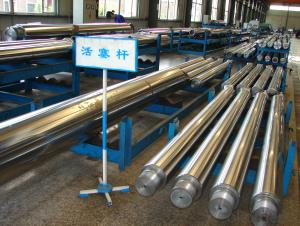

Farm Small Tractor Loader Scoop Excavator Welded Hydraulic Ram

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q: Can the hydraulic cylinder change the nitrogen cylinder?

- This estimate is not, first consider the seal hydraulic oil cylinder and the air cylinder design according to different media, sealing is certainly not the same, if the hydraulic oil cylinder into the cylinder may be sealed and lax circumstance.

- Q: Is it possible to change the hydraulic cylinder of the hydraulic lifting platform to the cylinder?

- As long as you can bore is large enough, the theory on the line! But in fact, considering space and other issues, you can not change it.

- Q: what to use, there is no suitable cylinder, the company's gas supply is not enough, my device does not have much pressure.The pressure of the air pressure is enough, but the air source is insufficient, and the suitable cylinder can not be selected, so the hydraulic station is used to control the cylinder, but there is no such device, and the friend who knows it tells the thanks!

- At the same speed, under the same thrust conditions, the hydraulic system is much more expensive than the pneumatic system. You can use the hydraulic station to control the cylinder. You might as well buy an air compressor alone.If you have a hydraulic station or a large central hydraulic source, you must use the hydraulic system, you can reduce the work pressure, down to 0.8 MPa, and then send the hydraulic oil to the cylinder, you can also work.

- Q: How much is the 1000 ton hydraulic cylinder

- The rated working pressure of general press is 25MpaUsually made of 700mm large diameter (the actual calculated is about 715)

- Q: The cylinder is the same as the cylinder, crane

- 2. the thrust of the cylinder is greater than that of the cylinder. Not only the high oil pressure, but also the diameter of the cylinder to avoid too big design;The 3. cylinder piston moves much faster than the cylinder piston. The gas tank shall be supplied with a large amount of rated pressure in a short time, while the high pressure oil shall be supplied by the high pressure oil pump in the course of operation, with limited flow.

- Q: What is the difference between the cylinder seal and the cylinder seal?

- The medium of bees is different. One is gas sealed, and the other is liquid sealed.

- Q: One hundred1: cylinder 150D-71x-102: cylinder GTD-80/090-P17M3: cylinder XQGA125*160-CA4: hydraulic cylinder COA3110715.035: cylinder MAB125-165P6: hydraulic cylinder SCI80/56 H1765XV980YPSX7: hydraulic cylinder CA100*70*350T8: hydraulic cylinder COA3112458.029: pneumatic gate valve cylinder DN600I need to find each cylinder bore. Stroke. The diameter of the piston rod installation. Pressure rating!!!Urgent need for support for the master! Thank you!!! (the more specific, the more important.)What's the form? Do not understand.. can not point out in detail...

- Where did you get the specifications for each cylinder? Just look for a sample of the brand, and you can see the parameters you need!!! Otherwise, there is no way! Moreover, you can see, you do not write a lot of specifications! So, you still need..... Ha-ha!

- Q: Are hydraulic cylinders, oil cylinders, hydraulic cylinders all the same? What's the difference?

- It's all about one thingI am the repair cylinderThe cylinder is all hydraulic, so it is called a hydraulic cylinder and a hydraulic cylinder, both of which mean one

- Q: Can cylinder be used as cylinder, cylinder and hydraulic cylinder, Yantai hydraulic cylinder?

- The key is to see what kind of system you use and how high the pressure is. In general, the pressure of the hydraulic system is higher, and the pressure is lower.

- Q: What are the components of the cylinder and the hydraulic cylinder?

- Hello, are you asking about the cylinders and cylinders? Cylinder barrel, upper and lower end cover, pull rod, sealing ring and so on. I am a professional, do this, what problems can continue to ask me?

Send your message to us

Farm Small Tractor Loader Scoop Excavator Welded Hydraulic Ram

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords