Melt Extract Stainless Steel Fiber Loose Company from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Place of Origin: China (Mainland)

Model Number: HT-MC

Material: Color Steel

certificated: ISO 9001

Specifications

| Product | Diameter | Length mm/in | Aspect Ratio | Type | Packing |

| G-6030 | 0.5 mm (0.0197 in) | 30 mm (1.1811 in) | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 mm (0.0217 in) | 35 mm (1.3780 in) | 65 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 mm (0.0236 in) | 35 mm (1.3780 in) | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 mm (0.0295 in) | 60 mm (2.3622 in) | 80 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 mm (0.0354 in) | 60 mm (2.3622 in) | 60 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6030 | 0.5 mm (0.0197 in) | 30 mm (1.1811 in) | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 mm (0.0217 in) | 35 mm (1.3780 in) | 65 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 mm (0.0236 in) | 35 mm (1.3780 in) | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 mm (0.0295 in) | 60 mm (2.3622 in) | 80 | Loose | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 mm (0.0354 in) | 60 mm (2.3622 in) | 60 | Loose | 20 kg/Bag, 50 bags/Pallet |

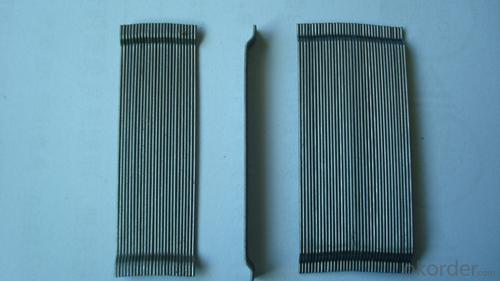

Picture

steel fiber

FAQ

1) Material: low carbon steel wire

2) Diameter: 0.4mm

3) Length: 18mm-35mm

4) Tensile strength: >1000Mpa

5) Feature: excellent tensile, high tenacity, against cracking, impact and fatigue

6) Uses: highway road surface, tunnel, building, airport road surface and so on.

- Q: Does melt extract stainless steel fiber enhance the flexural strength of concrete?

- Yes, melt extract stainless steel fiber does enhance the flexural strength of concrete.

- Q: Does melt extract stainless steel fiber improve the resistance to impact of shotcrete?

- Yes, melt extract stainless steel fiber does improve the resistance to impact of shotcrete.

- Q: Are there any guidelines or standards for using melt extract stainless steel fiber in construction?

- Yes, there are guidelines and standards for using melt extract stainless steel fiber in construction. These guidelines provide recommendations for the appropriate dosage, distribution, and mixing of the fiber in concrete or mortar, as well as guidance on the design and construction of fiber-reinforced concrete structures. Additionally, there are standards that specify the mechanical properties, dimensions, and testing requirements for melt extract stainless steel fibers used in construction applications. Following these guidelines and standards ensures the safe and effective use of melt extract stainless steel fiber in construction projects.

- Q: Can melt extract stainless steel fiber be used in lightweight concrete wall panels?

- Yes, melt extract stainless steel fiber can be used in lightweight concrete wall panels. The stainless steel fibers improve the strength and durability of the concrete, making it suitable for use in wall panels while still maintaining a lightweight structure.

- Q: What is the typical length and diameter of melt extract stainless steel fiber?

- The size of melt extract stainless steel fiber may vary depending on the specific application and requirements. However, generally speaking, there is a range of lengths and diameters available for melt extract stainless steel fibers. Melt extract stainless steel fiber can have a length ranging from a few millimeters to several centimeters. Shorter fibers are typically used for reinforcing composites, while longer fibers are commonly used for filtration and thermal insulation purposes. The diameter of melt extract stainless steel fiber can also vary, ranging from a few micrometers to a few millimeters. Thinner fibers are often used in applications that require a high surface area to volume ratio, such as conductive textiles or electromagnetic shielding. Thicker fibers, on the other hand, are commonly employed for applications that require greater mechanical strength or thermal conductivity, like reinforcing concrete or heat transfer components. It's important to note that the specific length and diameter of melt extract stainless steel fiber will depend on the desired properties and performance requirements of the application. Manufacturers and suppliers can provide more precise information on the available options and assist in selecting the most suitable fiber dimensions for a particular application.

- Q: Does melt extract stainless steel fiber improve the resistance to chloride ingress in shotcrete?

- Yes, melt extract stainless steel fiber does improve the resistance to chloride ingress in shotcrete. Chloride ions are known to cause corrosion in concrete structures, especially in marine environments or areas with high exposure to chloride salts. By incorporating melt extract stainless steel fibers into shotcrete mixtures, the concrete can have enhanced durability and resistance against chloride penetration. Melt extract stainless steel fibers are specifically engineered to provide reinforcement in concrete and shotcrete applications. These fibers are made from high-quality stainless steel and have excellent corrosion resistance properties. When added to shotcrete mixtures, the stainless steel fibers form a three-dimensional network within the concrete matrix, which helps to distribute stress and prevent crack formation. In terms of chloride ingress resistance, the presence of melt extract stainless steel fibers acts as a physical barrier that restricts the movement of chloride ions into the concrete. The fibers create a tortuous path for the chloride ions to follow, thereby slowing down their penetration rate. This significantly reduces the risk of corrosion initiation and propagation within the concrete. Furthermore, melt extract stainless steel fibers also improve the overall durability of shotcrete by increasing its resistance to freeze-thaw cycles, abrasion, impact, and other forms of deterioration. This extended service life further contributes to the enhanced resistance to chloride ingress, as the concrete remains structurally sound and less susceptible to chloride-induced corrosion. It is important to note that while melt extract stainless steel fibers provide significant benefits in terms of chloride ingress resistance, they should be used in conjunction with other corrosion mitigation measures, such as proper concrete cover, waterproofing systems, and appropriate concrete mix design. Additionally, the dosage and distribution of the stainless steel fibers within the shotcrete mixture should be carefully determined based on the specific project requirements and exposure conditions.

- Q: Can melt extract stainless steel fiber be used in dam construction applications?

- Yes, melt extract stainless steel fiber can be used in dam construction applications. It is commonly used to reinforce concrete structures, including dams, due to its high tensile strength and corrosion resistance. The fiber helps improve the overall durability and strength of the concrete, making it suitable for use in dam construction where structural integrity is crucial.

- Q: How does melt extract stainless steel fiber improve the resistance to aging in asphalt mixtures?

- The resistance to aging in asphalt mixtures is improved by melt extract stainless steel fiber in various ways. Firstly, the overall strength and durability of the asphalt mixture are enhanced by adding stainless steel fiber. This increased strength enables the pavement to withstand repetitive loads and traffic stresses, reducing the likelihood of premature cracking, rutting, or other forms of distress. Moreover, stainless steel fiber acts as a reinforcement within the asphalt matrix, preventing crack propagation and reducing aging-related damage. These fibers create a three-dimensional network that distributes stress more evenly throughout the mixture, minimizing stress concentration at specific points and increasing resistance to deformation. Additionally, the presence of stainless steel fiber improves resistance to temperature variations in asphalt mixtures. It helps mitigate the effects of thermal expansion and contraction, reducing the risk of thermal cracking and enhancing long-term pavement performance. Furthermore, stainless steel fiber exhibits excellent corrosion resistance properties. This means that even in harsh environmental conditions, such as moisture or exposure to deicing salts, the fibers will not corrode or degrade over time. This corrosion resistance greatly contributes to improved aging resistance, as it ensures the reinforcing effect of the fibers remains intact throughout the lifespan of the asphalt pavement. In conclusion, melt extract stainless steel fiber enhances resistance to aging in asphalt mixtures by improving overall strength and durability, preventing crack propagation, reducing deformation, mitigating thermal cracking, and providing excellent corrosion resistance. These advantages result in a longer lifespan and improved performance of the asphalt pavement, ultimately saving costs and enhancing the safety and comfort of road users.

- Q: Can melt extract stainless steel fiber be used in high-temperature applications?

- Certainly, the utilization of melt extract stainless steel fiber is applicable in high-temperature scenarios. This particular variant of stainless steel fiber is engineered specifically to endure extreme levels of heat and is typically employed within industries such as aerospace, automotive, and construction, where elevated temperatures are prevalent. The melt extract procedure guarantees that the stainless steel fiber possesses remarkable thermal stability, enabling it to preserve its structural integrity even when subjected to heightened temperatures. Furthermore, stainless steel is renowned for its ability to resist oxidation and corrosion, rendering it suitable for extended periods of exposure to high temperatures without any deterioration. In summary, melt extract stainless steel fiber represents an optimal selection for high-temperature applications due to its enduring nature, heat resistance, and resistance to oxidation.

- Q: What is the effect of melt extract stainless steel fiber on the crack propagation in concrete?

- The primary effect of melt extract stainless steel fiber on crack propagation in concrete is to enhance crack resistance and improve the overall durability of concrete structures. When stainless steel fibers are incorporated into concrete, they create a three-dimensional reinforcement network that promotes a more even distribution of stress throughout the concrete matrix. By dispersing the load and reducing stress concentration at vulnerable points like cracks or weak zones, the stainless steel fibers effectively hinder crack propagation. Acting as micro-reinforcements within the concrete, these fibers bridge cracks and prevent them from spreading further. Stainless steel fibers possess unique properties such as high tensile strength, corrosion resistance, and ductility, which make them particularly effective in boosting concrete's crack resistance. Unlike other fiber types, stainless steel fibers can withstand high tensile stresses and maintain their integrity even in extreme conditions like freeze-thaw cycles or exposure to chemicals. Moreover, the manufacturing process of melt extract stainless steel fibers ensures a high aspect ratio, providing a large surface area for interaction with the surrounding concrete matrix. This increased bond between the fibers and the concrete matrix further enhances crack resistance. Overall, the inclusion of melt extract stainless steel fibers in concrete significantly improves its ability to resist cracking and enhances its durability. Consequently, this leads to extended service life, reduced maintenance expenses, and enhanced safety for concrete structures in various applications such as buildings, bridges, pavements, and tunnels.

Send your message to us

Melt Extract Stainless Steel Fiber Loose Company from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords