Manufacturer Stainless Steel 304 321 316 plate for industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Manufacturer stainless steel 304 321 316 plate for industry

Product Description

We have bulit strategetic partnership with TISCO, POSCO, BAOSTEEL, JISCO LISCO several years. Customers shouldn't have concern with our products, product could endure time.

Type: 201, 202, 304, 304L, 309S, 310S, 310H , 314 ,316, 316L, 316Ti, 317, 317L, 347, 347H , 321, 403 , 405 ,409, 409L, 410 , 410L , 420, 429 , 430, 434 ,444, 904L , 2014 and 2205 ,Uranus 65 ,C126

Martensite-Ferritic: Ss 405 , 409, 409L, 410, 420, 420J1 , 420J2 , 420F , 430 ,431 sheet / plate;

Austenite Cr-Ni -Mn: Ss 201 sheet, ss 202 sheet, J4 ss coil;

Austenite Cr-Ni: SS 304 sheet, SS 304L sheet, ss 309S sheet, ss 310S plate;

Austenite Cr-Ni -Mo: Stainless steel 316 plate, stainless steel 316L plate;

Super Austenitic: 904L Stainless steel sheet , 2205 stainless steel sheet ,253MA stainless steel plate 254SMO stainless steel plate , 654MO stainless steel Plate,

Duplex : S32304 , S32550 ,S31803 ,S32750

EN Standard:

Austenitic: 1.4372 ,1.4373, 1.4310, 1.4305, 1.4301, 1.4306 , 1.4318 ,1.4335, 1.4833 , 1.4835 , 1.4845, 1.4841, 1.4401 , 1.4404 , 1.4571 ,1.4438, 1.4541 , 1.4878 , 1.4550 , 1.4539 , 1.4563 , 1.4547

Duplex: 1.4462 , 1.4362 ,1.4410 , 1.4507

Ferritic :1.4512, 1.400 , 1.4016 ,1.4113 , 1.4526 ,1.4521 , 1.4530 , 1.4749 ,1.4057;

Martensitic: 1.4006 , 1.4021 ,1.4418 ,S165M ,S135M;

GB Standard :

Martensitic: 1Cr12 , 1Cr13Mo , 0Cr13 ,1CR13 ,2Cr13 , 3Cr13 , 4C13 , 7Cr17 , 8Cr17 ,11Cr17 , 9Cr18Mo ;

Ferritic: 00Cr12 ,1CR17 ,0Cr13AL , 1Cr17Mo , 1Cr15 , 1Cr25Ti , 00Cr17 , 00Cr18Mo2 00Cr27Mo ;

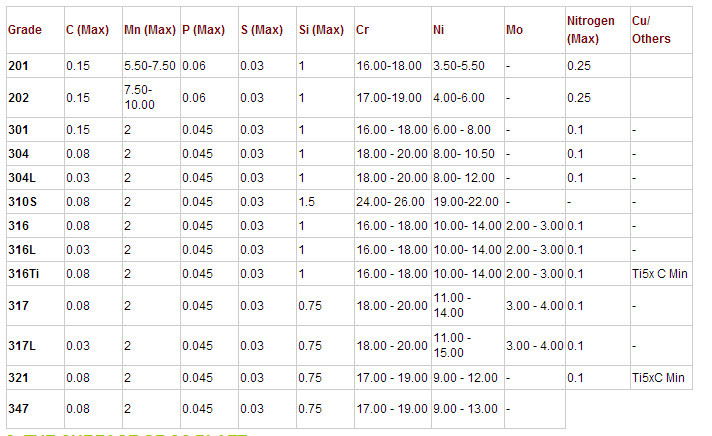

Chemical Composition

Packaging & Shipping

1.Packaging:All products are packaged according to the Standard export packing.In order to prevent friction damage and water erosion and so on.

2.Shipping: Ocean transportation,land transportation or air transportation.

- Q: What is the minimum order quantity for stainless steel sheets?

- The minimum order quantity for stainless steel sheets can vary depending on the supplier and the specific type and size of the sheets. It is recommended to contact the supplier directly to inquire about their minimum order quantity.

- Q: Can stainless steel sheets be bent?

- Yes, stainless steel sheets can be bent. However, the degree of bendability depends on the thickness and grade of the stainless steel.

- Q: Can stainless steel sheets be used for automotive applications?

- Certainly, automotive applications can make use of stainless steel sheets. Renowned for its versatility and durability, stainless steel proves to be an exceptional material that exhibits remarkable resistance against corrosion, heat, and impact. These exceptional qualities render it highly suitable for automotive applications wherein durability and resistance against harsh environments are crucial aspects. Stainless steel sheets find utility across various domains of the automotive industry, encompassing body panels, exhaust systems, fuel tanks, and even interior components. Moreover, stainless steel can be effortlessly shaped, welded, and manipulated to meet precise design prerequisites, thus solidifying its status as a favored option within the automotive industry.

- Q: What is the bending strength of stainless steel sheets?

- The bending strength of stainless steel sheets can vary depending on the specific grade and thickness of the sheet. However, stainless steel is generally known for its high strength and rigidity, making it suitable for various applications that require strong and durable materials.

- Q: How to clean stainless steel plate cleaning?

- Grease can be applied to soft cloth to dissolve alcohol. I was impressed with how the grease turned off my pizza oven. Some thicker deposits did not respond once to a cloth, but I had been rubbing them with alcohol and completely disappeared within one or two minutes. With other methods, it is important to rinse off the alcohol and dry it so that it has a shiny metal.

- Q: What is the magnetic permeability of stainless steel sheets?

- The magnetic permeability of stainless steel sheets can vary depending on the specific alloy and processing conditions. Generally, stainless steel is considered to have a low magnetic permeability, making it a poor conductor of magnetic fields. However, some types of stainless steel, such as ferritic stainless steel, have a higher magnetic permeability compared to other grades like austenitic stainless steel. It is important to note that the magnetic permeability of stainless steel can also be affected by factors such as temperature and the presence of external magnetic fields. Therefore, it is best to consult specific technical data or perform magnetic permeability testing for accurate and detailed information about the magnetic properties of stainless steel sheets.

- Q: Are stainless steel sheets suitable for architectural mesh or screens?

- Yes, stainless steel sheets are highly suitable for architectural mesh or screens. They possess excellent durability, corrosion resistance, and aesthetic appeal, making them ideal for various architectural applications. Additionally, stainless steel sheets offer flexibility in design, allowing for intricate patterns and shapes in architectural mesh or screens.

- Q: What are the features of stainless steel plates?

- According to the method of hot and cold rolled two categories, including thickness 0.5.10-885 mm 72938 thin cold plate and 4.5-100 mm thick plate.

- Q: What is the thickness range for stainless steel sheets?

- The thickness of stainless steel sheets can differ based on the grade and application at hand. In general, stainless steel sheets come in thicknesses that span from 0.4mm to 6mm. Nonetheless, specific purposes may necessitate the use of thinner or thicker sheets. To ascertain the suitable thickness range for a particular project or application, it is crucial to seek advice from a supplier or consult industry standards.

- Q: How do I prevent stress relaxation on stainless steel sheets?

- Stress relaxation is a phenomenon that occurs in stainless steel sheets when they are subjected to prolonged exposure to high temperatures or constant stress. To prevent stress relaxation on stainless steel sheets, you can take the following measures: 1. Proper selection of stainless steel grade: Different grades of stainless steel have varying resistance to stress relaxation. Choose a grade that offers high resistance to this phenomenon, such as austenitic stainless steels like Type 304 or Type 316. 2. Avoid excessive temperatures: Stainless steel sheets should be operated within their recommended temperature limits. Exposing them to temperatures beyond their specified range can accelerate stress relaxation. Ensure that the operating temperature remains within the permissible limits. 3. Control the stress levels: Minimize the stress levels applied to the stainless steel sheets during fabrication and installation. Avoid excessive bending, stretching, or deformation that could introduce stress into the material. Properly design and fabricate the components to reduce stress concentration points. 4. Post-weld heat treatment: If the stainless steel sheets are welded, consider performing a post-weld heat treatment. This process involves subjecting the welded area to controlled heating and cooling cycles to relieve residual stresses and minimize the potential for stress relaxation. 5. Reduce exposure to aggressive environments: Stainless steel sheets are corrosion-resistant, but exposure to aggressive chemicals or environments can accelerate stress relaxation. Avoid prolonged exposure to corrosive substances or environments that may compromise the material's integrity and cause stress relaxation. 6. Regular inspections and maintenance: Periodically inspect the stainless steel sheets for signs of stress relaxation, such as deformation, cracks, or changes in dimensions. Regular maintenance and timely repairs can help identify and address any issues before they worsen. 7. Consult with experts: If you are unsure about the specific requirements to prevent stress relaxation in your stainless steel sheets, consult with metallurgical experts or stainless steel manufacturers. They can provide guidance on the best practices and materials to ensure long-term performance and prevent stress relaxation. By implementing these preventive measures, you can significantly reduce the risk of stress relaxation in stainless steel sheets, ensuring their durability and maintaining their structural integrity over time.

Send your message to us

Manufacturer Stainless Steel 304 321 316 plate for industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords