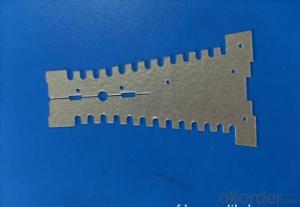

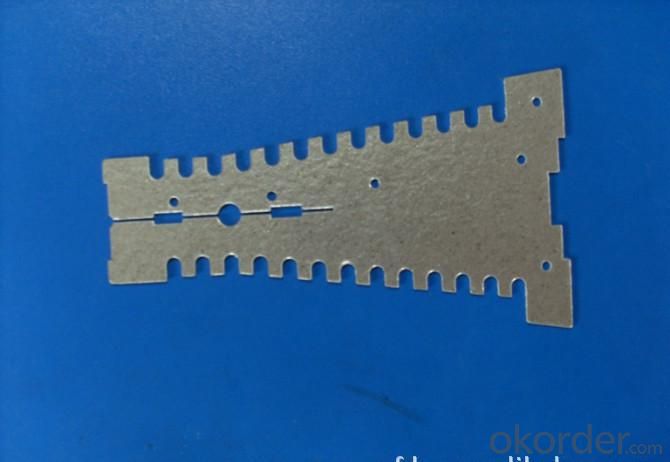

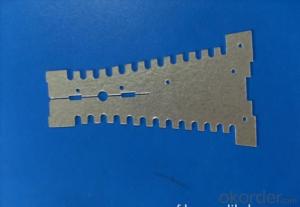

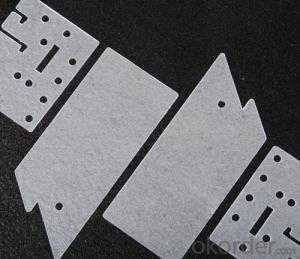

Special Sized Mica Plates Used in Electric Iron

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction:

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C).

Mica plate is made of mica paper with highperformance organic silicon resin. After heating and pressing, the mica plate can be made into rigid or flexible insulating plates. The mica content is about 90% and the organic silicon resin content is 10%.

2. Main features of Mica Parts:

Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

3. Application:

Typical applications of mica heating elements are air heaters, enclosure systems, food service equipment, process and packaging equipment.

4. Technical Parameters:

MICA SHEET -----Technical data | ||||||||

ITEM | UNIT | RM | RP | RM-T | RP-T | FM | FP | |

Hardness |

| Rigid | Rigid | Rigid | Rigid | Flexible | Flexible | |

Mica paper |

| Muscovite | Phlogopite | Muscovite | Phlogopite | Muscovite | Phlogopite | |

Thickness | mm | 0.1-2.0 | 0.1-2.0 | 3.0-50 | 3.0-50 | 0.1-2.0 | 0.1-2.0 | |

Mica content | % | ≥90 | ≥90 | >88 | >88 | ≥90 | ≥90 | |

Bond Content | % | <10< span=""> | <10< span=""> | <12< span=""> | <12< span=""> | <10< span=""> | <10< span=""> | |

Density | g/m 3 | 1.6~2.45 | 1.6~2.45 | 2.1~2.4 | 2.1~2.4 | 1.6~2.45 | 1.6~2.45 | |

Heat | Continuous | ℃ | 500 | 700 | 500 | 700 | 500 | 700 |

Peak | ℃ | 700 | 900 | 700 | 900 | 700 | 900 | |

Heat loss at 500℃ | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | <1< span=""> | <1< span=""> | |

Heat loss at 700℃ | % | <2< span=""> | <2< span=""> | <1< span=""> | <2< span=""> | <2< span=""> | <2< span=""> | |

Flexural strength | Mpa | >160 | >140 | — | — | <1< span=""> | <1< span=""> | |

Water absorption 24h/23°C | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | — | — | |

Dielectric strength | KV/mm | >20 | >20 | >15 | >15 | >15 | >15 | |

Volume | 23℃ | ΩNaN | >1017 | >1017 | >1017 | >1017 | — | — |

500℃ | ΩNaN | >1012 | >1012 | >1012 | >1012 | — | — | |

Smoking Test | s | <4< span=""> | <4< span=""> | — | — | — | — | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q: What is the 8 ° C rule for insulating materials?

- The service life will be greatly shortened, such as ATR insulation material limit working temperature of 105 ℃, when the ultimate working temperature of 8, the life will be reduced by about half, which is the so-called 8 ℃ thermal deterioration rules

- Q: Brass is not an insulating material?

- Brass is a particularly good conductive material and is a good material for wearing heat

- Q: Insulation material and the definition of the role of the best professional insulation materials website for my reference

- The main indicators affect the performance of insulating materials 1, insulation resistance, resistivity: resistance is the reciprocal of conductance, the resistivity is the resistance per unit volume. The smaller the conductivity of the material, the greater the resistance, the reciprocal relationship between the two, for the insulation material, always want the resistivity as high as possible. 2, the relative dielectric constant and dielectric loss tangent:

- Q: Who knows what are the ability of 1300 degrees above the high temperature, insulation materials?

- Heat-resistant polymers can be used as high temperature resistant film insulation materials, high temperature resistant fibers, high temperature resistant coatings, high temperature adhesives. In accordance with the high temperature of the time, but also sub-instant high temperature materials and high temperature materials for a long time. The former in 1000 ~ 10000 ℃ can withstand a few seconds to a few minutes.

- Q: What insulating materials do you need for power tools?

- Reinforced insulation: the voltage between the live parts and the accessible housing is 3750V, such as the voltage between the brush and the cover surface; double insulation: basic insulation + additional insulation. Main insulating material: green paper or DMD Insulation paper for basic insulation; shaft insulation and plastic housing for additional insulation; rotor insulation end plate, stator insulation end plate, used to control the creepage distance and electrical clearance; brush grip bakelite powder, used to strengthen the insulation; other parts (Power plugs, commutators, switches, etc.) These are pressure requirements.

- Q: What is the insulating material in the middle of the connecting wire?

- The original wire is insulated paint, you often use, you can also use quick-drying insulating paint.

- Q: What are the gas insulation materials?

- Gas insulation material refers to air, nitrogen, sulfur hexafluoride and other gases

- Q: Wear-resistant, high temperature, insulation materials which

- Polytetrafluoroethylene (engineering plastics) - (- 195 ~ 250) ℃ can be used for a long time. For corrosion-resistant parts, anti-friction wear parts, seals, insulation and so on. Silicone rubber - Upper temperature limit (100 to 300) ° C. For high and low temperature parts, insulation, pipe joints and so on. Fluorine rubber - the use of the upper temperature of 300 ℃, for chemical lining, senior seals, high vacuum plastic parts.

- Q: What are the electrical insulation materials

- Electrical insulation materials are wood, cotton, paper, oily paint, asphalt paint, polyester film, glass cloth, mica, glass fiber, asbestos, composite silicon organic polyester paint, quartz, glass, porcelain material.

- Q: What insulating material is best `?

- Gas insulation material has a high ionization field strength and breakdown field strength, after the breakdown can quickly restore insulation performance, chemical stability, non-combustible, non-explosive, non-aging, non-corrosive, easy to discharge decomposition, and greater heat capacity , The thermal conductivity, and the flowability are all. The air is the most widely used gas insulating material, for example, between the overhead wires of the AC and DC transmission lines, and the overhead wires are insulated by air. The high voltage standard capacitors also use gas insulating media (SF6) .SF6 is also used in the manufacture of high-voltage circuit breakers, metal-enclosed combination of electrical appliances, gas-insulated transmission pipeline cables and gas-insulated transformers, etc., the use of high-pressure nitrogen or carbon dioxide.

Send your message to us

Special Sized Mica Plates Used in Electric Iron

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches