Melt Extract Stainless Steel Fiber - Loose Steel Fiber from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-MC

Material: Color Steel

certificated: ISO 9001

Specifications

We manufacture fibers according customer requirement

Steel fiber types includs,

a) Hooked ends steel fiber

b) Wave steel fiber

c) Needle-flat steel fiber

d) Wavy steel fiber

e) Glued steel fiber

f) Micro-steel fiber

g) stainless steel fiber

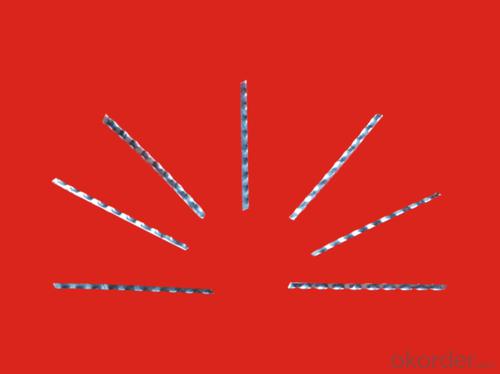

Picture

Steel fiber

Length :30--65 mm

Diameter :0.55--1.0 mm

Tensile strength: >1100 MPA .

Length :25--60 mm

Diameter :0.3--1.2 mm

Tensile strength: >1100 MPA .

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: Can melt extract stainless steel fiber be used in ultra-high-performance concrete (UHPC)?

- Yes, melt extract stainless steel fiber can be used in ultra-high-performance concrete (UHPC).

- Q: Can melt extract stainless steel fiber be used in high-strength shotcrete applications?

- Yes, melt extract stainless steel fiber can be used in high-strength shotcrete applications. This type of fiber provides enhanced strength and durability to the shotcrete, making it suitable for demanding applications that require high-strength materials.

- Q: Does melt extract stainless steel fiber improve the resistance to sulfate attack of concrete?

- Yes, melt extract stainless steel fiber can improve the resistance to sulfate attack of concrete. Sulfate attack is a chemical reaction between sulfate ions and the materials present in the concrete, which can lead to deterioration and decreased durability. By adding stainless steel fibers, the concrete becomes more resistant to sulfate attack due to the corrosion-resistant properties of stainless steel. The fibers act as a reinforcement, enhancing the overall strength and durability of the concrete and reducing the potential for sulfate attack. Additionally, the stainless steel fibers can help prevent cracks from forming, which further reduces the likelihood of sulfate ions penetrating the concrete and causing damage. Overall, the addition of melt extract stainless steel fibers can significantly improve the resistance to sulfate attack in concrete structures.

- Q: What is the effect of melt extract stainless steel fiber on the crack resistance of concrete?

- The effect of melt extract stainless steel fiber on the crack resistance of concrete is that it significantly improves the overall crack resistance. The addition of these fibers helps to distribute the stress throughout the concrete, reducing the formation and propagation of cracks. This leads to increased durability and longevity of the concrete structure.

- Q: What is the effect of melt extract stainless steel fiber on the flexural toughness of concrete?

- The addition of melt extract stainless steel fiber to concrete has a positive effect on the flexural toughness of the material. The fibers act as reinforcement, increasing the overall strength and resistance to cracking or failure under bending or flexural forces. This leads to improved durability and increased load-bearing capacity of the concrete, making it more suitable for applications where flexural strength is crucial.

- Q: What is the effect of melt extract stainless steel fiber on the modulus of plasticity of concrete?

- Adding melt extract stainless steel fibers to concrete enhances its modulus of plasticity, boosting overall flexural strength and ductility. These fibers strengthen the concrete and enable it to withstand bending forces without fracturing. The presence of these fibers in the concrete matrix evenly distributes the load, preventing crack formation and propagation. This improves the modulus of plasticity, which refers to the material's ability to deform under stress without permanent deformation or failure. By increasing the modulus of plasticity, melt extract stainless steel fibers contribute to a more durable and resilient concrete structure. Moreover, these fibers improve the post-cracking behavior of concrete. Even after the concrete cracks under load, the stainless steel fibers hold the cracked sections together, limiting further crack propagation. This enhances the concrete's performance by increasing its resistance to fatigue and reducing the potential for sudden failure. In conclusion, incorporating melt extract stainless steel fibers in concrete positively impacts the modulus of plasticity by enhancing flexural strength, ductility, and crack resistance. This results in a more resilient and durable concrete structure that can handle higher loads, reducing maintenance needs and extending the lifespan of the construction project.

- Q: Can melt extract stainless steel fiber be used in parking lot pavements?

- Indeed, melt extract stainless steel fiber is applicable for utilization in parking lot pavements. It is a prevalent practice to employ stainless steel fibers as reinforcement in concrete, thereby enhancing its robustness, endurance, and resistance to fractures. Considering the substantial loads and frequent traffic endured by parking lot pavements, the inclusion of stainless steel fibers can significantly augment the pavement's overall performance and lifespan. These fibers function as reinforcements, effectively dispersing stresses and impeding the creation and spread of cracks. Consequently, this can minimize the necessity for maintenance and elongate the pavement's existence, rendering it a judicious and cost-efficient selection for parking lot construction.

- Q: Can melt extract stainless steel fiber be used in architectural concrete applications?

- Certainly, architectural concrete applications can utilize melt extract stainless steel fiber. These fibers, extracted by melting, possess remarkable tensile strength and corrosion resistance, making them highly effective in reinforcing architectural concrete. Not only do they enhance the structural integrity of the concrete and provide added safeguard against environmental factors and heavy loads, but they also contribute to its strength, durability, and crack resistance. Furthermore, the inclusion of stainless steel fibers can greatly improve the final product's aesthetic appeal, as they can be effortlessly polished to achieve a sleek and lustrous surface. In summary, melt extract stainless steel fibers are an ideal choice for architectural concrete applications, offering both functional and visual advantages.

- Q: Can melt extract stainless steel fiber be used in tunnel lining applications?

- Melt extract stainless steel fiber is suitable for tunnel lining applications. It possesses high tensile strength, corrosion resistance, and durability, making it an ideal material for reinforcing tunnel linings. By enhancing the structural integrity and stability of the tunnel, it effectively prevents cracking, spalling, and other types of damage. Moreover, stainless steel fibers offer excellent fire resistance properties, which are crucial in tunnel environments. In summary, melt extract stainless steel fiber is a robust and resilient option for tunnel lining applications, capable of withstanding the challenging conditions commonly encountered in tunnels.

- Q: Can melt extract stainless steel fiber be used in shotcrete applications?

- Indeed, shotcrete applications can incorporate melt extract stainless steel fiber. Shotcrete entails the application of concrete or mortar via a high-pressure hose, and the inclusion of stainless steel fibers can augment the shotcrete's effectiveness and durability. Typically, melt extract stainless steel fibers are introduced into the shotcrete mixture to enhance its resistance to cracking, diminish shrinkage, and bolster its tensile and flexural strength. Moreover, these fibers aid in regulating crack formation and impede their propagation, resulting in a shotcrete structure that is more enduring and long-lasting. Consequently, the integration of melt extract stainless steel fiber in shotcrete applications can substantially heighten the overall performance and longevity of the shotcrete.

Send your message to us

Melt Extract Stainless Steel Fiber - Loose Steel Fiber from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords