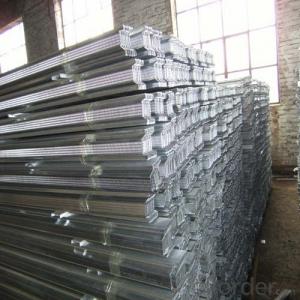

Ceiling Profile Metal Steel Profile Channel for Drywall and Gypsum Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Metal Steel Profile Channel For Drywall for Gypsum Board

Instruction

Drywall Metal Profile

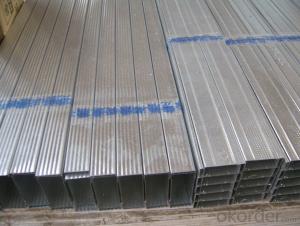

Drywall ceiling Channel is galvanized metal structure used in non-bearing partition systerm .

Drywall steel frame system is a popular way to be used to divide the space,especially using in commercial buildings.

Drywall Steel Frame System is made of galvanized steel sheet with good rust-Proof function.A variety of frames are ready for customers' demands and designers' choice for different purposes and places. One of our merits is the special hole for channel on C-stud in per 6Ocm which is easy for workers to install the electric lines and water tubes.CH and IH type of studs are the special type we developed to solve the hard work situation in elevator ventilator and offer a better protection of workers' safety.

Our dry wall steel frames are covered with magnesium fireproof boards and fulfilled with material which is heat insulation and noise-proof mineral wool between two layers of boards. It will create a better living environment than the traditional building materials.

Suspension ceiling structure,Galvanized metal structure which is the vertical metal framework used in non-bearing partition system.

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe,

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Metal Steel Profile Channel For Drywall for Gypsum Board

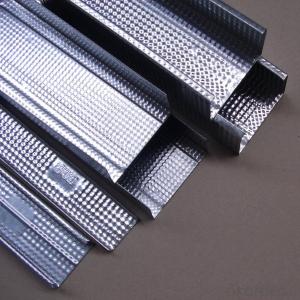

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa ,

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

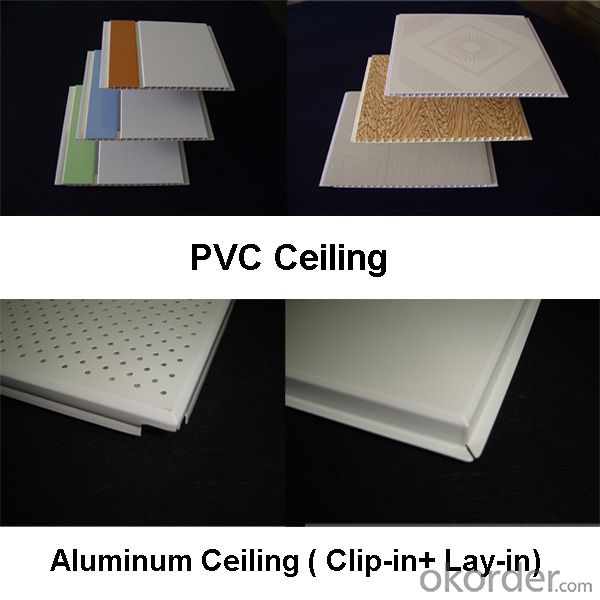

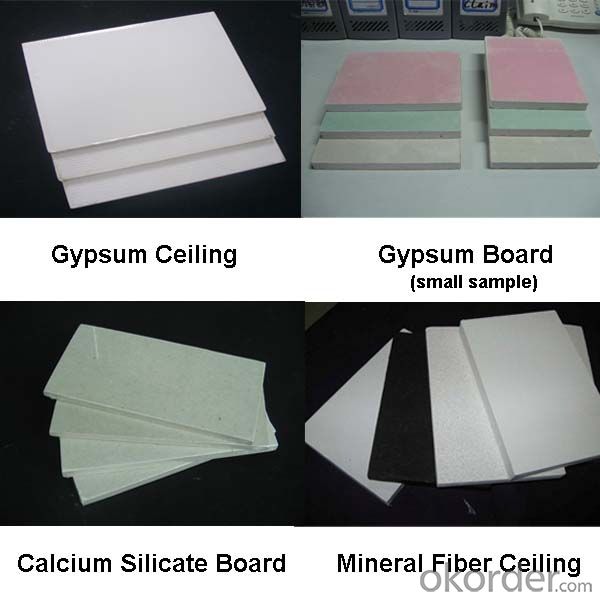

Other products we supply:

Metal Steel Profile Channel For Drywall for Gypsum Board

- Q: What is the general ceiling of indoor ceiling?

- Upstairs copy of the good. Really quite detailed. That I also talk about it. Light steel keel wood keel aluminum buckle plate steel plate plaster board sauna board

- Q: Construction works: light steel keel partition in a ceiling ceiling, the height should be calculated to the ceiling ceiling or calculated to the bottom of the concrete floor?

- When calculating the area of the ceiling, the cross section of the light steel keel shall be reduced.

- Q: Toilet integrated ceiling with good or good light steel keel good

- Of course the light steel keel is good. Wood keel gradually not used in the bathroom, the ceiling is not ventilated, a long time will be wet moldy. Reminded one, many brands of multi-grade ceiling, to their own to compare the choice of different stores.

- Q: Wood keel expensive or light steel keel expensive?

- Hello there! Wood keel with light steel keel which expensive? There are two possibilities, if the material by material to measure the two materials, it is light steel keel expensive. If used in the project of the ceiling, in accordance with the standard construction process construction, that light steel keel cost will be cheaper.

- Q: Decoration light steel keel ceiling in the side of the keel main keel vice keel What is the meaning?

- The main keel is generally carrying keel, vice keel is connected to carry keel and gypsum board, while the keel is used in the wall around to fix the main keel

- Q: Tectonic levels and practices of light steel keel

- Very professional, simply say something: 1 original top hole, with expansion screw connection line pole fixed. 2 on the main dragon leveling 3 in the main dragon connected to the deputy lord leveling 4 gypsum board with self-tapping screws fixed

- Q: Light steel keel ceiling cad chart

- There is a special light steel keel construction of the chart to sell, you can buy a set, only tens of dollars, inside the various forms of light steel keel ceiling, partitions have detailed construction techniques and regulatory requirements

- Q: Light steel keel ceiling budget how to calculate

- Hanger Light steel keel material accounting A ceiling Verification according to the construction plan on the ceiling structure and size, respectively, the calculation of each indoor ceiling of the main keel and vice keel number, and then the chamber The total number of primary and secondary keels required to add the total number of M. Taking into account the size of the construction specifications and the actual size of the difference, as well as the construction of the truncation loss and other factors, the need to add the total 3% margin, so that can be practical The total number of M required is in meters (m). The empirical formula is: M total = 1.03M Note that the total number of primary and secondary keel should be calculated separately, such as the main and vice keel of the same material, you can also be calculated.

- Q: Integrated ceiling and ordinary and wood keel ceiling difference and good or bad?

- Integrated are aluminum alloy material, a special keel is relatively flat, light source Yuba exhaust fan are tailor-made tailor-made sensory is very beautiful but also durable but the spread is also a great traditional buckle ceiling (the main material + artificial Fee) generally in the 60 ~ ~ 120 or so with the integration may be more than 200

- Q: Ceiling with light steel keel size is generally how much

- Wall steel ceiling keel specifications and information decoration materials Light steel keel wall materials are 50, 75, 100, 150 and several other Light steel keel thickness ranging from 0.4mm to 2.0mm.

Send your message to us

Ceiling Profile Metal Steel Profile Channel for Drywall and Gypsum Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches