Manufacture Forged Steel Round Bar S45C(1045)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Type:

Carbon Steel,Spring Steel,Bearing Steel,Gear Steel,Deformed Steel,Stainless Steel,Alloy Steel

Shape:

Steel Coil,Steel Sheet,Steel Wire Rod,Steel Flat Bar,Steel Square Bar,Steel Angle,Steel Round Bar,Steel Billets

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

50mmm-800mm

Width:

50mmm-800mm

Length:

6-12m

Outer Diameter:

50mmm-800mm

Net Weight:

100kg

Packaging:

seaworthy packaging

Manufacture Forged Steel Round Bar S45C

Detailed Information of Manufacture Forged Steel Round Bar S45C

| Name | Steel Round Bar |

| Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

| Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

| Surface Treatment: | Black/Peeling/Polished/Machined |

| Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

| Test | SGS/UT 100% Elements Testing |

| Certificate: | ISO/Mill Certificate |

| Service: | 24 hours online service / |

| more than 20 years trading and manufacture | |

| Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

| Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Product Overviews of Manufacture Forged Steel Round Bar S45C

| Product Name | Typical Grades | Diameter(mm) | Standard Adopted |

| Carbon Steel | 20 (1020/S20C/C22) | ||

| 40 (1040/S40C/C40) | Ø16-Ø300 | ||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | ||

| GCr15 (52100/SUJ2/100Gr6) | Ø12-Ø250 | ||

| GCr9SiMn (A485-Gr.1/SUJ3) | GB/SAE/ | ||

| Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | JIS/DIN | |

| 40Cr (5140/SCr440/41Cr4) | Ø12-Ø250 | ||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | ||

| 20CrMn(5115/SMnC420/20MnCr5) | Ø16-Ø600 | ||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Company Introduction of Manufacture Forged Steel Round Bar S45C

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

| After-sale service | l CNBM provides the services and support you need for every step of our cooperation. We’re the business partners you can trust; you can relax and get on with doing business. |

| l For any problem, please kindly contact us at any your convenient time, we’ll reply you in our first priority within 24 hours | |

| Advantages | l Industry experience over 20 years. |

| l Shipment of goods -More than 70 countries worldwide. | |

| l The most convenient transport and prompt delivery. | |

| l Competitive price with best service. | |

| l High technical production line with top quality products. | |

| l High reputation based on best quality products. | |

Packaging & Delivery of Manufacture Forged Steel Round Bar S45C

| Packaging Detail | Sea worthy packing /as per customer's packing instruction |

| Delivery Detail | 15 ~ 40 days after receiving the deposit |

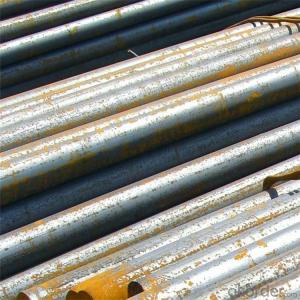

Products Show

FAQ:

| Are you a trading company or manufacturer? | Manufacturer |

| What’s the MOQ? | 1000m2 |

| What’s your delivery time? | 15-20 days after downpayment received |

| Do you Accept OEM service? | Yes |

| what’s your delivery terms? | FOB/CFR/CIF |

| What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

| Western Union acceptable for small amount. | |

| L/C acceptable for large amount. | |

| Scrow ,Paybal,Alipay are also ok | |

| Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

| What's your available port of Shipment? | Main Port, China |

| What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

| Where are your Market? | Covering more than 160 countries in the world |

- Q: Can special steel be used in the telecommunications industry?

- Yes, special steel can be used in the telecommunications industry. It is often used in the construction of telecommunication towers, antennas, and transmission lines due to its high strength, corrosion resistance, and durability.

- Q: How does special steel enhance the performance of cutting tools?

- Special steel brings about various enhancements to the performance of cutting tools. To begin with, special steel is specifically designed to possess greater hardness and wear resistance in comparison to standard steel. This heightened hardness ensures that cutting tools retain their sharpness for extended periods, resulting in improved cutting efficiency and accuracy. Furthermore, the exceptional wear resistance of special steel guarantees that the cutting edges of the tools do not wear down quickly, allowing them to endure the substantial forces and pressures involved in cutting operations. Moreover, special steel often exhibits superior toughness and strength when compared to regular steel. This augmented toughness enables cutting tools to endure impacts and vibrations without succumbing to breakage or chipping, thus ensuring their durability and longevity. Additionally, the increased strength of special steel empowers cutting tools to handle higher cutting speeds and feed rates, ultimately enhancing productivity and reducing machining time. Special steel also boasts excellent heat resistance properties, which are crucial for cutting tools subjected to elevated temperatures during machining processes. This heat resistance prevents the cutting edges from softening or deforming, circumstances that could lead to subpar cutting performance and reduced tool lifespan. Additionally, special steels can possess improved corrosion resistance, effectively shielding the tools from rust or corrosion caused by exposure to moisture or aggressive cutting fluids. In conclusion, the distinctive properties of special steel, including heightened hardness, wear resistance, toughness, strength, heat resistance, and corrosion resistance, all work together to enhance the performance of cutting tools. These characteristics enable cutting tools to maintain their sharpness, withstand high forces and temperatures, resist wear and corrosion, and ultimately improve cutting efficiency, accuracy, and tool lifespan.

- Q: What are the applications of special steel in the manufacturing sector?

- Special steel has numerous applications in the manufacturing sector due to its exceptional properties. It is commonly used in industries such as automotive, aerospace, construction, and machinery manufacturing. Special steel is utilized for manufacturing high-performance components, tools, and machinery parts that require superior strength, durability, and resistance to wear and corrosion. Its applications range from manufacturing gears, shafts, bearings, and springs to constructing bridges, buildings, and pipelines. Additionally, special steel finds use in the production of cutting tools, molds, and dies, further enhancing the efficiency and precision of manufacturing processes.

- Q: What are the benefits of using special steel in the energy sector?

- There are several benefits of using special steel in the energy sector. Firstly, special steel offers exceptional strength and durability, making it an ideal material for constructing various energy infrastructure components such as pipelines, pressure vessels, and turbines. Its high tensile strength and resistance to corrosion ensure that these structures can withstand the harsh conditions and pressures encountered in the energy sector, reducing the risk of failures and increasing their lifespan. Secondly, special steel exhibits excellent heat resistance properties, which is crucial in the energy sector where high temperatures are generated. This makes it suitable for applications such as power generation, where it can be used in the construction of boilers, heat exchangers, and nuclear reactors. The ability of special steel to withstand extreme heat without deforming or losing its mechanical properties is vital for ensuring the safe and efficient operation of energy facilities. Moreover, special steel offers superior weldability and formability, allowing for easier fabrication and assembly of complex energy infrastructure components. This makes it easier and more cost-effective to manufacture and install equipment in the energy sector, reducing both production costs and construction time. Another advantage of using special steel in the energy sector is its resistance to fatigue and cracking. Energy infrastructure components are subjected to cyclic loading and stress, which can lead to fatigue failure over time. Special steel's ability to resist fatigue and crack propagation ensures the long-term reliability and safety of energy infrastructure. Furthermore, special steel offers excellent magnetic properties, making it suitable for use in power transmission and electrical equipment. Its magnetic permeability and low electrical resistance allow for efficient transmission and distribution of electricity, reducing energy losses and improving overall system performance. Overall, the benefits of using special steel in the energy sector include enhanced strength, durability, heat resistance, weldability, and fatigue resistance. These properties contribute to the reliability, safety, and efficiency of energy infrastructure, making special steel an invaluable material for the energy sector.

- Q: What are the different methods of improving the fatigue resistance of special steel?

- There are several methods that can be employed to improve the fatigue resistance of special steel. These methods aim to enhance the material's ability to withstand cyclic loading and prevent fatigue failure. 1. Heat Treatment: One common method is to subject the special steel to heat treatment processes such as annealing, normalizing, or quenching and tempering. These treatments can alter the microstructure of the steel, improving its strength, toughness, and fatigue resistance. 2. Surface Treatment: Applying surface treatments like shot peening or surface hardening can significantly enhance the fatigue resistance of special steel. Shot peening involves bombarding the surface with small, high-velocity steel shots, inducing compressive stresses that counteract the tensile stresses during cyclic loading. Surface hardening techniques, such as carburizing or nitriding, create a hardened layer on the surface of the steel, which increases its resistance to fatigue. 3. Alloying: Modifying the composition of the special steel by adding specific alloying elements can greatly enhance its fatigue resistance. For example, adding elements like chromium, molybdenum, or nickel can improve the material's strength, ductility, and resistance to fatigue crack initiation and propagation. 4. Grain Refinement: Refining the grain structure of the special steel can lead to improved fatigue resistance. Techniques like severe plastic deformation or grain refinement through thermomechanical processing can promote the formation of finer grains, which reduce the susceptibility to fatigue crack initiation and propagation. 5. Microstructural Control: Optimizing the microstructure of the special steel can be achieved through techniques such as controlled rolling, controlled cooling, or precipitation hardening. These methods aim to achieve a desirable microstructural balance, such as fine dispersion of precipitates or a refined grain structure, which improves the material's fatigue resistance. 6. Residual Stress Control: Managing residual stresses within the special steel can help improve its fatigue resistance. Techniques like stress relieving or balancing residual stresses through appropriate heat treatment can reduce the likelihood of fatigue crack initiation and propagation. It is important to note that the specific method or combination of methods employed to enhance fatigue resistance will depend on the specific alloy and application requirements. Additionally, thorough testing and evaluation should be conducted to ensure the effectiveness of these methods in improving the fatigue resistance of special steel.

- Q: How does special steel perform at high temperatures?

- Special steel is designed to maintain its strength and resistance to deformation even at high temperatures. It exhibits excellent heat resistance, high thermal conductivity, and retains its mechanical properties, making it ideal for applications that require stability and durability in extreme heat environments.

- Q: What is the process of manufacturing special steel?

- The process of manufacturing special steel involves several steps to ensure the production of high-quality and durable steel with specific properties. 1. Raw Materials Selection: The first step is to carefully select the raw materials required for making special steel. This includes iron ore, coal, and other alloying materials such as chromium, nickel, and manganese, depending on the desired properties of the final product. 2. Melting: The selected raw materials are then melted in a large furnace, often through the use of electric arc furnaces or basic oxygen furnaces. These furnaces heat the raw materials to extremely high temperatures, typically around 1,600 to 2,000 degrees Celsius, to transform them into molten metal. 3. Refining: Once the raw materials are melted, the molten metal undergoes a refining process to remove impurities. This is done through techniques like degassing, desulphurization, and deoxidation, ensuring that the steel is free from unwanted elements that may negatively impact its properties. 4. Alloying: After refining, alloying elements are added to the molten metal to achieve the desired properties. These elements can modify the steel's strength, hardness, corrosion resistance, and other characteristics. The specific alloying elements and their proportions depend on the intended application of the special steel. 5. Continuous Casting: The molten steel is then poured into a continuous casting machine, which solidifies it into semi-finished products called billets, blooms, or slabs. This continuous casting process ensures a consistent and uniform structure throughout the steel. 6. Hot Rolling: The semi-finished products are then reheated and passed through a series of hot rolling mills. This process involves reducing the thickness and shaping the steel into various forms such as bars, rods, plates, or sheets, depending on the intended use. 7. Heat Treatment: After hot rolling, the steel may undergo heat treatment processes such as annealing, quenching, tempering, or case hardening. These treatments help to further enhance the mechanical properties of the steel, such as its hardness, toughness, and ductility. 8. Finishing: The final step involves surface finishing and quality control measures. The steel is inspected for any defects or imperfections that may have occurred during the manufacturing process. Surface treatments like pickling or galvanizing can also be applied to enhance the steel's appearance and protect it from corrosion. Overall, the process of manufacturing special steel is a complex and precise operation that requires careful selection of raw materials, melting, refining, alloying, continuous casting, hot rolling, heat treatment, and finishing. This ensures that the resulting steel meets the specific requirements and performance characteristics demanded by various industries.

- Q: What are the different surface finishing techniques for special steel?

- Some of the different surface finishing techniques for special steel include electroplating, powder coating, passivation, etching, and polishing.

- Q: How is die steel used in metal stamping processes?

- Die steel is used in metal stamping processes as it is a strong and durable material that can withstand the high pressures and forces involved in shaping and forming metal. It is used to create dies, which are specialized tools that are used to shape and cut metal into specific designs or forms. The die steel acts as a mold or template, allowing the metal to be stamped, bent, or cut into the desired shape with precision and accuracy.

- Q: How does special steel perform in terms of magnetic properties?

- Special steel typically has low magnetic permeability, meaning it has poor magnetic properties. This is due to the presence of alloying elements such as chromium and nickel, which help in reducing the material's magnetic susceptibility. However, there are certain types of special steels, such as ferritic stainless steels, that have higher magnetic permeability. Overall, the magnetic properties of special steel can vary depending on its composition and intended application.

Send your message to us

Manufacture Forged Steel Round Bar S45C(1045)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords