Light Weight PVC PU Conveyor Belt Wood Application

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Weight PVC PU Conveyor Belt Wood Application

Description of PVC Conveyor Belt:

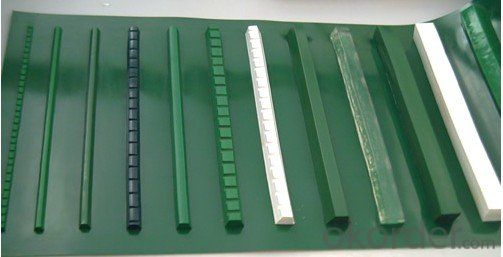

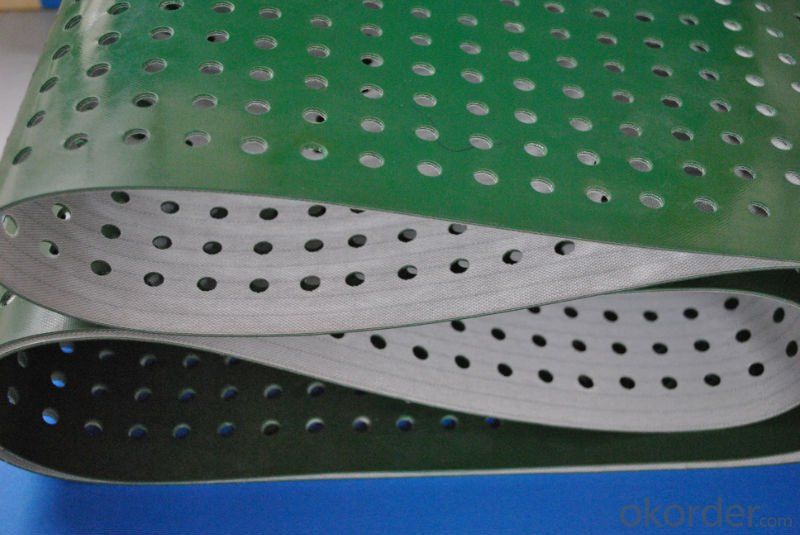

The wood processing belt that CNBM produce have the characterics of low elongation, pending, low nise, stable size, durable, wear-resisting.This kind of belt are used different material, decorative pattern and high strength of the fabric to increase stability and strength.Products can be widely used in plywood, fiberboard, composite board production line and all kinds of woodworking machinery equipment.

With advanced technology and equipments, we could offer an extensive line of light weight conveyor belting, now our belts are widely used in airports, postal automation, parcel handling, treadmills, packaging and wrapping, confectionery industry, food processing industry, paper printing industry and so on..

Feature of PVC Conveyor Belt:

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Working temperature ranges from -10 to 80Deg.C

| code | Top cover | Bottom Cover | Thick | Characteristics | Fabrics | ||||

| Material | Colour | Surface | Material | Colour | Surface | mm | Plies | ||

| PVC conveyor belt | |||||||||

1/10 S/P W | PVC | White | Smooth | - | Natural | Fabric | 1.0 | Antistatic | 1 |

1/12 S/S BK | PVC | Black | Smooth | PVC | Black | Smooth | 1.2 | 1 | |

1/16 D/STF BK TM | PVC | Black | Diamond | - | Natural | Strong Fabric | 1.6 | Tread mill | 1 |

2/12 P/P W | Fabric | Natural | Fabric | Fabric | Natural | Fabric | 1.2 | Antistatic | 2 |

2/18 P/P W | Fabric | White | Fabric | - | Natural | Fabric | 1.8 | Antistatic | 2 |

2/20 D/P AG | PVC | Apple Green | Diamond | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/2O S/P AG | PVC | Apple Green | Smooth | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/20 S/P PG | PVC | Petrol Green | Smooth | - | Natural | Fabric | 2.0 | No-antistic | 2 |

2/20 M/P BK | PVC | Black | Matt | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/20 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 2.0 | FDA | 2 |

2/20 S/P W | PVC | White | Smooth | - | Natural | Fabric | 2.0 | 2 | |

2/20 S/P BK | PVC | Black | Smooth | - | Natural | Fabric | 2.0 | 2 | |

2/25 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 2.5 | FDA | 2 |

2/30 S/FF PG | PVC | Petrol Green | Smooth | - | Natural | Flexible Fabric | 3.0 | Cold-Resistant | 2 |

2/30 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 3.0 | FDA | 2 |

2/30 S/P AG | PVC | Apple Green | Smooth | - | Natural | Fabric | 3.0 | Antistatic | 2 |

2/30 LR/SF AG | PVC | Apple Green | Longitudinal Lib | - | Natural | Silent Fabric | 3.0 | 2 | |

2/30 S/D W FDA | PVC | White | Smooth | PVC | White | Diamond | 3.0 | FDA | 2 |

2/30 S/D W | PVC | White | Smooth | PVC | White | Diamond | 3.0 | 2 | |

2/30 S/D AG | PVC | Apple Green | Smooth | PVC | Apple Green | Diamond | 3.0 | Antistatic | 2 |

2/38 S/P W | PVC | White | Smooth | - | Natural | Fabric | 3.8 | 2 | |

2/46 TS/P AG | PVC | Apple Green | Saw Tooth | - | Natural | Fabric | 4.6 | Antistatic | 2 |

2/50 RT/P AG | PVC | Apple Green | Rough Top1 | - | Natural | Fabric | 5.0 | No-antistic | 2 |

3/30 C/C W | Cotton | Natural | Cotton | Cotton | Natural | Cotton | 3.0 | 2ply cotton 1ply fabric | 3 |

3/40 S/P TAN | PVC | TAN Colour | Smooth | - | Natural | Fabric | 4.0 | No-antistic | 3 |

3/50 S/D AG | PVC | Apple Green | Smooth | PVC | Apple Green | Diamond | 5.0 | Antistatic | 3 |

3/40 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 4.0 | FDA | 3 |

| PU conveyor belt | |||||||||

1/08 S/P W U FDA | PU | White | Smooth | - | Natural | Impreg-nated | 0.8 | Antistatic | 1 |

2/15 M/P W U FDA | PU | White | Matt | - | Natural | Impreg-nated | 1.5 | Antistatic | 2 |

2/14 M/P PG U FDA | PU | Petrol Green | Matt | - | Natural | Impreg-nated | 1.4 | Antistatic | 2 |

2/21 S/P W U FDA | PU | White | Smooth | - | Natural | Fabric | 2.1 | Antistatic | 2 |

2/21 S/P W U KE | PU | White | Smooth | - | Natural | Fabric | 2.1 | Knife Edge Application | 2 |

2/30 S/P

W U FDA | PU | White | Smooth | - | Natural | Fabric | 3.0 | Antistatic | 2 |

Pictures of PVC Conveyor Belt

Pls contact me freely if any inquiry or questions,thank you!

- Q: What gum does rubber and metal stick together?

- JL-480 black rubber instant glue: medium viscosity, high strength, etc. used for inert surface, bonding, porous, acid, vibration and heat resistance, rubber, metal, plastic bonding. The utility model can be used for large gaps and more dispensing. High viscosity, impact resistance. The curing is slow, the curing has toughness, and the adhesive force is strong. After bonding, the adhesive surface can reach two and the adhesive surface dissolves as a whole. It is a shock resistant instant adhesive, which has better seismic and stripping strength than other series. Widely used, bonding rubber, plastic, and metal as adhesive for impact resistance. It is more flexible than conventional adhesive.

- Q: How can I make rubber products brighter?

- Special release agent for rubber products, release agent.Mold release agent is an interface coating used on two surfaces that are easy to adhere to each other. It can make the surface of the material easy to break off, smooth and clean. Mold release agent is used in various molding processes, such as glass fiber reinforced plastics, metal die casting, polyurethane foam and elastomer, injection molding thermoplastic, vacuum foaming sheet and extrusion section. In molding, sometimes other plastics, such as plasticizers, leak to the interface, and then a surface remover is needed to remove it.

- Q: How to maintain and store the rubber material?

- Rubber itself is a shelf-life, you can ask the supplier to warranty, above all, as fillers, such as calcium carbonate, carbon black, long time no problem, also have a shelf life of antioxidant promoter, especially individual species. When storing, pay attention to fire prevention, moisture-proof, away from the high temperature, avoid direct sunlight, of course, the general "first in first out" is a must follow the truth.

- Q: How to distinguish between good and bad silicone rubber gasket?

- Hardness and elongation stress reflect the rigid (stiffness) index of rubber material, and they are the necessary force for silica gel products to produce certain deformation. It is also a way to distinguish the quality of silica gel products.

- Q: Advantages and disadvantages of rubber products

- Styrene butadiene rubber SBR(Styrene Butadiene Copolymer) and butadiene styrene copolymers, compared with natural rubber of uniform quality, less foreign body, has better wear resistance and aging resistance, but the mechanical strength is weak, can be combined with natural rubber mixing. Non - oily material advantages: low cost, good water resistance, hardness below 70 with good elasticity, high hardness with poor shortcomings: compression, does not recommend the use of ozone, acid, oil, oil and fat ester and most hydrocarbons. Widely used in tire industry, shoes, cloth and conveyor belt industry etc..

- Q: What is the size of the scorch time of the rubber?

- Rubber scorch characteristics usually use 120 degrees Mooney scorch time Ts said, also available vulcameter determining curing curve on the T10 or TA1, TA2 said, the scorch time and process, the rubber accelerator process conditions, the hardness of the rubber material and rubber material return use and other factors. Generally soft rubber is 10-20min; most of the stock (excluding high filling hard or high temperature 35-80min) is 20-35min; the high filling hard material is.

- Q: Comparison of physical properties of HNBR rubber material with other rubber materials

- Hydrogenated nitrile rubber, referred to as "HNBR" or "H-NBR". It is a new variety of nitrile rubber (NBR).

- Q: How to identify the tire rubber is raw or cooked

- Rubber is a kind of polymer material with high elasticity, is the parent material manufacturing of rubber products, generally refers to the rubber unvulcanized. A nearly neutral liquid produced by a rubber tree and added with 0.05%~0.1% ammonia water to make latex (for a short period of time). Most of the latex need processed dry glue, all kinds of natural rubber is often said.

- Q: What is the difference between PVC rubber and ordinary rubber?

- PVC has strong resistance to oxidizing agents, reducing agents and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid, and it is also not suitable for contact with aromatic hydrocarbons and chlorinated hydrocarbons.

- Q: How to solve the spray of rubber products?

- The direct use of acid and alkali resistant wet toothbrush, spit spit yellow cream after treatment, scrub. Vomiting, vomiting and severe yellow,It can be repeated after drying. Oven, drying, packing, sealing, standby.

Send your message to us

Light Weight PVC PU Conveyor Belt Wood Application

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords