production Lines | 16 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Microcrystalline Glass-2

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches