Melt Extract Stainless Steel Fiber - Straight Type from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

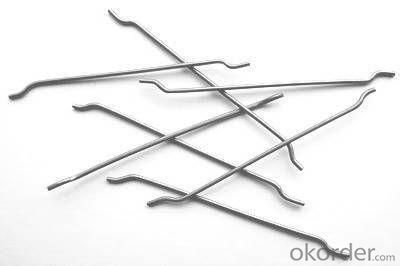

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: How does melt extract stainless steel fiber contribute to the crack control of concrete?

- Melt extract stainless steel fiber enhances the crack control of concrete by acting as reinforcement within the material. The fibers are uniformly distributed throughout the concrete matrix, creating a three-dimensional network that helps to distribute loads and inhibit the propagation of cracks. This reinforcement improves the overall tensile strength and ductility of the concrete, reducing the formation and widening of cracks. Additionally, the stainless steel fibers can effectively bridge small cracks, preventing them from developing into larger, more significant cracks.

- Q: Can melt extract stainless steel fiber be used in precast concrete products?

- Precast concrete products can indeed benefit from the utilization of melt extract stainless steel fiber. Such fibers are a reinforcement material that can be incorporated into concrete mixes for the purpose of enhancing their strength and durability. By improving the concrete's tensile strength and resistance to cracking, melt extract stainless steel fiber enables its suitability for various applications, including precast concrete products. During the batching process, the stainless steel fibers are typically blended into the concrete mixture and evenly dispersed throughout. This reinforcement proves especially advantageous for precast concrete products subjected to substantial loads or harsh environmental conditions. The inclusion of melt extract stainless steel fiber effectively prevents cracking and extends the overall lifespan of the precast concrete product.

- Q: What is the recommended mix design for concrete containing melt extract stainless steel fiber?

- The recommended mix design for concrete containing melt extract stainless steel fiber typically involves using a higher dosage of fibers compared to traditional concrete mix designs. This is because stainless steel fibers have a higher aspect ratio and better tensile strength, which allows for better reinforcement and crack resistance in the concrete. The fiber dosage can vary depending on the specific application and desired performance characteristics of the concrete. However, a general guideline is to use between 1% to 2% by volume of stainless steel fibers. This dosage range has been found to provide optimal reinforcement and improve the overall durability of the concrete. In addition to the fiber dosage, it is important to consider other factors such as the water-cement ratio, aggregate gradation, and admixture selection. The water-cement ratio should be carefully controlled to ensure the mix is workable and has adequate strength. The aggregate gradation should be optimized to provide a dense and strong concrete matrix. Admixtures can also be used to improve the workability, pumpability, and setting time of the concrete. It is recommended to consult with a qualified engineer or concrete supplier to determine the specific mix design parameters for a project involving melt extract stainless steel fiber. Overall, the recommended mix design for concrete containing melt extract stainless steel fiber involves a higher fiber dosage, careful control of water-cement ratio, optimization of aggregate gradation, and appropriate use of admixtures. This will help ensure a high-performance concrete with improved reinforcement and durability properties.

- Q: What is the effect of melt extract stainless steel fiber on the flexural toughness of concrete?

- The addition of melt extract stainless steel fiber to concrete has a positive effect on the flexural toughness of the material. The fibers act as reinforcement, increasing the overall strength and resistance to cracking or failure under bending or flexural forces. This leads to improved durability and increased load-bearing capacity of the concrete, making it more suitable for applications where flexural strength is crucial.

- Q: What is the role of melt extract stainless steel fiber in refractory materials?

- The role of melt extract stainless steel fiber in refractory materials is primarily to enhance the mechanical properties and performance of the refractory material. Stainless steel fibers are added to the refractory mix to provide reinforcement and improve its resistance to thermal shock, cracking, and mechanical stress. The melt extract process ensures that the stainless steel fibers have a high degree of purity and uniformity, making them suitable for use in high-temperature applications. These fibers are typically added in small quantities to the refractory mix, but they significantly improve its strength, toughness, and resistance to wear and erosion. Stainless steel fibers also enhance the refractory material's thermal conductivity and dimensional stability, allowing it to withstand extreme temperatures without significant deformation or deterioration. They act as a reinforcement network within the refractory matrix, preventing the propagation of cracks and enhancing its overall durability. Furthermore, stainless steel fibers can improve the refractory material's resistance to chemical attack and corrosion, making it suitable for use in aggressive environments. They can also enhance the refractory's ability to retain heat, improving energy efficiency in various industrial applications. Overall, the addition of melt extract stainless steel fibers in refractory materials significantly enhances their mechanical strength, thermal stability, and resistance to various forms of degradation. This allows refractory materials to withstand harsh operating conditions and prolong their service life, making them essential in industries such as steelmaking, cement production, glass manufacturing, and petrochemical processing.

- Q: Can melt extract stainless steel fiber be used in pedestrian walkway pavements?

- Melt extract stainless steel fiber is a suitable option for pedestrian walkway pavements. Concrete mixtures are frequently enriched with stainless steel fibers to enhance their mechanical properties and overall performance. By incorporating stainless steel fibers, the concrete's tensile strength and resistance to cracking are increased, resulting in improved durability and suitability for high-traffic areas such as pedestrian walkways. Moreover, the utilization of stainless steel fibers offers better corrosion resistance and aids in preventing crack formation due to temperature fluctuations or shrinkage. Consequently, melt extract stainless steel fiber is an exceptional choice for reinforcing pedestrian walkway pavements, guaranteeing their longevity and safety.

- Q: What is the effect of melt extract stainless steel fiber on the permeability of concrete?

- The permeability of concrete is primarily decreased by the presence of melt extract stainless steel fiber. Once these fibers are incorporated into the concrete, they establish an interconnected network, thereby boosting its overall resilience and strength. The stainless steel fibers in concrete serve as a barrier against the movement of liquid, including water. This barrier effectively lowers the permeability of the concrete, rendering it less susceptible to water absorption, moisture infiltration, and subsequent harm caused by freezing and thawing or chemical attacks. Furthermore, the usage of melt extract stainless steel fibers in concrete helps diminish crack formation and shrinkage. These fibers reinforce the concrete and hinder crack propagation, thereby enhancing the structural integrity of the material as a whole. Consequently, this contributes to a reduction in permeability. Additionally, the stainless steel fibers also enhance the bond between the concrete and other materials, such as aggregates or reinforcement bars. This improved bond further decreases the permeability of the concrete by minimizing the potential for water to permeate through gaps or weak points in the structure. In conclusion, the inclusion of melt extract stainless steel fiber in concrete has a positive impact on its permeability. It lessens water absorption, diminishes crack formation, and improves the overall durability and strength of the material. Ultimately, this leads to improved performance and longevity of concrete structures.

- Q: How does melt extract stainless steel fiber improve the durability of sprayed concrete?

- The durability of sprayed concrete is significantly enhanced by melt extract stainless steel fiber. These fibers play a vital role in reinforcing the concrete matrix, effectively boosting its tensile strength and resistance to cracking. This is especially important in high-pressure application techniques used in sprayed concrete, as it is prone to shrinkage and cracking. Furthermore, stainless steel fibers possess unique properties, such as high corrosion resistance, which safeguard the concrete from environmental factors that can deteriorate its durability. They are highly resistant to rust and other forms of corrosion, offering particular advantages in harsh or corrosive surroundings. Additionally, the presence of these fibers improves the impact resistance of sprayed concrete. Due to their strength and flexibility, they can absorb and distribute energy when subjected to impact or dynamic loads, decreasing the risk of surface spalling or cracking. Moreover, melt extract stainless steel fibers enhance the overall cohesion and bond strength between the sprayed concrete and the substrate. This is crucial in sprayed concrete applications, ensuring a robust connection between the concrete and the applied surface, minimizing the risk of delamination or detachment. In conclusion, melt extract stainless steel fiber enhances the durability of sprayed concrete by improving its tensile strength, resistance to cracking, impact resistance, corrosion resistance, and overall bond strength. These fibers provide essential reinforcement to the concrete matrix, making it more resilient and extending its service life in a variety of challenging environments and applications.

- Q: What is the typical length of melt extract stainless steel fiber?

- The typical length of melt extract stainless steel fiber is usually between 20 to 50 millimeters.

- Q: What is the effect of melt extract stainless steel fiber on the ductility of concrete?

- The ductility of concrete can be positively influenced by adding melt extract stainless steel fiber. Stainless steel fibers are renowned for their high tensile strength and exceptional resistance to corrosion, which can enhance the overall performance of concrete. By incorporating stainless steel fibers into concrete, they serve as reinforcement, imparting additional strength and stability to the material. This reinforcement aids in the even distribution of stress and load throughout the concrete, reducing the likelihood of cracking and increasing its ductility. Concrete infused with melt extract stainless steel fiber exhibits improved flexural strength, toughness, and resistance to impact and fatigue. These fibers create a network within the concrete matrix, effectively bridging cracks and preventing their propagation. This bridging effect heightens the overall ductility of the concrete, enabling it to endure greater deformation and uphold its structural integrity in various loading conditions. Moreover, the corrosion resistance of stainless steel fibers ensures that their mechanical properties endure over time. This long-lasting durability contributes to the sustained ductility of the concrete, even when subjected to harsh environmental conditions or aggressive chemicals. In summary, the addition of melt extract stainless steel fiber to concrete significantly enhances its ductility by providing reinforcement, enhancing crack resistance, and guaranteeing long-term durability. This advancement in ductility enables the concrete to better withstand external forces and maintain its structural integrity, making it a valuable inclusion in construction projects that necessitate high-performance and long-lasting concrete structures.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords