Race Car Body Aluminum Sheets - 1100 1050 2024 3003 5052 6061 6082 7021 Alloy Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Information:

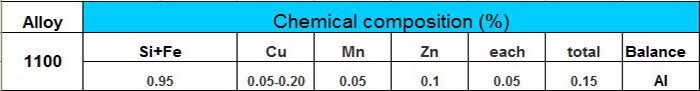

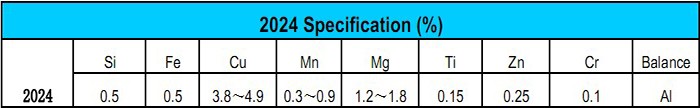

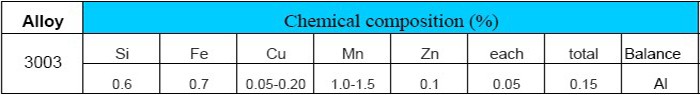

1.Alloy: 1100 1050 2024 2017 3003 5052 6061 6063 7075 7021 etc

2.Temper:O H112 H12 H14 H16 T3 T4 T6 T651 etc

3.Dimension based on customer requirements

4.Good quality choose us

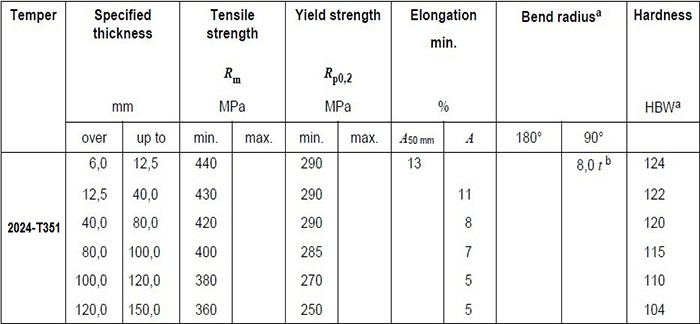

Chemical Composition:

Technical Specification:

Packaging & Delivery

| Packaging Details: | Wooden Pallet, Wooden Case, As Customzed, etc. |

| Delivery Detail: | 15 to 25 days depends on actual order |

Our Services

1) Reply within 12 hours

2) Free samples provided

3) On-site production following-up

4) Loading inspection with container fixing

5)Third party inspection at your request

Company Information

Advanced equipment and strict management both contribute to the excellent quality of products. Our main products are all kinds of cold rolling and hot rolling aluminum sheet, coil, checkered plate, embossed plate, aluminum foil, aluminum disc, aluminum profile, painted aluminum sheet and coil. Our products have various size choices with thickness from 0.008mm to 350mm, width from 200mm to 2300mm and length below 12m. Our products are sold to all over the world, including South America, North America, Europe, Middle-East, South-East Asia, Africa etc and used in various fields such as construction, decoration, automobile, electronic, machinery, boat construction, aeronautics&astronautics, cookware, packing etc.

Adhering to the principle of “ Surviving with quality and developing with credibility”, CNBM hopes to work with all customers for a better future.

FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 5 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4) Why YONGHONG?

With us, you get most competitive price, guranteened quality with assured delivery time and after sales service

- Q: Can aluminum sheets be perforated?

- Indeed, it is possible to perforate aluminum sheets. Perforating entails either punching holes or generating a pattern of holes in a material. Aluminum, being a flexible and adaptable metal, can be easily perforated through a variety of techniques like punching, drilling, or laser cutting. The perforation of aluminum sheets can have numerous applications, including facilitating airflow, reducing weight, improving aesthetics, or constructing filtration systems. The dimensions, form, and layout of the perforations can be tailored to satisfy particular demands and design preferences. In summary, perforating aluminum sheets can effectively enhance their functionality and visual allure.

- Q: What is the thickness of the aluminum sheets?

- Depending on the specific product or application, the thickness of the aluminum sheets may vary. Aluminum sheets come in a diverse range of thicknesses, typically varying from 0.006 inches (0.15 mm) to 0.25 inches (6.35 mm) or possibly even thicker. The suitable thickness will be determined by the specific requirements and intended usage of the aluminum sheet.

- Q: What are the special coatings or treatments available for enhancing the properties of aluminum sheets?

- <p>Yes, there are several special coatings and treatments that can be applied to aluminum sheets to enhance their properties. These include anodizing, which creates a protective oxide layer, powder coating for a durable and colorful finish, and thermal spraying for improved wear resistance. Other treatments involve chemical conversion coatings, such as chromate conversion, which provides corrosion resistance, and various types of plating like electroplating or hot-dip galvanizing for added strength and protection. These treatments can significantly improve the appearance, durability, and performance of aluminum sheets in various applications.</p>

- Q: What is the fatigue strength of 101 aluminum sheets?

- The maximum stress level that 101 aluminum sheets can endure without experiencing fatigue failure is known as their fatigue strength. Typically, fatigue strength is determined by subjecting the material to repeated cyclic loading until failure occurs. However, it is important to understand that the fatigue strength can vary depending on various factors, such as the thickness of the sheet, its surface condition, heat treatment, and other mechanical properties. Therefore, it is not possible to provide an accurate value for the fatigue strength of 101 aluminum sheets without specific information about these variables. To obtain the fatigue strength of 101 aluminum sheets, it is recommended to refer to the material's technical datasheet or contact the manufacturer or supplier for precise information. They can provide details on the fatigue properties, including the endurance limit or the stress level at which the material can withstand an unlimited number of cycles without experiencing fatigue failure.

- Q: Our production needs a large number of plating aluminum plate, consult domestic and imported aluminum plate difference?

- Guangdong Huayuan prosperous is the largest aluminum plate supplier 021-56808701, in Shanghai / Tianjin / Chongqing have logistics and storage, domestic aluminum plating surface coating treatment is less than imports, stamping coating is easy to fall,

- Q: Is it suitable to use aluminum sheets in outdoor settings where they will be subjected to weather conditions?

- <p>Yes, aluminum sheets can be used for outdoor applications, even when exposed to weathering. Aluminum is a durable and corrosion-resistant material, which makes it suitable for outdoor use. It does not rust like iron or steel and can withstand various weather conditions. However, it's important to use aluminum alloys specifically designed for outdoor use, and to apply protective coatings or finishes to enhance its resistance to weathering and extend its lifespan.</p>

- Q: What are the different types of surface treatments available for aluminum sheets?

- There are several different types of surface treatments available for aluminum sheets, including anodizing, powder coating, painting, polishing, and brushing. These treatments can enhance the appearance, durability, corrosion resistance, and overall performance of the aluminum sheets.

- Q: How are aluminum sheets measured and specified?

- Aluminum sheets are typically measured and specified based on their thickness, width, and length. The thickness is commonly expressed in gauge or millimeters, while the width and length are provided in inches or millimeters. Additionally, the alloy composition and temper of the aluminum sheet may also be specified to meet specific requirements.

- Q: How do I join aluminum sheets together?

- There are several methods you can use to join aluminum sheets together, depending on the specific application and desired outcome. Here are a few common techniques: 1. Riveting: Riveting involves using rivets, which are small metal fasteners, to join the aluminum sheets. This method requires drilling holes into the sheets and then inserting the rivets, which are then permanently secured by deforming or compressing them. Riveting is a durable and widely used method for joining aluminum sheets. 2. Welding: Aluminum welding can be done using various techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), or laser welding. These methods melt the aluminum at the joint, allowing it to fuse and form a strong bond when cooled. Welding requires specialized equipment and expertise, but it provides a robust and permanent joining solution. 3. Adhesive bonding: This method involves using industrial-grade adhesives specifically designed for bonding aluminum. The adhesive is applied to the surfaces to be joined, and then the sheets are pressed together and allowed to cure. Adhesive bonding offers a clean and aesthetically pleasing joint, but it may not be suitable for high-stress applications. 4. Mechanical fasteners: Using screws, bolts, or nuts is another option to join aluminum sheets. This method involves drilling holes in the sheets and using fasteners to secure them together. Mechanical fasteners provide a strong and adjustable joint, making it easier to disassemble if needed. Before selecting a joining method, consider factors such as the application's strength requirements, appearance, ease of assembly, and disassembly. Additionally, it is essential to follow safety guidelines and consider seeking professional advice if you are unsure about which method to use or lack experience with joining aluminum sheets.

- Q: what's the difference between aluminum sheet detergent and central air-condition detergent?

- Central air condition cleaning includes air-cooled condenser cleaning and water-cooling condenser cleaning, if it’s air-cooled condenser cleaning, you can use aluminum sheet detergent.

Send your message to us

Race Car Body Aluminum Sheets - 1100 1050 2024 3003 5052 6061 6082 7021 Alloy Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords