Ductile Iron Tee

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton pc

- Supply Capability:

- 50,000 Ton Per Year pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A All Socket Tee

K14

Available in T Type and K Type;

Size: DN80-2000

We are involved in the manufacture and supply of the ductile iron All Socket Tee. We manufacture these with the premium quality raw materials. Our All Socket Tee ensure high durability and strength. Our range of All Socket Tees caters to various industrial requirements. We offer these All Socket Tees in different sizes and lengths in order to meet the various requirements of our esteemed clients.

|

Nominal Diameter |

L |

H |

Mass(kg) | ||

|

DN |

dn |

T Type |

K Type | ||

|

80 |

80 |

170 |

85 |

12.5 |

17.7 |

|

100 |

80 |

170 |

95 |

14.8 |

21.5 |

|

100 |

100 |

190 |

95 |

16.1 |

23.5 |

|

150 |

80 |

170 |

120 |

21.5 |

29.5 |

|

150 |

100 |

195 |

120 |

23.5 |

31 |

|

150 |

150 |

255 |

125 |

28 |

35.6 |

|

200 |

80 |

175 |

145 |

30 |

37.9 |

|

200 |

100 |

200 |

145 |

|

38.8 |

|

200 |

150 |

255 |

150 |

37 |

45 |

|

200 |

200 |

315 |

155 |

43 |

50.5 |

|

250 |

100 |

200 |

170 |

42 |

49 |

|

250 |

150 |

260 |

175 |

48 |

61 |

|

250 |

200 |

315 |

180 |

54 |

63.5 |

|

250 |

250 |

375 |

190 |

55 |

71.5 |

|

300 |

100 |

205 |

195 |

59 |

66.5 |

|

300 |

150 |

260 |

200 |

70 |

80.5 |

|

300 |

200 |

320 |

205 |

72 |

84 |

|

300 |

300 |

435 |

220 |

81 |

106 |

|

350 |

100 |

210 |

225 |

67.5 |

78 |

|

350 |

150 |

260 |

230 |

79.6 |

95 |

|

350 |

200 |

320 |

235 |

85 |

98 |

|

350 |

300 |

380 |

240 |

106 |

122 |

|

350 |

350 |

495 |

250 |

116 |

133 |

|

400 |

100 |

210 |

245 |

81 |

92 |

|

400 |

150 |

270 |

250 |

90 |

111 |

|

400 |

200 |

325 |

255 |

98 |

114 |

|

400 |

300 |

440 |

270 |

119 |

140 |

|

400 |

400 |

560 |

280 |

142 |

167 |

|

450 |

150 |

270 |

280 |

111 |

128 |

|

450 |

200 |

330 |

280 |

122 |

131 |

|

450 |

300 |

445 |

295 |

144 |

160 |

|

450 |

400 |

560 |

305 |

168 |

188 |

|

450 |

450 |

620 |

310 |

181 |

203 |

|

500 |

150 |

275 |

300 |

131 |

145 |

|

500 |

200 |

330 |

310 |

145 |

148 |

|

500 |

300 |

450 |

320 |

165 |

179 |

|

500 |

400 |

565 |

330 |

187 |

210 |

|

500 |

500 |

680 |

340 |

221 |

242 |

|

600 |

150 |

280 |

350 |

188 |

184 |

|

600 |

200 |

340 |

360 |

201 |

187 |

|

600 |

300 |

455 |

370 |

208 |

223 |

|

600 |

400 |

570 |

380 |

243 |

259 |

|

600 |

600 |

800 |

400 |

335 |

337 |

• •

K14

Available in T Type and K Type;

Size: DN80-2000

|

Nominal Diameter |

L |

H |

Mass(kg) | ||

|

DN |

dn |

T Type |

K Type | ||

|

700 |

200 |

345 |

410 |

248 |

250 |

|

700 |

300 |

460 |

420 |

286 |

292 |

|

700 |

400 |

575 |

430 |

328 |

333 |

|

700 |

600 |

810 |

450 |

416 |

422 |

|

700 |

700 |

925 |

460 |

474 |

475 |

|

800 |

200 |

350 |

460 |

309 |

301 |

|

800 |

300 |

465 |

470 |

354 |

350 |

|

800 |

400 |

580 |

480 |

403 |

398 |

|

800 |

600 |

815 |

500 |

580 |

576 |

|

800 |

800 |

1045 |

525 |

632 |

618 |

|

900 |

200 |

355 |

510 |

382 |

370 |

|

900 |

400 |

590 |

530 |

493 |

484 |

|

900 |

600 |

820 |

550 |

747 |

739 |

|

900 |

800 |

1050 |

575 |

795 |

777 |

|

900 |

900 |

1170 |

585 |

826 |

806 |

|

1000 |

200 |

360 |

560 |

464 |

453 |

|

1000 |

400 |

595 |

580 |

592 |

584 |

|

1000 |

600 |

825 |

600 |

943 |

936 |

|

1000 |

800 |

1060 |

625 |

988 |

971 |

|

1000 |

1000 |

1290 |

645 |

1051 |

1033 |

|

1200 |

400 |

605 |

720 |

840 |

780 |

|

1200 |

600 |

840 |

740 |

1009 |

950 |

|

1200 |

800 |

1070 |

765 |

1198 |

1129 |

|

1200 |

1000 |

1300 |

785 |

1401 |

1331 |

|

1200 |

1200 |

1535 |

805 |

1644 |

1547 |

|

1400 |

600 |

1030 |

840 |

1679 |

1422 |

|

1400 |

800 |

1260 |

865 |

1910 |

1641 |

|

1400 |

1000 |

1495 |

885 |

2441 |

1886 |

|

1400 |

1200 |

1725 |

905 |

2795 |

2133 |

|

1400 |

1400 |

1960 |

930 |

3124 |

2436 |

|

1600 |

600 |

1040 |

940 |

2245 |

1806 |

|

1600 |

800 |

1275 |

965 |

2546 |

2073 |

|

1600 |

1000 |

1505 |

985 |

2851 |

2363 |

|

1600 |

1200 |

1740 |

1010 |

3663 |

2660 |

|

1600 |

1400 |

1970 |

1030 |

4066 |

2992 |

|

1600 |

1600 |

2200 |

1050 |

4474 |

3346 |

|

1800 |

600 |

1055 |

1040 |

- |

2272 |

|

1800 |

800 |

1285 |

1065 |

- |

2591 |

|

1800 |

1000 |

1520 |

1085 |

- |

2933 |

|

1800 |

1200 |

1750 |

1110 |

- |

3274 |

|

1800 |

1400 |

1980 |

1130 |

- |

3652 |

|

1800 |

1600 |

2215 |

1150 |

- |

4052 |

|

1800 |

1800 |

2445 |

1175 |

- |

4498 |

|

2000 |

600 |

1065 |

1140 |

- |

2793 |

|

2000 |

800 |

1300 |

1165 |

- |

3179 |

|

2000 |

1000 |

1530 |

1185 |

- |

3572 |

|

2000 |

1200 |

1760 |

1210 |

- |

3968 |

|

2000 |

1400 |

1995 |

1230 |

- |

4407 |

|

2000 |

1600 |

2225 |

1250 |

- |

4850 |

|

2000 |

1800 |

2460 |

1275 |

- |

5346 |

|

2000 |

2000 |

2690 |

1295 |

- |

5873 |

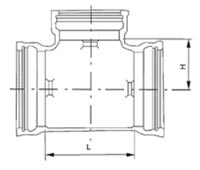

All Flanged Tee

K14

PN10, PN16 and PN25 are available

Size: DN80-2000

We are involved in the manufacture and supply of the ductile iron All Flanged Tee. We manufacture these with the premium quality raw materials. Our All Flanged Tee ensure high durability and strength. Our range of All Flanged Tees caters to various industrial requirements. We offer these All Flanged Tees in different sizes and lengths in order to meet the various requirements of our esteemed clients.

|

Nominal Diameter |

L |

H |

Mass(kg) | |||

|

DN |

dn |

PN10 |

PN16 |

PN25 | ||

|

80 |

80 |

330 |

165 |

15.8 |

15.8 |

15.8 |

|

100 |

80 |

360 |

175 |

18.4 |

18.4 |

19.6 |

|

100 |

100 |

360 |

180 |

19.5 |

19.5 |

21.0 |

|

150 |

80 |

440 |

205 |

29.0 |

29.0 |

31.0 |

|

150 |

100 |

440 |

210 |

30.0 |

30.0 |

32.5 |

|

150 |

150 |

440 |

220 |

32.5 |

32.5 |

36.5 |

|

200 |

80 |

520 |

235 |

42 |

41.5 |

46 |

|

200 |

100 |

520 |

240 |

43 |

42 |

47.5 |

|

200 |

150 |

520 |

250 |

46 |

45.5 |

51 |

|

200 |

200 |

520 |

260 |

49.5 |

49 |

56 |

|

250 |

100 |

700 |

275 |

68 |

67 |

75 |

|

250 |

150 |

700 |

300 |

68 |

67 |

74.8 |

|

250 |

200 |

700 |

325 |

76 |

75 |

85 |

|

250 |

250 |

700 |

350 |

82 |

81 |

93 |

|

300 |

100 |

800 |

300 |

94 |

93 |

105 |

|

300 |

150 |

800 |

325 |

97 |

96 |

109 |

|

300 |

200 |

800 |

350 |

102 |

101 |

114 |

|

300 |

300 |

800 |

400 |

116 |

115 |

131 |

|

350 |

100 |

850 |

325 |

116 |

122 |

139 |

|

350 |

150 |

850 |

325 |

118 |

125 |

143 |

|

350 |

200 |

850 |

325 |

121 |

128 |

146 |

|

350 |

300 |

850 |

425 |

138 |

147 |

170 |

|

350 |

350 |

850 |

425 |

142 |

151 |

176 |

|

400 |

100 |

900 |

350 |

143 |

154 |

177 |

|

400 |

150 |

900 |

350 |

148 |

157 |

181 |

|

400 |

200 |

900 |

350 |

148 |

159 |

184 |

|

400 |

300 |

900 |

450 |

167 |

176 |

204 |

|

400 |

400 |

900 |

450 |

174 |

191 |

225 |

|

450 |

100 |

950 |

375 |

177 |

193 |

216 |

|

450 |

150 |

950 |

375 |

180 |

196 |

220 |

|

450 |

200 |

950 |

375 |

183 |

199 |

224 |

|

450 |

300 |

950 |

475 |

199 |

215 |

244 |

|

450 |

400 |

950 |

475 |

210 |

230 |

264 |

|

450 |

450 |

950 |

475 |

216 |

240 |

275 |

|

500 |

100 |

1000 |

400 |

210 |

241 |

265 |

|

500 |

150 |

1000 |

400 |

215 |

244 |

268 |

|

500 |

200 |

1000 |

400 |

242 |

245 |

271 |

|

500 |

300 |

1000 |

500 |

235 |

263 |

292 |

|

500 |

400 |

1000 |

500 |

242 |

276 |

311 |

|

500 |

500 |

1000 |

500 |

252 |

297 |

332 |

|

600 |

150 |

1100 |

450 |

307 |

356 |

386 |

|

600 |

200 |

1100 |

450 |

305 |

358 |

388 |

|

600 |

300 |

1100 |

550 |

326 |

375 |

410 |

|

600 |

400 |

1100 |

550 |

329 |

387 |

427 |

|

600 |

600 |

1100 |

550 |

355 |

434 |

477 |

|

Nominal Diameter |

L |

H |

Mass(kg) | |||

|

DN |

dn |

PN10 |

PN16 |

PN25 | ||

|

700 |

200 |

650 |

525 |

258 |

298 |

363 |

|

700 |

300 |

760 |

540 |

344 |

370 |

439 |

|

700 |

400 |

870 |

555 |

343 |

379 |

453 |

|

700 |

600 |

1200 |

585 |

468 |

519 |

596 |

|

700 |

700 |

1200 |

600 |

477 |

523 |

617 |

|

800 |

200 |

690 |

585 |

352 |

390 |

491 |

|

800 |

300 |

800 |

600 |

440 |

478 |

582 |

|

800 |

400 |

910 |

615 |

441 |

484 |

593 |

|

800 |

600 |

1350 |

645 |

613 |

678 |

790 |

|

800 |

800 |

1350 |

675 |

657 |

715 |

862 |

|

900 |

200 |

730 |

645 |

436 |

484 |

607 |

|

900 |

400 |

950 |

675 |

541 |

594 |

726 |

|

900 |

600 |

1500 |

705 |

787 |

862 |

996 |

|

900 |

800 |

1500 |

735 |

835 |

901 |

1071 |

|

900 |

900 |

1500 |

750 |

853 |

924 |

1106 |

|

1000 |

200 |

770 |

705 |

546 |

629 |

787 |

|

1000 |

400 |

990 |

735 |

668 |

755 |

922 |

|

1000 |

600 |

1650 |

765 |

1007 |

1116 |

1287 |

|

1000 |

800 |

1650 |

795 |

1072 |

1191 |

1396 |

|

1000 |

1000 |

1650 |

825 |

1105 |

1229 |

1463 |

|

1200 |

400 |

1005 |

855 |

1008 |

1131 |

1302 |

|

1200 |

600 |

1240 |

855 |

1001 |

1256 |

1470 |

|

1200 |

800 |

1470 |

915 |

1291 |

1492 |

1687 |

|

1200 |

1000 |

1700 |

945 |

1494 |

1714 |

1941 |

|

1200 |

1200 |

1935 |

975 |

1806 |

1970 |

2269 |

|

1400 |

600 |

1550 |

980 |

1555 |

1818 |

2138 |

|

1400 |

800 |

1760 |

1010 |

1886 |

2041 |

2395 |

|

1400 |

1000 |

2015 |

1040 |

2131 |

2309 |

2692 |

|

1400 |

1200 |

2245 |

1070 |

2262 |

2431 |

2836 |

|

1400 |

1400 |

2478 |

1100 |

2545 |

2715 |

3173 |

|

1600 |

600 |

1600 |

1090 |

2167 |

2398 |

2767 |

|

1600 |

800 |

1835 |

1120 |

2452 |

2675 |

3079 |

|

1600 |

1000 |

2065 |

1150 |

2740 |

2986 |

3418 |

|

1600 |

1200 |

2300 |

1180 |

3058 |

3327 |

3781 |

|

1600 |

1400 |

2530 |

1210 |

3208 |

3444 |

3950 |

|

1600 |

1600 |

2760 |

1240 |

3586 |

3854 |

4385 |

|

1800 |

600 |

1655 |

1200 |

2694 |

2972 |

3467 |

|

1800 |

800 |

1885 |

1230 |

3023 |

3299 |

3828 |

|

1800 |

1000 |

2120 |

1260 |

3375 |

3699 |

4227 |

|

1800 |

1200 |

2350 |

1290 |

3740 |

4056 |

4636 |

|

1800 |

1400 |

2580 |

1320 |

3910 |

4190 |

4822 |

|

1800 |

1600 |

2815 |

1350 |

4328 |

4641 |

5298 |

|

1800 |

1800 |

3045 |

1380 |

4750 |

5086 |

5806 |

|

2000 |

600 |

1705 |

1310 |

3309 |

3642 |

4362 |

|

2000 |

800 |

1720 |

1340 |

3505 |

3796 |

4551 |

|

2000 |

1000 |

1940 |

1370 |

4112 |

4459 |

5243 |

|

2000 |

1200 |

2160 |

1400 |

4314 |

4644 |

5450 |

|

2000 |

1400 |

2380 |

1430 |

4966 |

5340 |

6198 |

|

2000 |

1600 |

2600 |

1460 |

5202 |

5567 |

6450 |

|

2000 |

1800 |

2820 |

1490 |

5668 |

6055 |

7001 |

|

2000 |

2000 |

3040 |

1520 |

6185 |

6599 |

7658 |

All Flanged Tee

K14

PN10, PN16 and PN25 are available

Size: DN80-2400

We are involved in the manufacture and supply of the ductile iron All Flanged Tee. We manufacture these with the premium quality raw materials. Our All Flanged Tee ensure high durability and strength. Our range of All Flanged Tees caters to various industrial requirements. We offer these All Flanged Tees in different sizes and lengths in order to meet the various requirements of our esteemed clients.

|

Nominal Diameter |

L |

H |

Mass(kg) | |||

|

DN |

dn |

PN10 |

PN16 |

PN25 | ||

|

80 |

80 |

330 |

165 |

15.8 |

15.8 |

15.8 |

|

100 |

80 |

360 |

175 |

18.4 |

18.4 |

19.6 |

|

100 |

100 |

360 |

180 |

19.5 |

19.5 |

21.0 |

|

150 |

80 |

440 |

205 |

29.0 |

29.0 |

31.0 |

|

150 |

100 |

440 |

210 |

30.0 |

30.0 |

32.5 |

|

150 |

150 |

440 |

220 |

32.5 |

32.5 |

36.5 |

|

200 |

80 |

520 |

235 |

42 |

41.5 |

46 |

|

200 |

100 |

520 |

240 |

43 |

42 |

47.5 |

|

200 |

150 |

520 |

250 |

46 |

45.5 |

51 |

|

200 |

200 |

520 |

260 |

49.5 |

49 |

56 |

|

250 |

100 |

700 |

275 |

68 |

67 |

75 |

|

250 |

150 |

700 |

300 |

68 |

67 |

74.8 |

|

250 |

200 |

700 |

325 |

76 |

75 |

85 |

|

250 |

250 |

700 |

350 |

82 |

81 |

93 |

|

300 |

100 |

800 |

300 |

94 |

93 |

105 |

|

300 |

150 |

800 |

325 |

97 |

96 |

109 |

|

300 |

200 |

800 |

350 |

102 |

101 |

114 |

|

300 |

300 |

800 |

400 |

116 |

115 |

131 |

|

350 |

100 |

850 |

325 |

116 |

122 |

139 |

|

350 |

150 |

850 |

325 |

118 |

125 |

143 |

|

350 |

200 |

850 |

325 |

121 |

128 |

146 |

|

350 |

300 |

850 |

425 |

138 |

147 |

170 |

|

350 |

350 |

850 |

425 |

142 |

151 |

176 |

|

400 |

100 |

900 |

350 |

143 |

154 |

177 |

|

400 |

150 |

900 |

350 |

148 |

157 |

181 |

|

400 |

200 |

900 |

350 |

148 |

159 |

184 |

|

400 |

300 |

900 |

450 |

167 |

176 |

204 |

|

400 |

400 |

900 |

450 |

174 |

191 |

225 |

|

450 |

100 |

950 |

375 |

177 |

193 |

216 |

|

450 |

150 |

950 |

375 |

180 |

196 |

220 |

|

450 |

200 |

950 |

375 |

183 |

199 |

224 |

|

450 |

300 |

950 |

475 |

199 |

215 |

244 |

|

450 |

400 |

950 |

475 |

210 |

230 |

264 |

|

450 |

450 |

950 |

475 |

216 |

240 |

275 |

|

500 |

100 |

1000 |

400 |

210 |

241 |

265 |

|

500 |

150 |

1000 |

400 |

215 |

244 |

268 |

|

500 |

200 |

1000 |

400 |

242 |

245 |

271 |

|

500 |

300 |

1000 |

500 |

235 |

263 |

292 |

|

500 |

400 |

1000 |

500 |

242 |

276 |

311 |

|

500 |

500 |

1000 |

500 |

252 |

297 |

332 |

|

600 |

150 |

1100 |

450 |

307 |

356 |

386 |

|

600 |

200 |

1100 |

450 |

305 |

358 |

388 |

|

600 |

300 |

1100 |

550 |

326 |

375 |

410 |

|

600 |

400 |

1100 |

550 |

329 |

387 |

427 |

|

600 |

600 |

1100 |

550 |

355 |

434 |

477 |

|

Nominal Diameter |

L |

H |

Mass(kg) | |||

|

DN |

dn |

PN10 |

PN16 |

PN25 | ||

|

700 |

200 |

650 |

525 |

258 |

298 |

363 |

|

700 |

300 |

760 |

540 |

344 |

370 |

439 |

|

700 |

400 |

870 |

555 |

343 |

379 |

453 |

|

700 |

600 |

1200 |

585 |

468 |

519 |

596 |

|

700 |

700 |

1200 |

600 |

477 |

523 |

617 |

|

800 |

200 |

690 |

585 |

352 |

390 |

491 |

|

800 |

300 |

800 |

600 |

440 |

478 |

582 |

|

800 |

400 |

910 |

615 |

441 |

484 |

593 |

|

800 |

600 |

1350 |

645 |

613 |

678 |

790 |

|

800 |

800 |

1350 |

675 |

657 |

715 |

862 |

|

900 |

200 |

730 |

645 |

436 |

484 |

607 |

|

900 |

400 |

950 |

675 |

541 |

594 |

726 |

|

900 |

600 |

1500 |

705 |

787 |

862 |

996 |

|

900 |

800 |

1500 |

735 |

835 |

901 |

1071 |

|

900 |

900 |

1500 |

750 |

853 |

924 |

1106 |

|

1000 |

200 |

770 |

705 |

546 |

629 |

787 |

|

1000 |

400 |

990 |

735 |

668 |

755 |

922 |

|

1000 |

600 |

1650 |

765 |

1007 |

1116 |

1287 |

|

1000 |

800 |

1650 |

795 |

1072 |

1191 |

1396 |

|

1000 |

1000 |

1650 |

825 |

1105 |

1229 |

1463 |

|

1200 |

400 |

1005 |

855 |

1008 |

1131 |

1302 |

|

1200 |

600 |

1240 |

855 |

1001 |

1256 |

1470 |

|

1200 |

800 |

1470 |

915 |

1291 |

1492 |

1687 |

|

1200 |

1000 |

1700 |

945 |

1494 |

1714 |

1941 |

|

1200 |

1200 |

1935 |

975 |

1806 |

1970 |

2269 |

|

1400 |

600 |

1550 |

980 |

1555 |

1818 |

2138 |

|

1400 |

800 |

1760 |

1010 |

1886 |

2041 |

2395 |

|

1400 |

1000 |

2015 |

1040 |

2131 |

2309 |

2692 |

|

1400 |

1200 |

2245 |

1070 |

2262 |

2431 |

2836 |

|

1400 |

1400 |

2478 |

1100 |

2545 |

2715 |

3173 |

|

1600 |

600 |

1600 |

1090 |

2167 |

2398 |

2767 |

|

1600 |

800 |

1835 |

1120 |

2452 |

2675 |

3079 |

|

1600 |

1000 |

2065 |

1150 |

2740 |

2986 |

3418 |

|

1600 |

1200 |

2300 |

1180 |

3058 |

3327 |

3781 |

|

1600 |

1400 |

2530 |

1210 |

3208 |

3444 |

3950 |

|

1600 |

1600 |

2760 |

1240 |

3586 |

3854 |

4385 |

|

1800 |

600 |

1655 |

1200 |

2694 |

2972 |

3467 |

|

1800 |

800 |

1885 |

1230 |

3023 |

3299 |

3828 |

|

1800 |

1000 |

2120 |

1260 |

3375 |

3699 |

4227 |

|

1800 |

1200 |

2350 |

1290 |

3740 |

4056 |

4636 |

|

1800 |

1400 |

2580 |

1320 |

3910 |

4190 |

4822 |

|

1800 |

1600 |

2815 |

1350 |

4328 |

4641 |

5298 |

|

1800 |

1800 |

3045 |

1380 |

4750 |

5086 |

5806 |

|

2000 |

600 |

1705 |

1310 |

3309 |

3642 |

4362 |

|

2000 |

800 |

1720 |

1340 |

3505 |

3796 |

4551 |

|

2000 |

1000 |

1940 |

1370 |

4112 |

4459 |

5243 |

|

2000 |

1200 |

2160 |

1400 |

4314 |

4644 |

5450 |

|

2000 |

1400 |

2380 |

1430 |

4966 |

5340 |

6198 |

|

2000 |

1600 |

2600 |

1460 |

5202 |

5567 |

6450 |

|

2000 |

1800 |

2820 |

1490 |

5668 |

6055 |

7001 |

|

2000 |

2000 |

3040 |

1520 |

6185 |

6599 |

7658 |

All Flanged 45° Angle Branches

K12

Type N and Type M

Size: DN80-800

We are involved in the manufacture and supply of the ductile iron All Flanged Branches. We manufacture these with the premium quality raw materials. Our All Flanged 45° Angle Branches ensure high durability and strength. Our range of All Flanged 45° Angle Branches caters to various industrial requirements. We offer these All Flanged 45° Angle Branches in different sizes and lengths in order to meet the various requirements of our esteemed clients.

|

Nominal Diameter DN |

Type |

L |

K |

Mass(kg) PN16 | |

|

DN |

dn | ||||

|

80 |

80 |

N |

500 |

375 |

21.0 |

|

100 |

100 |

N |

540 |

405 |

27.0 |

|

150 |

150 |

N |

640 |

480 |

46.4 |

|

200 |

200 |

N |

735 |

560 |

71 |

|

250 |

250 |

N |

830 |

640 |

105 |

|

300 |

300 |

N |

930 |

715 |

147 |

|

350 |

350 |

N |

- |

- |

168 |

|

400 |

400 |

N |

- |

- |

315 |

|

450 |

450 |

N |

- |

- |

338 |

|

500 |

500 |

N |

- |

- |

425 |

|

600 |

600 |

N |

- |

- |

624 |

|

700 |

700 |

- |

- |

- |

876 |

|

800 |

800 |

- |

- |

- |

1200 |

• •

All Flanged Radial Tees

K14

PN16

Size: DN80-600

We are involved in the manufacture and supply of the ductile iron All Flanged Tee. We manufacture these with the premium quality raw materials. Our All Flanged Tee ensure high durability and strength. Our range of All Flanged Tees caters to various industrial requirements. We offer these All Flanged Radial Tees in different sizes and lengths in order to meet the various requirements of our esteemed clients.

|

Nominal Diameter |

L |

A |

B |

r |

Mass(kg)PN16 | |

|

DN |

dn | |||||

|

80 |

80 |

545 |

165 |

380 |

330 |

23.0 |

|

100 |

100 |

580 |

180 |

400 |

340 |

30 |

|

150 |

150 |

670 |

220 |

450 |

385 |

52 |

|

200 |

200 |

760 |

260 |

500 |

430 |

80 |

|

250 |

250 |

900 |

350 |

550 |

475 |

121 |

|

300 |

300 |

1000 |

400 |

600 |

515 |

163 |

|

350 |

350 |

1100 |

450 |

650 |

560 |

222 |

|

400 |

400 |

1200 |

500 |

700 |

605 |

299 |

|

450 |

450 |

1300 |

550 |

750 |

650 |

394 |

|

500 |

500 |

1400 |

600 |

800 |

690 |

489 |

|

600 |

600 |

1600 |

700 |

900 |

780 |

739 |

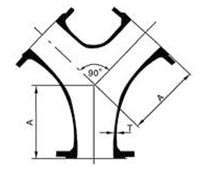

All Flanged 'Y' Tees

K14

Size: DN80-700

We are involved in the manufacture and supply of the ductile iron All Flanged Tee. We manufacture these with the premium quality raw materials. Our All Flanged Tee ensure high durability and strength. Our range of All Flanged Tees caters to various industrial requirements. We offer these All Flanged 'Y' Tees in different sizes and lengths in order to meet the various requirements of our esteemed cli

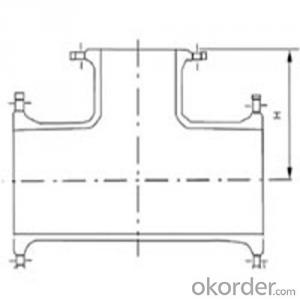

Double Socket Level Invert Tee With Flanged Branch

K14

Available in T Type and K Type;

We are involved in the manufacture and supply of the Double Socket Level Invert Tees. We manufacture these with the premium quality raw materials. Our Double Socket Level Invert Tees ensure high durability and strength. Our range of Double Socket Level Invert Tees caters to various industrial requirements. We offer these Double Socket Level Invert Tees With Flanged Branch in different sizes and lengths in order to meet the various requirements of our esteemed clients.

|

DN |

L |

H |

Mass(kg) | |||||

|

T |

K | |||||||

|

PN10 |

PN16 |

PN25 |

PN10 |

PN16 |

PN25 | |||

|

200×80 |

245 |

250 |

39.5 |

39.5 |

39.5 |

43.0 |

43.0 |

43.0 |

|

250×80 |

250 |

275 |

49.5 |

49.5 |

49.5 |

54.0 |

54.0 |

54.0 |

|

300×80 |

255 |

300 |

62.0 |

62.0 |

62.0 |

73.5 |

73.5 |

73.5 |

|

350×100 |

280 |

325 |

83.0 |

83.0 |

83.5 |

90.5 |

90.5 |

91.0 |

|

400×100 |

280 |

350 |

97.5 |

97.5 |

98.0 |

107 |

107 |

108 |

|

450×100 |

285 |

375 |

115 |

115 |

116 |

125 |

125 |

126 |

|

500×100 |

290 |

400 |

134 |

134 |

134 |

143 |

143 |

144 |

|

600×100 |

295 |

450 |

173 |

173 |

173 |

183 |

183 |

183 |

|

700×150 |

360 |

500 |

255 |

255 |

256 |

255 |

255 |

256 |

|

800×150 |

365 |

550 |

- |

- |

- |

310 |

310 |

311 |

|

900×150 |

370 |

600 |

- |

- |

- |

382 |

382 |

383 |

|

1000×200 |

435 |

650 |

- |

- |

- |

501 |

501 |

503 |

|

1100×200 |

440 |

700 |

- |

- |

- |

584 |

584 |

586 |

|

1200×200 |

445 |

750 |

- |

- |

- |

679 |

679 |

681 |

|

1400×200 |

460 |

850 |

- |

- |

- |

939 |

939 |

940 |

|

1500×200 |

465 |

900 |

- |

- |

- |

1062 |

1062 |

1064 |

|

1600×400 |

700 |

950 |

- |

- |

- |

1472 |

1476 |

1487 |

|

1800×400 |

715 |

1050 |

- |

- |

- |

1872 |

1876 |

1887 |

|

2000×400 |

725 |

1150 |

- |

- |

- |

2320 |

2325 |

2336 |

|

2100×400 |

730 |

1200 |

- |

- |

- |

2539 |

2544 |

2555 |

|

2200×400 |

735 |

1250 |

- |

- |

- |

2802 |

2807 |

2818 |

|

2400×400 |

750 |

1350 |

- |

- |

- |

3347 |

3351 |

3362 |

|

2600×400 |

760 |

1450 |

- |

- |

- |

4136 |

4140 |

4151 |

Specifications:

ductile iron tee

We manufacture ISO2531 ductile iron tee fitting according to ISO2531 or BS EN 545.

ductile iron tee

We supply ISO2531 ductile iron tee fitting according to ISO2531 or BS EN545, the coating of the fitting is zinc and bitumen or epoxy.

1, Standards : ISO2531, ISO4422, EN545 , EN598 , BS4772

2,material : GGG500-7 or other Ductile iron .

3, coating : Fusion bonded epoxy coating ; cement lining inside and zinc primer andbitumen painting outside ; bitumen painting inside and outside ; red anti-rustcoating .

4 , package : wooden cases with plastic layer , wooden pallets with plastic layer, steel crates .

5, accessories such as gaskets , bolts and nuts available upon request .

6, flanged pipe fittings , double flange pipe, single flange pipe, push-on Tyton socket fittings , Ductile iron/PVC fittings, K type bolted gland fittings .

Packing & Delivery:

| Packaging Detail: | wooden case or pallets or as buyer's request |

| Delivery Detail: | within 15 days |

Usage:

To branch pipe tee joint in the main line.

- Q: Press the hydraulic pipe fittings standard need to do what procedures

- Be sure to grasp the reasonable degree of withholding, with joint core hole shrinkage degree as the standard, GB joints under compression compression joints under ordinary small 0.1~0.4mm, small 0.1~2mm. Because the hose and the joint coat of different manufacturers, such as the GB standard for most northern rubber hose production plant, 602 standard for the south, foreign SAE standard, the factory hose, joint specific size, material may not be the same, so the buckling parameter table data for reference only, the specific size should be withheld according to the experimental pressure.

- Q: How to identify the pipe joint thread quickly and accurately?

- 1 use a thread gauge to check the gauge of the pipe joint, which is the most accurate.2, you can also use special tools, taps (for female pipe joints) and wrench (for pipe fittings), which is a tool for making pipe joints. Try it on and see if it's easy to screw in. If it is easy to screw in, you can determine the specifications of the unknown pipe thread according to the specifications of the known taps and wrench marks.

- Q: I straighten it nearly everyday, and dye it. And it's starting to feel like straw, I use moisture conditioner and shampoo, by Aussie, but it isn't doing anything. What do you use to keep your hair hydrated? Something other than, don't dye it, or don't straighten it.thanks [:x

- Paul make sure fitting is dry inside and your using the right flux.A rose bud will work but could burn the fittings if your not careful.Mapp should be plenty of heat for that size.I use propane on 1 all the time.They willnot solder if there wet inside.

- Q: I suck at this stuff. I have an F and grades close really soon.1. Potential energy is the energy of?2. Kinetic energy depends on?3. Gravitational potential energy depends on?4. 5 renewable resources and 5 nonrenewable resources.5. What kind of energy is stored in a stretched rubber band?6.At what point does a roller coaster have the greatest potential energy?Help if you can please. I'll answer any question you want if I can!!Thank you. (:

- You forgot to to give us a picture of the crossword.

- Q: I was driving last night, and wasn't paying attention to where I was going in a parking lot and hit and knocked over a fire hydrant I didn't really notice what I did (I thought I just hit the curb) there was no water running to it yet I guess. so I drove away the next day I noticed my bumper was bent and had some paint on it. I know somebody had to'v got my plate can I get in serious trouble for this, if so what?

- Yes, you can fire them. Of course, they have every right to make you pay for the services they have already provided for you. In other words, you can't fire them now and not expect to owe them anything.

- Q: is it water. or something else

- Catch up on your housework - that will warm you up.

- Q: What's the meaning of the plumbing PVC pipe joint specification "1/2" "X12" and "1/2" "x18"?

- First specification 1/2 "X12": 1/2 inches in diameter and 12 inches in length.Second specifications 1/2 "x18": 1/2 inches in diameter and 18 inches in length.

- Q: Okay there is this cop who I always see around my office neighbor, gave me ridiculous $115 fine for parking in-front of fire hydrant couple of seconds. I just realize he always park there to get (guess what!) dunkin donuts. This is ridiculous! I think he gave me a ticket before because he thought i violated his spot or something! it was all his EGO! can I record him and send it to MV violation department? I mean he is not above the law.

- Try to hit it square and it's just a big bump, most speed bumps have a low/no spot between the bumps for a bike or rain water to get thru. I'm surprised to hear that you broke off the stand, it shouldn't have even hit.

- Q: In January Unemployment was at 8.6%. Any one want this Roller Coaster ride from the Rubber Band man for the next four years. Not ME, I happen to like Living with Food to Eat. Maybe Fluke and Obama should elope in Aruba. Now that's a thought. Sources:Love Roller Coaster - The Ohio PlayersUnemployment in the Bldg Construction Industry has been at 13% for the last 3 years - Ken Langone Founder of Home DepotRubber Band Man - The Spinners

- It sounds like a perfect tank for him. These fish like to fight with other beta's so I think he'll enjoy seeing his reflection plus he'll be more active.

- Q: I have 2 small children. And i am wanting to buy a few fire proff blankets for my home. Now if there were a fire on the floor would i be able to throw that blanket on the floor to reach my child and could i throw that blanket around us to help prevent us from catching on fire ?? Im not sure exactly how they work. Where would be a good place to buy really.good quality one that will work in case of emergency.

- The resistance of the system is called head loss or friction loss. It varies with the flow rate and is not in any way a static event. Static pressure refers to the pressure in the system when it is not flowing. Static mean stationary.

1. Manufacturer Overview

| Location | Liaoning, China |

| Year Established | 1994 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Mid East, Africa, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 500 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ductile Iron Tee

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton pc

- Supply Capability:

- 50,000 Ton Per Year pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords