Drywall Metal Studs and Track Main Channel and Furring Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Suspension System) Description

As an authorized trading facility, Shanghai Microcherry Information Technologies (MCI) focuses on providing high quality products by offering premium services to customers.

As the original manufacturer, Shanghai Hanhan Hardware Factory works with engineers having more than 15 years experience, and manufactures various types of galvanized light steel profiles for years, such as drywall & partition system, ceiling system, plasterboards, applying to all kinds of houses, hotels, factories production and sales integration.

2,Main Features of the (Suspension System)

Advantages of Galvanized Structural Steel Profile:

1. Raw material is high quality hot dipped zinc galvanized steel strip, good fireproof and heat insulation, waterproof and antirust, anticorrosive, high durability;

2. Hot dipped zinc galvanized steel strip zinc coating is 80-180g/m2;

3. Double sized galvanization volume make sure that the plaster bone is corrupt and rust resistance.

4. Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have with an excellent reputation of high quality and services;

5. High quality raw material guarantees the light steel keel of life and good performance of construction;

6. Equipped with ten precision cold rolled steel strip production line;

7. Waterproof and antirust, anticorrosive, high durability

8. OEM is available.

9. Application:

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories, office, house, airplane-terminal buildings, bus stations, waiting lounge, etc.

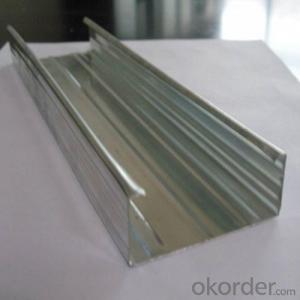

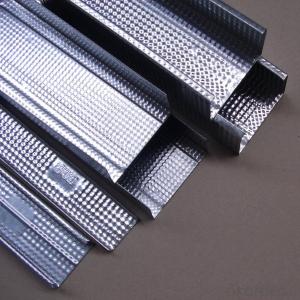

3,(Suspension System) Images

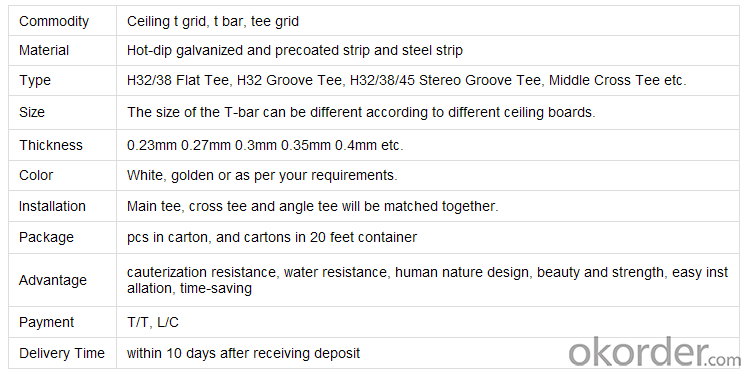

4,(Suspension System) Specification

5,FAQ of (Suspension System)

No.& Name | METAL STUDS & TRACKS |

Base Materials | 80g-120g / sqm galvanized steel |

SIZE | 38,50,60,75,100,150mm,thickness from 0.3mm-2.0mm. Can produce according to customer requirement |

Features | Good machine performance, high strength & light self-weight, fire-proof, dampproof, heat insulation ,high durability , high rust resistance, high-intensity and good-antisepsis |

Operating | Short-time instuction, easy working, it a new decorative material |

Function | Fit for shopping mall, hospital, offices, banks, hotel, facory, etc. |

Ceiling channel and drywall channel, made of high-quality galvanized Steel, adopting laminose strut channel by Cold-formed Technology, are a kind of metal framework made after several continuous rolling.

Ceiling keel and wall channel has light-weight, high-intensity, good-antisepsis and other advantages. They mainly match to paperbacked plasterboard and other goods, also the other plates such as GRC, FT and so on.

- Q: Now what is the room wall material is fashionable? Environmentally friendly

- Sound insulation cotton how to be environmentally friendly too old and toxic The best material is lightweight partition wall insulation insulation and non-toxic light foam cement board wallboard calcium silicate partition board and keel plus paint-free green frog Non-toxic dalfers are currently my best found some non-toxic

- Q: Light steel keel wall circuit how to wear pipe

- Separate the laying of the wall: According to the architectural design, in the indoor floor of the floor wall and the edge of the line, and cited to the two main structure of the wall and the bottom of the floor, while pop the door and window hole line.

- Q: Shanghai light steel keel ceiling wall how much labor costs?

- Do not know how much of your area may be a little expensive point of the ceiling 10 yuan / square wall 80 / side less expensive to the point is not the same everywhere, roughly in the 20 to 25 or so labor price.

- Q: Light steel keel wall waterproof

- Used to resist external UV radiation, natural aging and chemical corrosion, effectively extend the coating use

- Q: 4 m long prefabricated board can do light steel keel double gypsum board wall?

- Yes, because the prefabricated board toughness is better, and its specifications are not the kind of chunks, if the chunk can withstand the weight will be reduced in the middle of the possibility of falling to increase .. Light steel keel wall itself The weight is not heavy, coupled with the ceiling is also force, then the weight of the ground will be reduced accordingly

- Q: Gypsum board wall above the good paint glass?

- Gypsum board partition wall construction operation process: (1) According to the design drawings, in the already done walls, floors, the ground release off the line, the door hole edge. (2) according to the design drawings and the actual size, with a wheel cutting machine cutting keel and classified stacking. (3) according to the line has been put away and the door edge, with nails or expansion bolts to the ground keel fixed on the ground floor, nail or expansion bolt spacing 600mm. The top of the keel into the wall of the reserved hole 100mm, and then use cement mortar packing fixed, or with nails, expansion bolts to the end of the handle along the top keel fixed to the wall. (4) According to the cut line and the edge of the door, according to the size of the file size layout, painted in the edge, along the top keel, less than the modulus should be placed in the partition with the wall at the first board. (5) According to the document mark will be cut in advance of the length of the vertical keel in turn inserted along the edge, along the top keel groove, the flange towards the direction of the proposed panel to be installed. Adjust the vertical, positioning accuracy, with rivets fixed. The vertical keel on the wall is fixed to the wall with a nail or expansion bolt, and the distance between the nail or the expansion bolt is 1m. (6) the installation of doors and windows to strengthen the installation of the keel: the first installation of the hole on both sides of the vertical reinforcement keel, and then install the hole up and down to strengthen the keel, and finally install the big hole on both sides of the upper and lower reinforcement keel and bracing. (7) Install the cross brace and support card. The vertical keel fastened, so that the entire partition keel has sufficient strength and stiffness.

- Q: 100 square light steel keel wall how many pieces of heaven and earth keel

- Heaven and earth keel accurately depends on the length of the wall, the dragon than the dragon multi-hole size. Usually can be doubled the length of the wall to remove the door. Vertical spacing is usually 400, the door has to strengthen the vertical keel, wearing a keel to see the height of the wall, you can 1, but also two. Depending on the specific design. If the height of 3m, heaven and earth keel to 67m-several door size.

- Q: How to fix the middle of the light steel keel to the roof and the ground, the keel has a joint?

- First with the expansion bolts fixed heaven and earth keel and roof and the ground, the middle with a vertical keel; if the layer is too high, then the keel will have joints, of course, have special connections.

- Q: How to construct double - sided double gypsum board partition wall

- Vertical keel sub-file: According to the location of the wall defense door openings, in the installation of the top keel, according to the specifications of the panel panel width, sub-file size 450mm, less than the modulus of the file should avoid the first box Plate position, so that the edge of the gypsum cover panel is not out of the box. Installation of horizontal card keel: According to the design requirements, wall height greater than 3m should be added to the horizontal card retaining keel, mining core pulling rivets or screws tied to fixed

- Q: Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Wood keel is best used, one is poor fire, the second is easy to produce pests, and now the ceiling are gradually replaced by light steel keel keel.

Send your message to us

Drywall Metal Studs and Track Main Channel and Furring Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords