Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber by CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

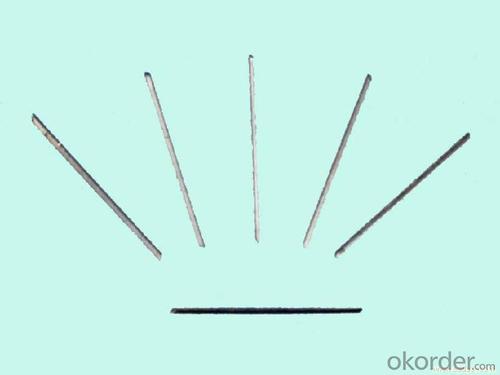

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: Does melt extract stainless steel fiber improve the resistance to freeze-thaw cycles of concrete?

- Concrete's resistance to freeze-thaw cycles is indeed improved by melt extract stainless steel fiber. By incorporating stainless steel fibers into the concrete, its durability and performance are enhanced as the detrimental effects of freeze-thaw cycles are minimized. When water freezes within the concrete, it expands and applies pressure on the surrounding matrix, leading to cracks and eventual deterioration of the structure. Nonetheless, the inclusion of melt extract stainless steel fibers helps address these issues. These fibers serve as reinforcement within the concrete, imparting additional strength and preventing crack propagation. This reinforcement effectively boosts the concrete's resistance to the damaging effects of freeze-thaw cycles. Moreover, melt extract stainless steel fibers possess exceptional corrosion resistance properties, further contributing to the concrete's improved durability. Unlike other fiber types, stainless steel fibers do not corrode or degrade over time, ensuring their long-term effectiveness in enhancing freeze-thaw resistance. In summary, the addition of melt extract stainless steel fiber significantly enhances concrete's resistance to freeze-thaw cycles, preventing cracks and extending the structure's lifespan.

- Q: How does the addition of melt extract stainless steel fiber affect the durability of concrete?

- The addition of melt extract stainless steel fiber can greatly enhance the durability of concrete. Stainless steel fibers are known for their high tensile strength, corrosion resistance, and excellent durability properties. When these fibers are incorporated into concrete, they create a three-dimensional reinforcement network that significantly improves the concrete's resistance to cracking, spalling, and other forms of damage. The stainless steel fibers act as reinforcement within the concrete matrix, providing additional strength and toughness. This reinforcement helps to prevent the propagation of cracks, thereby reducing the risk of structural failure. The fibers also enhance the concrete's resistance to impact, abrasion, and fatigue, making it more durable in harsh environments or under heavy loading conditions. Furthermore, the corrosion resistance of stainless steel fibers ensures that the concrete remains robust even in aggressive environments. Unlike traditional steel reinforcement, which is susceptible to corrosion and can lead to concrete deterioration, stainless steel fibers remain unaffected by moisture, chemicals, and other corrosive agents. This resistance to corrosion extends the lifespan of the concrete structure and reduces the need for costly repairs or maintenance. Overall, the addition of melt extract stainless steel fiber significantly improves the durability of concrete. It enhances its strength, toughness, resistance to cracking, impact, abrasion, and fatigue, while also providing excellent corrosion resistance. This makes concrete structures more resilient, longer-lasting, and more cost-effective in the long run.

- Q: How does melt extract stainless steel fiber improve the impact resistance of bridge decks?

- Melt extract stainless steel fiber improves the impact resistance of bridge decks by enhancing the overall structural integrity of the concrete. The fibers act as reinforcement, dispersing the energy from impact and preventing cracks from propagating. This results in increased durability and resistance to impact loads, ensuring the longevity and safety of the bridge deck.

- Q: Does melt extract stainless steel fiber improve the resistance to sulfate attack of concrete?

- Yes, melt extract stainless steel fiber does improve the resistance to sulfate attack of concrete.

- Q: Is melt extract stainless steel fiber suitable for use in bridge construction?

- Yes, melt extract stainless steel fiber is suitable for use in bridge construction. It offers excellent strength, durability, and corrosion resistance, making it ideal for reinforcing concrete structures in bridges. Additionally, its high tensile strength improves the overall structural integrity and longevity of the bridge.

- Q: Can melt extract stainless steel fiber be used in parking lot pavements?

- Yes, melt extract stainless steel fiber can be used in parking lot pavements. It is often added to concrete mixtures to enhance the strength and durability of the pavement, making it more resistant to cracking and wear. The stainless steel fiber reinforcement helps to increase the lifespan of the parking lot and reduce maintenance requirements.

- Q: What is the effect of melt extract stainless steel fiber on the crack width in shotcrete?

- The crack width in shotcrete is significantly affected by the use of melt extract stainless steel fiber. Stainless steel fibers are renowned for their exceptional tensile strength and durability, making them the ideal reinforcement material for shotcrete applications. Upon addition to the shotcrete mix, the stainless steel fibers are uniformly dispersed throughout the material, forming a reinforcement network that enhances its structural integrity. This reinforcement effectively reduces crack width in the shotcrete by bridging the cracks and preventing their propagation. The melt extract stainless steel fibers serve as micro-reinforcement within the shotcrete, amplifying its ductility and resistance to cracking. This is especially advantageous in areas with high stress concentrations or where cracking is prevalent, such as tunnels, underground structures, or retaining walls. By diminishing crack width in shotcrete, the utilization of melt extract stainless steel fibers enhances the material's overall durability and longevity. It elevates its ability to withstand environmental factors, including freeze-thaw cycles, chemical exposure, or mechanical loading, all of which can trigger crack propagation and subsequent deterioration. Moreover, the reduced crack width in shotcrete also enhances its aesthetic appearance by minimizing visible indications of cracking on the surface. This is particularly crucial in architectural applications where the shotcrete is exposed and serves as a decorative element. To summarize, the incorporation of melt extract stainless steel fibers into shotcrete yields positive effects on crack width in the material. It enhances structural integrity, durability, crack resistance, and overall aesthetic appearance, rendering it a valuable reinforcement option for shotcrete applications.

- Q: Can melt extract stainless steel fiber be used in marine construction?

- Yes, melt extract stainless steel fiber can be used in marine construction. Its corrosion resistance and durability make it suitable for applications in marine environments where it will be exposed to seawater and other harsh conditions.

- Q: What is the effect of melt extract stainless steel fiber on the corrosion resistance of concrete?

- The addition of melt extract stainless steel fiber to concrete can significantly enhance its corrosion resistance. Stainless steel fibers are made from a corrosion-resistant alloy, typically containing chromium, nickel, and other elements. When incorporated into concrete, these fibers create a three-dimensional reinforcement system that helps to mitigate the effects of corrosion. Concrete is susceptible to corrosion when exposed to harsh environments, such as chloride-rich or acidic conditions. These corrosive agents can penetrate the concrete and attack the reinforcing steel, leading to structural deterioration and reduced service life. However, the presence of stainless steel fibers in the concrete matrix acts as a barrier, preventing the ingress of corrosive agents and reducing the risk of corrosion. The high corrosion resistance of stainless steel fibers ensures that they remain intact and effective for an extended period. Unlike traditional steel reinforcements, stainless steel fibers do not corrode easily, even under aggressive conditions. This property helps to maintain the integrity of the concrete, providing long-term durability and reducing the need for costly repairs or replacements. Furthermore, the addition of stainless steel fibers also improves the mechanical properties of concrete, such as its tensile strength and crack resistance. This additional reinforcement helps to prevent the formation and propagation of cracks, which can act as pathways for corrosive agents to reach the reinforcing steel. In summary, the incorporation of melt extract stainless steel fiber in concrete enhances its corrosion resistance by acting as a barrier against corrosive agents and improving the overall durability of the structure. This results in a longer service life and reduced maintenance costs for concrete structures exposed to corrosive environments.

- Q: Can melt extract stainless steel fiber be used in self-compacting concrete (SCC)?

- Yes, melt extract stainless steel fiber can be used in self-compacting concrete (SCC).

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber by CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords