Melt Extract Stainless Steel Fiber - Glued Hooked-End Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Place of Origin: Tianjin, China (Mainland)

Model Number: 0.9

Material: Steel

Production Process: Cold drawn

Lengh: 55

Type: 1

Compressive Strength: >1200MPa

Aspect ratio: 61

Standard: ASTM A820M-11

Section Shape: Circular

Application: Concrete Reinforcement

Packaging & Delivery

| Packaging Details: | 20 kg/Bag,50 bags/Pallet or 1,000kg/ Bulk Bag |

|---|---|

| Delivery Detail: | 1 Month |

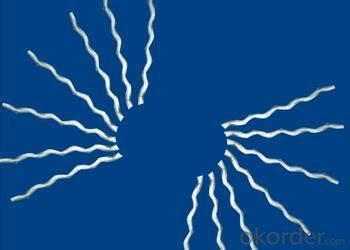

Product Description

| Diameter | 0.90 | mm | 0.04 | in |

| Length | 55.00 | mm | 2.16 | in |

| Aspect Ratio | 61 | |||

| Tensile strength | 1200 MPa | |||

| Type | Cold drawn Steel Fiber | |||

| End | Hooked-end Steel Fiber | |||

| Glued/Loose | Glued Steel Fiber | |||

| Bending Angle | 45°(min.30°) | |||

| Usage & Performance | Floor:Trafficked areas and Industrial floors | |||

| Shotcrete :Slope stabilization and Final lining | ||||

| Precast concrete:Pipe and Railway sleepers | ||||

| Packing | Standard Export Pallet Packing | Bag Packing | 20 kg/Bag,50 bags/Pallet | |

| Bulk Packing | 1,000kg/ Bulk Bag | |||

| Loading Quantity | 20’GP | 20-25 Tonne/Tonnes | ||

| 40’GP | 25-27 Tonne/Tonnes | |||

| 40’HQ | 25-27 Tonne/Tonnes | |||

| MOQ | 1 kg for trial order | |||

| Supply Ability | 10,000 Tonne/Tonnes per Year | |||

| Payment Terms | T/T or L/C at sight | |||

| Delivery Time | Within 15 days after receiving deposit or original L/C at sight | |||

| Certification | ISO9001:2000, CE, | |||

| Product | Diameter | Length mm/in | Aspect Ratio | Type | Packing |

| G-6030 | 0.5 mm (0.0197 in) | 30 mm (1.1811 in) | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 mm (0.0217 in) | 35 mm (1.3780 in) | 65 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 mm (0.0236 in) | 35 mm (1.3780 in) | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 mm (0.0295 in) | 60 mm (2.3622 in) | 80 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 mm (0.0354 in) | 60 mm (2.3622 in) | 60 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6030 | 0.5 mm (0.0197 in) | 30 mm (1.1811 in) | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 mm (0.0217 in) | 35 mm (1.3780 in) | 65 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 mm (0.0236 in) | 35 mm (1.3780 in) | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 mm (0.0295 in) | 60 mm (2.3622 in) | 80 | Loose | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 mm (0.0354 in) | 60 mm (2.3622 in) | 60 | Loose | 20 kg/Bag, 50 bags/Pallet |

- Q: Are there any limitations or precautions to consider when using melt extract stainless steel fiber?

- When using melt extract stainless steel fiber, there are certain limitations and precautions that need to be taken into account. To begin with, it should be noted that this type of fiber is not suitable for high-temperature applications. Its melting point is relatively low compared to other stainless steel alloys, meaning it may not be able to withstand extremely high temperatures without deforming or losing its structural integrity. Therefore, it is crucial to determine the maximum temperature the fiber can handle and avoid exposing it to temperatures beyond this limit. Another factor to consider is the possibility of corrosion. Although stainless steel is generally resistant to corrosion, certain environmental conditions, such as exposure to acids or chlorides, can still lead to corrosion. It is advisable to evaluate the specific corrosive agents present in the application environment and choose a stainless steel fiber grade that offers appropriate corrosion resistance. Additionally, proper handling and installation of the melt extract stainless steel fiber is important. The fibers can be sharp and pose a risk of injury if not handled correctly. It is recommended to wear gloves and other protective equipment while handling them to minimize the risk of cuts or abrasions. Furthermore, achieving the desired performance of the stainless steel fibers within a matrix material, such as concrete or composite, depends on their dispersion. It is necessary to ensure that the fibers are mixed and distributed properly to avoid clumping or agglomeration, which can result in uneven reinforcement and compromised mechanical properties. Lastly, the cost of melt extract stainless steel fiber should be taken into consideration. Compared to other options for fiber reinforcement, such as synthetic fibers or traditional steel rebars, stainless steel fiber can be more expensive. Therefore, it is important to assess the project budget and weigh the benefits of using stainless steel fiber against its higher cost. In conclusion, while melt extract stainless steel fiber offers several advantages, it is essential to be aware of its limitations and take necessary precautions. Understanding the temperature limits, potential for corrosion, handling requirements, dispersion considerations, and cost implications will help ensure the successful and safe use of this reinforcement material.

- Q: What is the effect of melt extract stainless steel fiber on the workability of asphalt mixtures?

- The effect of melt extract stainless steel fiber on the workability of asphalt mixtures is that it improves the overall workability and stability of the mixture. The stainless steel fibers act as a reinforcement, enhancing the cohesive properties of the asphalt and reducing the risk of cracking and rutting. This results in a more durable and long-lasting asphalt pavement that can withstand heavy traffic loads and extreme weather conditions.

- Q: How does melt extract stainless steel fiber improve the toughness of concrete?

- Melt extract stainless steel fiber improves the toughness of concrete by enhancing its crack resistance and durability. The steel fibers act as reinforcement within the concrete matrix, distributing and absorbing stress and preventing the propagation of cracks. This improves the overall strength and longevity of the concrete, making it more resistant to impact, flexural, and fatigue loads.

- Q: What are the advantages of using melt extract stainless steel fiber in shotcrete applications?

- Using melt extract stainless steel fiber in shotcrete applications offers several advantages: 1. Enhanced durability: Stainless steel fibers have excellent corrosion resistance, making them ideal for shotcrete applications in harsh environments or structures exposed to moisture, chemicals, or high temperatures. This durability ensures the longevity and structural integrity of the shotcrete. 2. Improved crack resistance: Stainless steel fibers enhance the crack resistance and toughness of shotcrete. They distribute stress more evenly throughout the material, reducing the likelihood of cracks forming and propagating. This helps to prevent water infiltration, reinforcing the shotcrete and increasing its overall strength. 3. Increased flexural strength: The addition of stainless steel fibers in shotcrete improves its flexural strength. This reinforcement allows for greater resistance to bending or deflection, making the shotcrete more resilient under various loads or structural movements. 4. Enhanced impact resistance: Stainless steel fibers enhance the impact resistance of shotcrete, making it more resistant to external forces such as impact or vibrations. This advantage is particularly beneficial in shotcrete applications where structures may be exposed to heavy traffic, seismic activity, or significant dynamic loads. 5. Ease of application: Melt extract stainless steel fibers are easily incorporated into shotcrete mixtures, as they can be uniformly distributed throughout the material during the mixing process. This ease of application contributes to time and cost savings during construction. Overall, using melt extract stainless steel fiber in shotcrete applications provides numerous advantages, including enhanced durability, improved crack resistance, increased flexural strength, enhanced impact resistance, and ease of application.

- Q: How does melt extract stainless steel fiber improve the durability of tunnel linings?

- Melt extract stainless steel fiber improves the durability of tunnel linings by providing enhanced reinforcement and resistance to various forms of deterioration. When added to the concrete mixture used for tunnel linings, these stainless steel fibers act as micro-reinforcement, enhancing the overall strength and durability of the structure. One key benefit of melt extract stainless steel fiber is its ability to enhance the tensile strength of the concrete. Tunnels are subjected to various forces and stresses, including ground movement, vibrations, and water pressure. By reinforcing the concrete with stainless steel fibers, the tunnel linings become more resistant to cracking and spalling, which can compromise the structure's integrity. Moreover, the stainless steel fibers have a high resistance to corrosion, making them ideal for tunnel applications. Tunnels are often exposed to harsh environments, such as high humidity, chemical exposure, and saltwater intrusion. These conditions can cause the reinforcement within the concrete to corrode, leading to degradation and reduced durability. However, the corrosion-resistant properties of stainless steel fibers help prevent this deterioration, ensuring the tunnel linings remain structurally sound for an extended period. Additionally, melt extract stainless steel fibers improve the durability of tunnel linings by reducing the risk of fire damage. Tunnels can be vulnerable to fire incidents, which can significantly weaken the concrete and compromise the safety of the structure. The stainless steel fibers act as a reinforcement that can withstand high temperatures, preventing the concrete from rapidly losing its strength during a fire. This increased fire resistance enhances the overall durability and safety of the tunnel linings. In summary, melt extract stainless steel fiber enhances the durability of tunnel linings by improving tensile strength, corrosion resistance, and fire resistance. By reinforcing the concrete and protecting it from cracking, corrosion, and fire damage, these stainless steel fibers ensure that tunnel linings can withstand the various challenges they may encounter, ultimately extending their lifespan and enhancing the overall safety of the tunnels.

- Q: How does melt extract stainless steel fiber affect the ductility of shotcrete?

- The ductility of shotcrete is significantly influenced by the inclusion of melt extract stainless steel fiber. Ductility refers to a material's capability to undergo deformation without fracturing or breaking. When melt extract stainless steel fibers are introduced into shotcrete, they enhance the overall ductility of the substance. The addition of stainless steel fibers boosts the tensile strength of shotcrete, rendering it more resistant to cracking when subjected to tensile stress. These fibers act as reinforcement within the shotcrete matrix, offering additional support and improving the substance's ability to withstand external forces. With the inclusion of melt extract stainless steel fibers, shotcrete experiences increased ductility, allowing it to better accommodate any structural movement or settlement. This is especially crucial in situations where shotcrete is exposed to dynamic loading or ground movements, such as in tunnels or underground structures. Moreover, the improved ductility of shotcrete resulting from the integration of stainless steel fibers also enhances its durability. The fibers aid in the distribution and dissipation of applied loads or stresses more evenly throughout the substance, preventing localized cracking or failure. In summary, the integration of melt extract stainless steel fiber into shotcrete has a positive impact on its ductility by enhancing its tensile strength, increasing its resistance to cracking, and improving its ability to withstand external forces. This makes shotcrete more reliable and suitable for various construction applications, providing enhanced structural performance and longevity.

- Q: How does melt extract stainless steel fiber improve the impact resistance of shotcrete?

- Melt extract stainless steel fiber improves the impact resistance of shotcrete by reinforcing the material and providing additional strength and durability. The fibers are evenly distributed throughout the shotcrete mix, creating a three-dimensional network that enhances its ability to absorb and distribute energy upon impact. This reinforcement prevents cracks and fractures from forming, increasing the overall impact resistance of the shotcrete.

- Q: How does melt extract stainless steel fiber affect the shrinkage of concrete?

- The shrinkage of concrete can be significantly impacted by melt extract stainless steel fiber. When incorporated into concrete mixtures, these fibers aid in minimizing the overall shrinkage of the material. This is attributed to the distinct properties of stainless steel fibers, such as their remarkable tensile strength and minimal thermal expansion coefficient. During the process of curing, concrete undergoes a chemical reaction known as hydration, in which water reacts with cement to form a solid matrix. As this reaction occurs, the water evaporates, resulting in the shrinkage of the concrete. This shrinkage can potentially cause cracks and reduce the durability of the concrete structure. Nevertheless, the inclusion of melt extract stainless steel fibers assists in alleviating this issue by providing reinforcement within the concrete matrix. These fibers function as reinforcement bars, evenly dispersing the stresses generated by shrinkage throughout the concrete. Consequently, the overall shrinkage and subsequent cracking are diminished. Additionally, the low thermal expansion coefficient of stainless steel fibers aids in minimizing the impact of temperature fluctuations on the concrete. Variations in temperature can cause concrete to expand and contract, leading to further shrinkage and potential cracking. The stainless steel fibers help to limit these movements, thereby preserving the integrity of the concrete structure. To summarize, melt extract stainless steel fibers have a positive influence on concrete shrinkage by reducing overall shrinkage and mitigating the possibility of cracking. Their superior tensile strength and minimal thermal expansion coefficient make them an effective reinforcement material, enhancing the longevity and durability of concrete structures.

- Q: What are the main applications of melt extract stainless steel fiber?

- Melt extract stainless steel fiber has several main applications across various industries. Firstly, it is commonly used in the construction industry for reinforcing concrete. The addition of stainless steel fibers to concrete can increase its tensile strength, impact resistance, and durability. This makes it ideal for applications such as industrial flooring, tunnels, bridges, and precast elements. Secondly, melt extract stainless steel fiber is used in the refractory industry. It is added to refractory materials, such as castables and gunning mixes, to enhance their mechanical properties and resistance to thermal shock. The stainless steel fibers help to reinforce these materials, preventing cracking and improving their overall performance in high-temperature environments. Furthermore, the automotive industry utilizes melt extract stainless steel fiber in the manufacturing of brake pads and linings. The fibers are added to the brake friction materials to enhance their strength, stability, and heat dissipation capabilities. This results in improved braking performance and increased durability of the brake components. Additionally, melt extract stainless steel fiber finds application in the textile industry. It is used in the production of high-performance fabrics and garments that require enhanced strength, durability, and resistance to abrasion. Stainless steel fibers are incorporated into the fabric to provide these properties, making them suitable for applications such as protective clothing, military gear, and industrial textiles. Moreover, melt extract stainless steel fiber is utilized in the electrical and electronics industry. It is incorporated into various electronic components, such as printed circuit boards, to enhance their thermal conductivity and mechanical stability. The stainless steel fibers provide efficient heat dissipation and improve the overall performance and reliability of these electronic devices. In summary, melt extract stainless steel fiber has a wide range of applications, including concrete reinforcement, refractory materials, automotive brake components, textiles, and electronic devices. Its unique properties contribute to improved strength, durability, thermal conductivity, and mechanical stability in these various industries.

- Q: Does melt extract stainless steel fiber improve the fire resistance of concrete?

- Indeed, the fire resistance of concrete is enhanced by melt extract stainless steel fiber. By incorporating stainless steel fibers into the concrete, the material gains reinforcement and an enhanced level of strength and durability. In the event of a fire, these fibers play a crucial role in impeding the transmission of heat, thus safeguarding the concrete from cracking or spalling. Moreover, the remarkable melting point of stainless steel guarantees that it retains its structural integrity even in the face of extreme temperatures. Consequently, the fire resistance of the concrete is significantly improved, rendering it a dependable and secure construction material suitable for areas prone to fires.

Send your message to us

Melt Extract Stainless Steel Fiber - Glued Hooked-End Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords