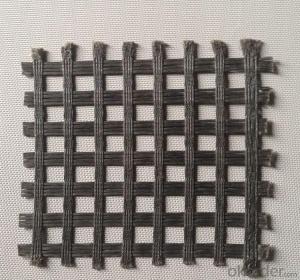

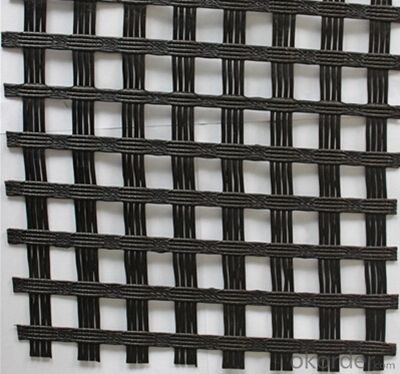

Polyester Woven Geogrids - Lyester Geogrid Composite for Coal Mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 1800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Polyester Geogrid description :

Made of polyester PET Fiber by weaving technology and coating treatment, it can bear high tensile strength .This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

Features of Polyester Geogrid for coal mine:

High strength ,low elongation, heat resisitant, high modulus ,light weight, good flexibility,anti-erosion,

Application of of Polyester Geogrid for coal mine :

Make reinforce treatment for various of soft soil foundation to evenly distribute load stress and reduce unevensettlement , it is easy to wash coal . used in highway ,railway,port,airport, municipacl and projects of supporting in the recovery working face of coal mined and ladeway in the coal mine .

Specification of Polyester Geogrid for coal mine

25-25KN,30-30KN,50-50KN,80-80KN,100-100KN,120-120KN

Width : 1M,2M,3M,4M.

Length: 50m,100,

Color: black

Packaging & Delivery of Polyester Geogrid for coal mine Each roll is wrapped in a woven bag then into container Or Packed as customers' requests.

Production periods of Polyester s Geogrid for coal mine : within 10 days after receiving the deposit

Introduction of CNBM

China National Building Materials (Group) Corporation (CNBM) is a state-owned enterprise in charge of administrative affairs in China building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of RMB 25 billion and a total staff of 30,000. Now CNBM owns more than 200 subsidiaries in and abroad the country, including wholly-owned corporations and joint ventures.

FAQ of geosynthetics :

What is geosynthetics ?

Geosynthetics form a perfect erosion control fabric used extremely widely in civil engineering to stabilize and reinforce slopes and soil under or next to roads, railways, dams, water reservoirs etc.. They can be easily applied which minimizes the time of construction, as well as they limit the resources and materials necessary.

What kinds of geosynthetics we have ?

Non-woven geotextile, geogrids, geocells, GCL, Geomembranes, Geonets, Geocomposites etc .

What is the geosynthetics used for ?

Hydraulic

Lagooning and Water Treatment, Ornamental Ponds, Golf Courses

Aquaculture and Desalination,Water Lagoons,Tanks, Reservoirs, Liquid Waste,Floating Cover Solutions, Drainage and Filtration

Environment

Tailing ponds, Leach mining,Landfills,Landfill Capping,Protection against corrosion,Vertical Barriers

Civil Works

Erosion Control,Secondary Containment,Tunnels,Linear and Surface Works,Consolidation of Margins,Soil Reinforcement,Soil Separation.

Building - Parkings,Roofing,Soundproofing

- Q: What is the action mechanism of OKorder geogrid

- Glass fiber geogrid / glassgrid mechanism of reflective cracking is due to the old concrete surface layer in the vicinity of the joint or crack of large displacement caused by the asphalt overlay above appear stress concentration caused by the. Glass fiber geogrid has been developed rapidly in recent years, and is widely used in asphalt pavement, especially used in asphalt overlay to reduce reflection cracks. Texas Traffic College of AM University in Canada with its unique overlay tester of glass fiber geogrid reinforced cover did a lot of tests and experiments show that the reinforced asphalt specimen cracking resistance than the unreinforced specimens two times. Wollongong Municipal Bureau of New South Wales, Australia has conducted on-site tests of glass fiber geogrid, PP geogrid, geotextile and thickness of asphalt concrete surface layer of reflection crack control products, the conclusion is glass fiber geogrid laying convenience, control effect of reflection crack is the most significant, and the cost is moderate. Therefore we should promote the application. Due to the reinforcement effect of glass fiber geogrid on asphalt overlay, so it can be in the premise of effective control of reflection cracks, reduce the asphalt overlay thickness (with and without laying fiberglass geogrid, compared) reduce the cost, and achieved good economic benefit.

- Q: What are the advantages of using geogrids?

- Geogrids offer several advantages in civil engineering and construction projects. Firstly, they enhance soil stability and reinforce weak soils, preventing soil erosion and improving load-bearing capacity. Secondly, geogrids can reduce construction costs by allowing for the use of locally available and lower-quality materials instead of expensive fill materials. Additionally, they provide long-term durability, resistance to chemical degradation, and high tensile strength, ensuring the longevity and structural integrity of the project. Moreover, geogrids are easy to install, lightweight, and flexible, making them convenient for various applications and reducing labor requirements. Overall, using geogrids results in improved soil performance, cost-effectiveness, and efficient construction processes.

- Q: How do geogrids improve the performance of flexible pavements?

- Geogrids improve the performance of flexible pavements by enhancing their strength and stability. They provide reinforcement and prevent the spreading of cracks and ruts, increasing the pavement's resistance to traffic loads. Additionally, geogrids help to distribute the load more evenly across the pavement, reducing the potential for deformation and extending its lifespan.

- Q: What is a geogrid?

- A geogrid is a type of geosynthetic material that is used to reinforce soil or other materials in civil engineering applications. It is typically made of polymer materials and has a grid-like structure that provides tensile strength and enhances the stability of the soil or other materials it is placed within.

- Q: Can geogrids be used in reinforcement of dams and levees?

- Yes, geogrids can be used in the reinforcement of dams and levees. Geogrids are highly durable and can provide tensile strength to the soil, enhancing its stability and preventing erosion. By incorporating geogrids into the construction of dams and levees, the structures can better withstand the forces exerted by water pressure and natural disasters.

- Q: What are the types of Geogrid

- There are many types of geogrid is about tgsg / convex node tgsg / whole tgsg / glass fiber geogrid

- Q: Can geogrids be used in temporary construction platforms for heavy equipment?

- Yes, geogrids can be used in temporary construction platforms for heavy equipment. Geogrids are strong and durable, providing stability and reinforcement to the ground. They can distribute the weight of heavy equipment, prevent soil erosion, and improve load-bearing capacity, making them suitable for temporary construction platforms.

- Q: Can geogrids be used in reinforcement of embankments over soft soils?

- Yes, geogrids can be used in the reinforcement of embankments over soft soils. Geogrids are commonly used in civil engineering to provide stability and strength to soil structures, including embankments. By distributing the load and reducing lateral movement, geogrids can effectively reinforce embankments over soft soils, preventing slope failure and improving overall stability.

- Q: What are the specifications of the geogrid

- Geogrid is divided into plastic geogrid

- Q: Do geogrids provide reinforcement to geosynthetic clay liners in waste containment facilities?

- Yes, geogrids can provide reinforcement to geosynthetic clay liners in waste containment facilities. Geogrids are commonly used in conjunction with geosynthetic clay liners to enhance their tensile strength and prevent their displacement. This reinforcement helps to improve the overall stability and performance of waste containment facilities.

Send your message to us

Polyester Woven Geogrids - Lyester Geogrid Composite for Coal Mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 1800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords