Melt Extract Stainless Steel Fiber Reinforced Wavy Shear-Cut Concrete Admixtures

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland)

Model Number: steel fiber

material: steel wire

application: concrete reinocement

type: end hook steel fiber

Product features

Steel band shearing type steel fiber

Good quality, low price, high cost performance

Product overview

1, through the ISO9001 certification

More than

2, Material: low carbon steel strip

3. Shape: Wave

4. Multi anchorage points, rolling force is good

5. good quality, low price, high cost performance

wavy steel fiber

1, the length of 15 - 50 mm

2, the diameter of 0.5-1.2 mm

3, the intensity is 380-600 mpa

Specifications

1.hooked steel fiber

2.CE and ISO9001:2008

3.diameter from 0.5mm to 1.2mm

4.competitive price,high quality and service

Hooked Steel Fiber:

1.Diameter:0.5mm-1.0mm

2.Length: 25mm-60mm

3.Material: low carbon steel wire

4.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

5.Uses: high way,tunnel,building,airport road serface and so on .

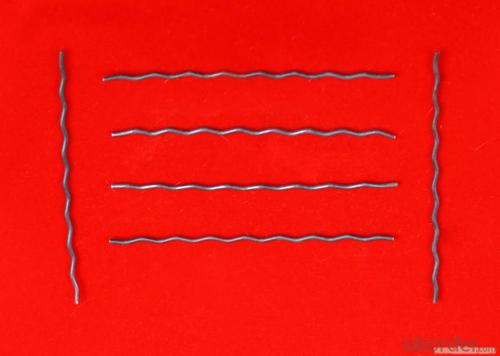

Picture

steel fiber concrete reinforced

FAQ

we can produce any type steel fiber and of course we can make production according to your requirement

we have specilize in this field for almost 10 years ,with good quality and competitive price

- Q: Can melt extract stainless steel fiber be used in elevated slabs?

- Yes, melt extract stainless steel fiber can be used in elevated slabs. These fibers provide enhanced strength and durability to the concrete, making it suitable for use in elevated slabs where additional reinforcement is required.

- Q: Can melt extract stainless steel fiber be used in high-temperature refractory applications?

- Yes, melt extract stainless steel fiber can be used in high-temperature refractory applications. This type of fiber is specifically designed to withstand extreme temperatures and maintain its structural integrity in high-heat environments. It is commonly used in refractory materials such as castable refractories, ceramic fiber products, and other high-temperature insulation applications. The melt extract stainless steel fiber offers excellent heat resistance, corrosion resistance, and mechanical strength, making it suitable for use in various refractory applications where high temperatures are encountered.

- Q: What is the cost-effectiveness of using melt extract stainless steel fiber in concrete?

- The cost-effectiveness of using melt extract stainless steel fiber in concrete can be quite high. While the initial cost of incorporating stainless steel fibers may be higher compared to traditional reinforcement methods, the long-term benefits outweigh the expenses. Stainless steel fibers improve the durability, strength, and crack resistance of concrete structures, reducing the need for frequent repairs and maintenance. This results in cost savings over the lifespan of the structure, making it a cost-effective choice in the long run. Additionally, the use of stainless steel fibers can enhance the overall performance and lifespan of the concrete, making it a reliable and efficient construction material.

- Q: What are the properties of melt extract stainless steel fiber?

- Melt extract stainless steel fiber is a type of fiber that is formed through the extraction process of molten stainless steel. It possesses several properties such as high temperature resistance, excellent corrosion resistance, good mechanical strength, high electrical conductivity, and thermal conductivity. Additionally, it has a long lifespan, is non-magnetic, and can be easily blended with other materials, making it suitable for various applications in industries like construction, automotive, textiles, and electronics.

- Q: How does melt extract stainless steel fiber affect the crack width of concrete?

- Melt extract stainless steel fiber plays a significant role in reducing the crack width of concrete. When added to the concrete mix, these fibers act as reinforcement, enhancing the overall strength and durability of the material. The fibers are uniformly distributed within the concrete matrix, creating a three-dimensional network that helps to control cracking. The primary mechanism through which melt extract stainless steel fibers reduce crack width is by mitigating the propagation of cracks. As concrete undergoes shrinkage and thermal expansion/contraction, micro-cracks can form. However, the presence of stainless steel fibers acts as a barrier to crack growth, preventing the cracks from enlarging and spreading throughout the concrete. Furthermore, the unique properties of stainless steel contribute to its effectiveness in reducing crack width. Stainless steel fibers have high tensile strength, which enables them to withstand significant loads and resist deformation. This strength allows the fibers to bridge across cracks, providing additional reinforcement to the concrete and preventing further crack propagation. Additionally, the aspect ratio of the fibers (length to diameter ratio) also plays a role in controlling crack width. Longer fibers tend to be more effective in limiting crack propagation compared to shorter fibers. Therefore, choosing the appropriate aspect ratio of melt extract stainless steel fibers is essential to achieve the desired crack control in concrete. In summary, melt extract stainless steel fibers positively impact the crack width of concrete by minimizing crack propagation. Through their reinforcement properties and ability to bridge across cracks, these fibers enhance the overall structural integrity of concrete, resulting in reduced crack width and improved durability.

- Q: Does melt extract stainless steel fiber improve the resistance to efflorescence in concrete?

- Yes, melt extract stainless steel fiber can improve the resistance to efflorescence in concrete.

- Q: What is the difference between melt extract stainless steel fiber and other types of steel fibers?

- Melt extracted stainless steel fiber, also referred to as melt extract steel fiber, is produced by melting stainless steel and then swiftly drawing it into fine fibers. This manufacturing process yields fibers with distinct properties and characteristics compared to alternative steel fibers. An important distinction of melt extract stainless steel fiber from other varieties is its improved resistance to corrosion. Stainless steel is renowned for its capacity to withstand corrosion and oxidation, rendering melt extract stainless steel fibers highly impervious to rust and degradation over time. Consequently, they are suitable for use in environments prone to exposure to moisture, chemicals, or other corrosive substances. Another distinction lies in the heightened tensile strength of melt extract stainless steel fibers. The expedited extraction process aligns the steel molecules, resulting in fibers that are more robust and durable than their counterparts. This augmented tensile strength makes melt extract stainless steel fibers optimal for reinforcing concrete or other materials that necessitate high strength and durability. Additionally, melt extract stainless steel fibers exhibit exceptional thermal and electrical conductivity. This attribute makes them suitable for applications requiring efficient heat or electricity transfer. For instance, they can be employed in heating elements, electromagnetic shielding, or as conductive reinforcement in composites. Lastly, melt extract stainless steel fibers possess a smoother surface compared to other steel fibers. This smooth surface promotes improved bonding with the surrounding matrix, such as concrete or resin, leading to enhanced load transfer and overall performance. Furthermore, the smoothness reduces the likelihood of fiber pull-out or breakage, further enhancing their effectiveness as reinforcement materials. In conclusion, melt extract stainless steel fibers distinguish themselves from alternative steel fibers due to their enhanced corrosion resistance, increased tensile strength, exceptional thermal and electrical conductivity, and smoother surface. These distinctive properties render them a preferred choice for various applications requiring high-performance reinforcement materials.

- Q: How does melt extract stainless steel fiber improve the resistance to chemical attack in concrete?

- Melt extract stainless steel fiber is known for enhancing the resistance to chemical attack in concrete due to its unique properties and characteristics. When added to concrete mixtures, the stainless steel fibers act as a reinforcement that improves the durability and longevity of the concrete structure. One of the primary ways in which melt extract stainless steel fiber improves the resistance to chemical attack is by forming a physical barrier against corrosive substances. Concrete is generally susceptible to chemical attack from substances such as acids, alkalis, and chlorides, which can penetrate the concrete matrix and cause deterioration over time. However, the addition of stainless steel fibers creates a network of reinforcement within the concrete, which acts as a protective barrier against chemical intrusion. This, in turn, reduces the permeability of the concrete and prevents the corrosive substances from reaching and damaging the underlying steel reinforcement. Furthermore, melt extract stainless steel fiber also enhances the resistance to chemical attack by improving the mechanical properties of the concrete. The addition of stainless steel fibers increases the flexural strength, tensile strength, and impact resistance of the concrete, making it more resistant to cracking and spalling caused by chemical exposure. This improved mechanical performance helps to maintain the integrity of the concrete structure and prevents the ingress of corrosive substances through cracks and fissures. Moreover, stainless steel fibers also play a crucial role in minimizing the effects of chemical attack by reducing the formation of microcracks in the concrete. Chemical attack can lead to the formation of cracks and fractures in the concrete, which can further accelerate the deterioration process. However, the presence of stainless steel fibers helps to distribute the stress and load more evenly throughout the concrete, preventing the concentration of forces that can lead to crack formation. By minimizing the formation of microcracks, the stainless steel fibers effectively reduce the vulnerability of the concrete to chemical attack and enhance its overall durability. In conclusion, melt extract stainless steel fiber improves the resistance to chemical attack in concrete by forming a physical barrier against corrosive substances, enhancing the mechanical properties of the concrete, and minimizing the formation of microcracks. These combined effects result in a more durable and long-lasting concrete structure that is better able to withstand the detrimental effects of chemical exposure.

- Q: What is the effect of melt extract stainless steel fiber on the shrinkage of concrete?

- The effect of melt extract stainless steel fiber on the shrinkage of concrete can be significant. Stainless steel fibers, when added to concrete, act as reinforcement and help to reduce shrinkage. Shrinkage in concrete occurs due to the loss of moisture during the curing process, which can lead to cracking and reduced durability. By incorporating melt extract stainless steel fibers into the concrete mix, the fibers create a network of reinforcement throughout the material. This reinforcement helps to distribute and control the shrinkage forces, resulting in reduced overall shrinkage and improved crack resistance. The presence of stainless steel fibers also enhances the tensile strength of the concrete, which further contributes to its resistance to shrinkage. The fibers act as tiny reinforcements, bridging any cracks that may occur and preventing them from propagating, thereby minimizing shrinkage-induced cracking. Additionally, the high corrosion resistance of stainless steel fibers ensures their long-term functionality in concrete. This is particularly important in environments with high moisture or chloride exposure, where conventional steel reinforcement may corrode over time, leading to increased shrinkage and reduced structural integrity. In summary, the incorporation of melt extract stainless steel fibers in concrete can effectively mitigate shrinkage by providing reinforcement, improving crack resistance, and enhancing overall durability. This leads to a more stable and long-lasting concrete structure.

- Q: How does melt extract stainless steel fiber impact the shrinkage cracking of concrete pavements?

- The reduction of shrinkage cracking in concrete pavements can be significantly influenced by the utilization of melt extract stainless steel fiber. Cracks are formed when the concrete undergoes volume reduction due to drying and thermal shrinkage. By incorporating melt extract stainless steel fiber into the concrete mixture, the overall tensile strength and ductility of the concrete are enhanced. These fibers function as reinforcement, effectively distributing stress and preventing crack formation and propagation. Moreover, they aid in controlling plastic shrinkage by reducing the rate of water evaporation from the concrete surface. The stainless steel fibers are uniformly dispersed throughout the concrete matrix, forming a three-dimensional reinforcement system. This reinforcement enhances the concrete's ability to withstand shrinkage stresses, thus decreasing the likelihood of shrinkage cracking. Furthermore, the use of melt extract stainless steel fiber can augment the durability and lifespan of concrete pavements. It heightens the concrete's resistance to abrasion, impact, and fatigue, rendering it more resilient against the strains and pressures exerted by traffic loads. In summary, melt extract stainless steel fiber plays a beneficial role in mitigating shrinkage cracking in concrete pavements. It enhances the concrete's tensile strength, ductility, and resistance to shrinkage stresses, thereby reducing the occurrence of cracks. Additionally, the incorporation of these fibers improves the longevity and reliability of concrete pavements, making them more durable and long-lasting.

Send your message to us

Melt Extract Stainless Steel Fiber Reinforced Wavy Shear-Cut Concrete Admixtures

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords