Metal Profile for Waterproof Gypsum Board Drywall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Metal Profile for Waterproof Gypsum Board Drywall

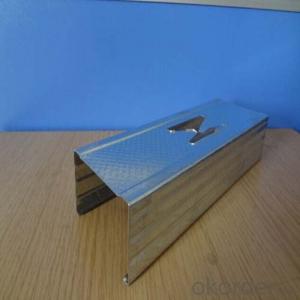

Drywall channel system some sizes as follows:

a) Stud:

70x35x3000x0.45/0.5/0.6mm

50x35x3000x0.45/0.5/0.6mm

b) Track:

72x25x3000x0.45/0.5/0.6mm

50x25x3000x0.45/0.5/0.6mm

Furring ceiling system some sizes as follows:

a) Furring channel: 35x22x12x300x0.45/0.5/0.6mm

b) Main channel: 38x10(12)x3000x0.45/0.5/0.6mm

c) G.I. Wall angle:

25x25x3000x0.45/0.5/0.6mm

23x23x3000x0.45/0.5/0.6mm

22x22x3000x0.45/0.5/0.6mm

20x20x3000x0.45/0.5/0.6mm

Galvanized steel profileTechnicology:

1.adopting high-grade quality hot-dipped galvanized steel,

2.The products surface zero spangle,and intensity toughness, besides, it can add 20% more than common product.

Features of steel stud

1, advanced equipment, production technology, advanced detection methods of science, the product surface, rolling, high precision, beautiful shape, straight;

2,Using the high quality continuous hot-dip galvanizing cold-rolled coil for the base material ,material evenly ,moderate hardness , light weight ,fireproof, combination convenience , Not subject to seasonal effects, the construction simple and quick, greatly shortening the duration and improve the working efficiency;

3, the steel stud have good corrosion resistance ability, long service life;

4, Cross-section structure is reasonable, humane design: Keel, Vice keel and vertical played pitting self-tapping screw designed to effectively prevent sideslip, improve the construction speed, Vice-keel edge of the stiffener designed to enhance the steel keel, anti-subsidence more capable, the level of vertical keel edge design makes perfect fastening, an increase of product application design.

Application

1,Supermarket, marketplace

2,Underground, air port, bus station

3,Building lobby,metro station

4,Hotel, restaurant,railway station

5,School, office, meeting room ,hospital

6.commercial building

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

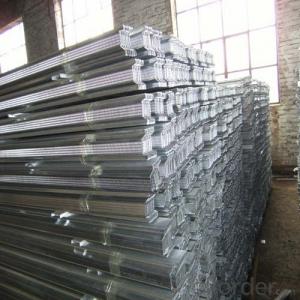

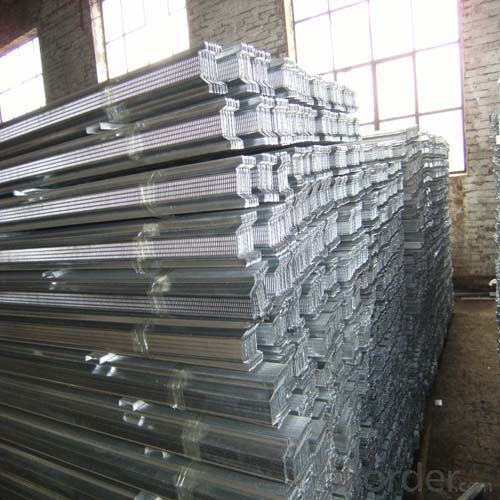

Pictures:

- Q: I was not a tool in the category, or else I got myself!

- I think you do so sound insulation is not the middle of the need to add sound insulation materials. There are many kinds, such as noise insulation cotton class. The more types of composite materials, the more layers, the sound and sound effects the best. It is best to have sound and sound effects have to reduce the sound of the rebound.

- Q: The room to remove the partition, can not retain the original light steel keel gypsum board ceiling?

- It is possible that you said that the wall above is a beam, so that when you remove the wall, the gap between the two ceilings to do a false beam to solve. But if this place did not beam, then we must consider the demolition or not split!

- Q: Light steel keel should be how to strengthen, in order to make solid wood door installed more prison?

- Has been reinforced with wood, had not wanted to choose light steel keel is not considered too tight, not the reason for noise, but because these two bolt doors are not out from the original wall, decorating company recommended with light steel keel, So I did not insist, but there are 2 stack walls I insist they use brick

- Q: Is it good for brick walls or light walls?

- In fact, what can be used, but to consider other factors: ???? If your house is covered by their own, that no problem, the whole red brick line. ???? If your house is the house which developers to develop, in which district, but also high-level, that in addition to the water can be used red brick, other places can not be used, for example, the toilet wall will use red brick The ???? Lightweight brick, to paint before the top of the best home to a layer of steel mesh, or else after the brick in the junction will crack.

- Q: Can my light steel keel ceiling withstand the weight?

- According to your argument is no problem. Please feel free to use it

- Q: PVC plastic buckle the corners of the corner is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall surface and ceiling how fixed

- Plastic buckle the corners of the line, the normal practice for the eye plug plug stopper, with self-tapping screws fixed. Plastic buckle has its own slot, in the male slot with self-tapping screws fixed on the keel. Light steel keel gypsum board wall, with the heaven and earth keel to the ground in the ground punching cork with nails fixed; Tianlong the same.

- Q: 100 square light steel keel wall how many pieces of heaven and earth keel

- Heaven and earth keel accurately depends on the length of the wall, the dragon than the dragon multi-hole size. Usually can be doubled the length of the wall to remove the door. Vertical spacing is usually 400, the door has to strengthen the vertical keel, wearing a keel to see the height of the wall, you can 1, but also two. Depending on the specific design. If the height of 3m, heaven and earth keel to 67m-several door size.

- Q: In a layer of 6 meters high in the big room, do 2.8 meters high light steel keel partition. Big room to do mineral wool board ceiling, how to connect the two?

- Can be directly connected, but not solid. How are they all know what they are.

- Q: Light steel keel installed security door how loaded really

- Light steel keel its own strength is not very good, anti-theft door directly fixed on the light steel keel, then open the door will have a great impact on the light steel keel wall.

- Q: With light steel keel gypsum board do partition wall price how to count?

- Double-sided labor costs more than 20 yuan per square meter, the material to see the grade of gypsum board and the thickness of the keel. Generally not more than 20 yuan per level. Plus freight and handling costs, loss. Offer 60 yuan per flat can be.

Send your message to us

Metal Profile for Waterproof Gypsum Board Drywall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords