High Quality Aluminum Alloy Sheet Manufactory 2024

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Manufactory 2024 Aluminium Alloy Sheet Description:

T6 Alloy Aluminum Plate 7022 adds to the 3%-7.5% of zinc-containing alloys of magnesium, can form the strengthening effect of MgZn2, make the alloy heat treatment effect than on the aluminum-zinc alloy. Improve the content of zinc and magnesium alloys, the tensile strength will be further improved, but its resistance to stress corrosion and spalling corrosion will decline. Subjected to heat treatment and can reach very high strength characteristics. 7022 material is generally a small amount of copper, chrome, alloy, the 7022 aluminum alloy is the top grade, known as the most excellent products in aluminum alloy, high strength, far better than any mild steel.

2.Main Features of Manufactory 2024 Aluminium Alloy Sheet:

PVC Protect Film

Waterproof paper

High Quality

Competitive Price

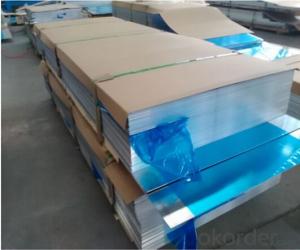

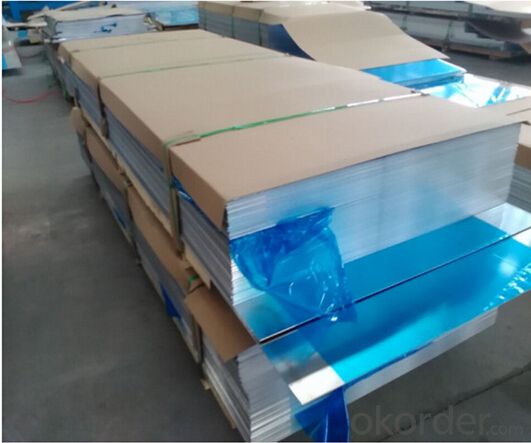

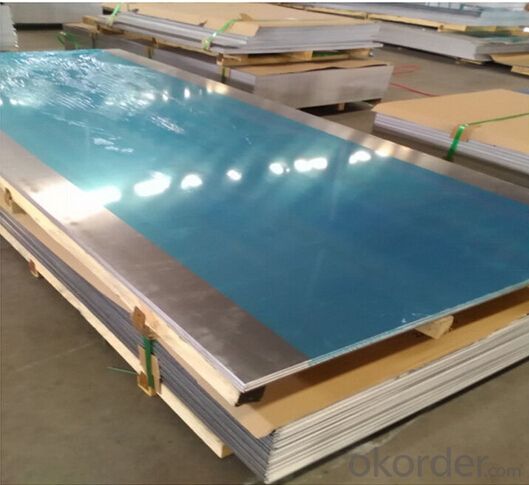

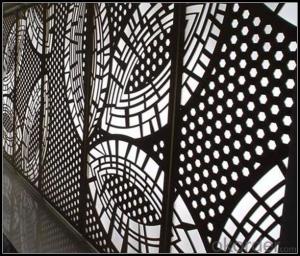

3. Manufactory 2024 Aluminium Alloy Sheet Images:

4. Manufactory 2024 Aluminium Alloy Sheet Specification:

Commodity | manufactory 2024 Aluminium alloy Sheet |

Material |

1050,1060,1100,2024,2204,2A16(LY16),2A06(LY6),3003,3004,5052, 5005,5083,6061,6063 |

Finish (Surface) |

Hairline Finish,Mirror Finish,Oxidation Finish,PS Finish,Embossed Finish |

Thickness |

0.15mm~200mm |

Width |

10mm~2500mm |

Length |

2000mm~2500mm |

Application |

Aluminium Sheet can apply to Lighting,solar reflective film,building

appearance,interior decorating:Ceilings,walls, furniture,cabinets,elevators, signs,

nameplates,bags,automotive interior and exterior decoration Upholstery:Photo

Frame;household appliances:refrigerators,microwave ovens,audio equipment,etc.

aerospace and military aspects, such as China's large aircraft manufacturing,the

Shenzhou spacecraft series,satellite.the mechanical parts processing,mold

making,chemical/thermal insulation pipes coated. |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Is it possible to utilize aluminum in the construction of automobiles?

- <p>Yes, aluminum is widely used in automobiles due to its lightweight, high strength, and excellent corrosion resistance. It is commonly found in engine components, body panels, and wheels. The use of aluminum can lead to reduced vehicle weight, which improves fuel efficiency and reduces emissions. Additionally, aluminum's recyclability makes it an environmentally friendly choice for automotive manufacturing.</p>

- Q: This question asks for the benefits or positive attributes that aluminum has compared to other types of metals.

- <p>Aluminum offers several advantages over other metals, including its low density, which makes it lightweight and ideal for applications requiring reduced weight. It also has excellent corrosion resistance, protecting it from rust and other forms of degradation. Aluminum is highly malleable and ductile, allowing it to be easily shaped into various forms. It has high thermal and electrical conductivity, making it suitable for heat exchangers and electrical wiring. Additionally, aluminum is abundant and relatively inexpensive compared to other metals, and it is fully recyclable with minimal loss in quality, contributing to its sustainability.</p>

- Q: Explain the impact of high-temperature cooking on aluminum cookware.

- <p>High-temperature cooking can have detrimental effects on aluminum cookware. When exposed to high heat, aluminum can react with acidic or alkaline foods, potentially causing the release of aluminum particles into the food. This can lead to a change in the taste and color of the food, and over time, it may also lead to the degradation of the cookware's surface, causing it to become discolored or pitted. Additionally, there are health concerns related to the ingestion of aluminum, although these are still a subject of debate among scientists. It's generally recommended to use aluminum cookware on low to medium heat to preserve both the quality of the food and the longevity of the cookware.</p>

- Q: Explain the natural relationship between aluminum and magnesium, focusing on their abundance and reactivity in the Earth's crust.

- <p>Aluminum and magnesium are both abundant elements in the Earth's crust, with aluminum being the most abundant metal and magnesium being the eighth most abundant element overall. They are often found in close association within the same minerals, such as in aluminosilicates and some carbonates. Both elements are highly reactive, forming compounds readily with oxygen to create oxides and silicates. However, they differ in their reactivity with water; aluminum forms a protective oxide layer that prevents further reaction, while magnesium reacts more readily with water to form magnesium hydroxide. This difference in reactivity influences their distribution and the types of compounds they form in nature.</p>

- Q: Explain the interaction between aluminum and oxygen.

- <p>Aluminum and oxygen have a reactive relationship. When aluminum is exposed to oxygen, it forms a thin, protective layer of aluminum oxide on its surface. This oxide layer prevents further oxidation of the aluminum beneath it, making aluminum a corrosion-resistant metal. The reaction is exothermic and can be represented by the chemical equation: 4Al + 3O2 鈫?2Al2O3. This aluminum oxide layer is hard and stable, which is why aluminum is widely used in various applications where resistance to corrosion is important.</p>

- Q: Besides other special pots, can other aluminum pots be used?

- Aluminum pots are not working wellChasing the answerAluminum pots are not working wellStainless steel pots available.

- Q: This question asks about the method to determine the strength of aluminum alloy, which is a measure of its ability to withstand stress or deformation before breaking.

- <p>The strength of aluminum alloy is calculated through a series of mechanical tests, primarily the tensile test. In this test, a sample of the alloy is subjected to a gradually increasing tensile force until it fractures. The yield strength is noted at the point where the alloy begins to deform plastically, and the ultimate tensile strength (UTS) is recorded at the point of fracture. The strength is expressed in units of stress (e.g., MPa or psi). Additionally, the hardness of the alloy can be measured using tests like the Brinell or Rockwell hardness test. These values, along with other properties like elongation and reduction of area, provide a comprehensive understanding of the alloy's strength and ductility.</p>

- Q: This question asks for examples of how recycled aluminum can be utilized.

- <p>Recycled aluminum has numerous applications, including the manufacturing of beverage cans, automotive parts, construction materials, and electronic components. It is also used in the production of aluminum foil, packaging materials, and various household items. Recycled aluminum is valued for its durability, lightweight properties, and energy efficiency in production, making it an environmentally friendly choice for many industries.</p>

- Q: This question asks about the impact of using recycled aluminum on the economy and society. It seeks to understand the benefits and consequences of this practice.

- <p>The use of recycled aluminum has significant positive effects on the economy and society. Economically, it reduces the demand for raw materials, lowering costs and conserving natural resources. It also creates jobs in recycling and manufacturing sectors, stimulating economic growth. Environmentally, recycling aluminum saves energy, as it requires only 5% of the energy needed to produce new aluminum from bauxite ore. This reduces greenhouse gas emissions and lessens the environmental impact of mining. Additionally, it helps in waste management by reducing landfill waste, contributing to a cleaner and more sustainable society.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum in the construction of solar panels.

- <p>Aluminum offers several advantages in solar panel construction, such as its lightweight nature, which reduces the overall weight of the panels and makes them easier to install. It is also highly conductive, enhancing the efficiency of electricity generation. Additionally, aluminum is corrosion-resistant and durable, which means it can withstand harsh weather conditions and last longer. However, there are disadvantages, such as its relatively low strength compared to other metals, which could lead to damage under high stress. Aluminum also has a higher reflectivity, which can reduce the amount of sunlight absorbed by the solar cells. Lastly, while aluminum is abundant, its extraction and processing can have environmental impacts, contributing to carbon emissions and resource depletion.</p>

Send your message to us

High Quality Aluminum Alloy Sheet Manufactory 2024

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords