Melt Extract Stainless Steel Fiber 446 - High Quality Melt Extract Stainless Steel Fiber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

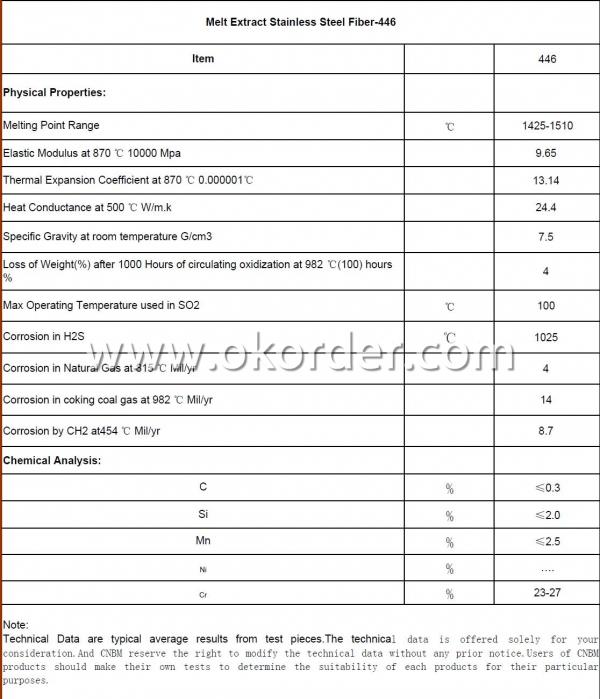

General Information of Melt Extract Stainless Steel Fiber 446

CMAX melt extract stainless steel fiber is produced by melting elements in a crucible. A flywheel is then introduced to the crucible and droplets of molten metal are spun into the open air and hardened.The speed of the wheel determines the fiber length. CMAX melt extract stainless steel fiber can increase the lifetime of refractory materials and industrial furnaces by several times, decreasing cost.

Feature of CMAX Melt Extract Stainless Steel Fiber 446

Improve refractories’performance

Improve refractories’longevity

Improve refractories’durability

Significantly reducing downtime and maintance cost

Application of CMAX Melt Extract Stainless Steel Fiber 446

Refractory products

Precast

Castable project

Industrial furnaces

Other refractories project

Our company has success in its melt extract stainless steel fiber products due to their cost-effectiveness and excellent insulating properties. We also have experience in melt extract stainless steel fiberapplication and would like to assist you in product selection, system design, and installation techniques. Our products of melt extract stainless steel fiber are in good quality and in best price.

- Q: Can melt extract stainless steel fiber be used in fiber-reinforced polymer (FRP) composites?

- Yes, melt extract stainless steel fiber can be used in fiber-reinforced polymer (FRP) composites. The addition of stainless steel fibers enhances the mechanical properties and durability of the composite material, making it suitable for various applications such as construction, automotive, and aerospace industries.

- Q: What is the effect of melt extract stainless steel fiber on the crack width in concrete?

- The crack width in concrete is significantly affected by the utilization of melt extract stainless steel fibers. These fibers are incorporated into the concrete mixture to enhance its durability and strength. In the event of external forces or temperature fluctuations, cracks may develop. However, the presence of stainless steel fibers aids in controlling and minimizing the width of these cracks. The primary reason behind this impact lies in the distinctive properties of stainless steel fibers. These fibers are recognized for their high tensile strength and ductility. When cracks begin to form in the concrete, the stainless steel fibers serve as reinforcement and distribute the stress throughout the matrix. This redistribution of stress helps prevent the cracks from expanding. Furthermore, the inclusion of stainless steel fibers also enhances the overall toughness of the concrete. Consequently, the concrete becomes more resistant to the propagation of cracks. This implies that even if cracks do occur, they are less likely to propagate and cause significant damage. Furthermore, melt extract stainless steel fibers also enhance the overall durability of the concrete. They function as a protective barrier against corrosion, safeguarding the concrete from the detrimental effects of moisture, chemicals, and other environmental factors. This increases the lifespan of the concrete structure and reduces the frequency of repairs or replacements. To summarize, the utilization of melt extract stainless steel fibers in concrete has a favorable impact on crack width. These fibers reinforce the concrete matrix, distribute stress, and prevent cracks from expanding. Additionally, they enhance the overall toughness and durability of the concrete, making it more resilient to crack propagation and extending its lifespan.

- Q: I want 10 tons of steel fiber, urgently, where can quickly supply

- And steel fiber is divided into several products. Having a cutting, end, hook, milling, copper plated, or steel fiber

- Q: What is the effect of melt extract stainless steel fiber on the deflection of concrete beams?

- The effect of melt extract stainless steel fiber on the deflection of concrete beams can be significant. When stainless steel fibers are added to concrete, they improve the overall toughness and ductility of the material. This results in increased resistance to cracking and improved structural performance. The addition of melt extract stainless steel fibers helps to distribute the load more evenly throughout the concrete matrix, reducing the concentration of stress at specific points. This leads to a decrease in deflection, as the fibers reinforce the concrete and prevent excessive bending under load. Stainless steel fibers also enhance the bond between the concrete matrix and the reinforcing steel bars, resulting in improved composite action. This further contributes to reducing deflection in concrete beams. Moreover, the thermal stability of stainless steel fibers allows them to maintain their integrity even at high temperatures. This makes them particularly effective in reinforcing concrete beams subjected to fire or elevated temperatures, as they help to minimize the effects of thermal expansion and contraction. In summary, the addition of melt extract stainless steel fibers to concrete beams has a positive effect on their deflection. The fibers improve the overall toughness, distribute the load more evenly, enhance the bond with reinforcing steel bars, and provide thermal stability. These combined effects result in reduced deflection and improved structural performance of concrete beams.

- Q: Can melt extract stainless steel fiber be used in high-performance concrete mixtures?

- Yes, melt extract stainless steel fiber can be used in high-performance concrete mixtures. This type of fiber enhances the mechanical properties of concrete, such as increasing its tensile strength, crack resistance, and durability. It is particularly suitable for applications that require high-performance concrete, such as structural elements in buildings, bridges, and road pavements, where improved strength and durability are important.

- Q: Can melt extract stainless steel fiber be used in concrete repair applications?

- Yes, melt extract stainless steel fiber can be used in concrete repair applications. Stainless steel fibers are commonly added to concrete mixtures to enhance its mechanical properties and durability. The melt extract stainless steel fibers are typically made using a specialized process that ensures high tensile strength and resistance to corrosion. These fibers can help improve the resistance to cracking, impact, and fatigue loading in repaired concrete structures. Additionally, the stainless steel fibers can also enhance the bond between the repaired concrete and the existing concrete surface, thereby improving the overall integrity of the repaired area.

- Q: Can melt extract stainless steel fiber be used in tunnel linings?

- Certainly! Melt extract stainless steel fiber is a suitable option for reinforcing tunnel linings. Tunnel linings often utilize stainless steel fibers to enhance the concrete's durability and strength. These fibers act as reinforcement, offering additional crack resistance and tensile strength to the concrete. Melt extract stainless steel fibers are particularly beneficial for tunnel linings due to their remarkable resistance to corrosion, an essential quality in an environment where moisture and chemicals may be present. Moreover, these fibers possess exceptional thermal stability, making them suitable for tunnels that may face high temperatures. In summary, melt extract stainless steel fibers are a dependable and efficient choice for reinforcing tunnel linings.

- Q: Does melt extract stainless steel fiber improve the resistance to carbonation of concrete?

- Yes, melt extract stainless steel fiber can improve the resistance to carbonation of concrete. The addition of these fibers helps to enhance the durability and lifespan of concrete by reducing its permeability to carbon dioxide, which in turn minimizes the risk of carbonation and subsequent corrosion of the reinforcing steel.

- Q: How does melt extract stainless steel fiber affect the rheology of self-compacting shotcrete?

- The rheology of self-compacting shotcrete can be significantly influenced by the inclusion of melt extract stainless steel fibers. To begin with, the incorporation of stainless steel fibers can enhance the viscosity and fluidity of the shotcrete mixture. These fibers act as reinforcements and aid in maintaining the stability and flow of the mixture, preventing segregation and settlement during application. This is especially crucial in self-compacting shotcrete, where achieving a high level of workability is necessary for proper consolidation and filling of desired areas. Furthermore, the stainless steel fibers also improve the cohesion and cohesiveness of the shotcrete mixture. Serving as bonding agents, these fibers enhance the interactions between particles, thereby increasing the strength and durability of the shotcrete. As a result, the material becomes more cohesive and stable, reducing the likelihood of cracking and shrinkage. Moreover, the presence of stainless steel fibers can also influence the setting time of the shotcrete. These fibers can expedite the hydration process and promote early strength development. This is advantageous in self-compacting shotcrete applications that require rapid setting and early strength to facilitate faster construction progress. In addition, the melt extract stainless steel fibers contribute to the overall ductility and toughness of the shotcrete. They offer additional resistance against crack propagation and enhance the structural integrity of the material. This is particularly important in self-compacting shotcrete as it improves performance under dynamic loading conditions and enhances the material's ability to withstand external forces. Overall, the inclusion of melt extract stainless steel fibers positively impacts the rheology of self-compacting shotcrete by enhancing viscosity, cohesion, setting time, and overall durability. Their addition improves the workability and performance of the shotcrete, making it highly suitable for various construction applications.

- Q: Can melt extract stainless steel fiber be used in bridge deck overlays for asphalt mixtures?

- Yes, melt extract stainless steel fiber can be used in bridge deck overlays for asphalt mixtures. Its high tensile strength and resistance to corrosion make it suitable for reinforcing asphalt overlays, improving their durability and preventing cracking.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 200 Million |

| Main Markets | North America;Asia;Western Europe;Africa;Russia;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Installation guide, OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Melt Extract Stainless Steel Fiber 446 - High Quality Melt Extract Stainless Steel Fiber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords