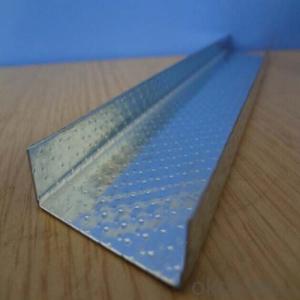

Metal Studs Galvanized Metal Track Furring Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 550000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Goods:

1, Name :Furring Channel/metal studs/strack

2, Place of Country: China

3, Application: Ceiling partion

Specification for middle east:

Main Channel 38*12

Furring Channel 68*35*22

Wall angle 25*25

C stud 50*35

C Stud 70*35

C stud 75*35

U track 52*25

U track 72*25

U track 75*25

Specification to Australia:

top cross rail 25*21*0.75

25*21*0.75

Furring Channel 28*38*0.55

16*38*0.55

Furring Channel track 28*20*30*0.55

16*20*30*0.55

Stud 64*33.5*35.5

76*33.5*35.5*0.55

Stud 92*33.5*35.5*0.55

150*33.5*35.5*0.55

Track 51*32*32, 64*32*32*0.55

76*32*32*0.55

Track 92*32*32*0.55

Specification to Europe, Russia, Ukraine, Georgia. ect

C Stud 60*27

U track 28*27

C stud 50*50

C stud 75*50

C stud 100*50

U track 50*40

U track 75*40

U track 100*40

Advantages of Galvanized Steel Profile:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3.Warm sales in Middle East , Africa , Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services

4. The specification can follow up customer requirments.

5. Advanced equipment can make sure exactly size, high quality products.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures

- Q: 75 series of light steel keel wall double-sided double-layer 12 thick plaster board filled with sound insulation noise can reach the number of decibels

- Light steel keel gypsum board system is usually double-sided wall structure, that is, "plate - keel (cavity) - plate" structure, each side of the wall board for the single or double gypsum board, Light steel keel. In order to obtain better sound insulation effect, in the cavity filled with rock wool board or glass wool.

- Q: Shanghai light steel keel ceiling, wall quotes

- Depends on the use of good and bad materials. Ordinary ceiling also 30-40, partition 35-45, I was doing this is what the project. Can contact me. Offer

- Q: What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- Well, I think so, I found two companies were quoted, the price is almost, but the listed materials are not the same.

- Q: Gypsum board partition wall how to sound insulation

- Brush the EL1230 interface agent with hungry wolf adhesive paste Yanmian insulation board, and then apply anti-cracking mortar protective layer.

- Q: PVC plastic buckle the corners of the corner is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall surface and ceiling how fixed

- Plastic buckle the corners of the line, the normal practice for the eye plug plug stopper, with self-tapping screws fixed. Plastic buckle has its own slot, in the male slot with self-tapping screws fixed on the keel. Light steel keel gypsum board wall, with the heaven and earth keel to the ground in the ground punching cork with nails fixed; Tianlong the same.

- Q: 100 square light steel keel wall how many pieces of heaven and earth keel

- Heaven and earth keel accurately depends on the length of the wall, the dragon than the dragon multi-hole size. Usually can be doubled the length of the wall to remove the door. Vertical spacing is usually 400, the door has to strengthen the vertical keel, wearing a keel to see the height of the wall, you can 1, but also two. Depending on the specific design. If the height of 3m, heaven and earth keel to 67m-several door size.

- Q: Use light steel keel to do the shelf, install the glass partition wall, this process is feasible? How about construction?

- Yes, according to the provisions of the standard fixed light steel keel, glass fixed hole, to ensure that the glass transparent and clean, surrounded by transparent glass glue. In the space can be added to the items and so on

- Q: Can the gypsum board be painted on the wall

- Direct big screw can be because the back of the painting has a rope directly linked to such a simple question without the whole too much trouble

- Q: Light steel keel gypsum board partition design should pay attention to what the problem

- In order to be able to make decoration more perfect, it is recommended that you choose the decoration manufacturers, to be careful, we must choose the same brand of all products. The

- Q: Do light steel keel gypsum board partition to pay attention to what matters?

- After the installation of the gypsum board, the paper gypsum board installation and the ground to stay in the gap, so as not to drag the ground to do when the tide back. If you consider the sound effects can be filled with sound-absorbing cotton, but the effect is not good. Really too loud, you can use cotton plug The

Send your message to us

Metal Studs Galvanized Metal Track Furring Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 550000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords