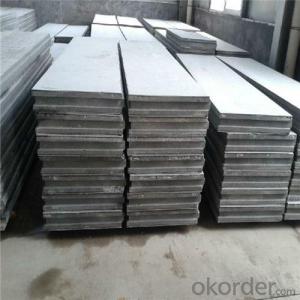

Light weight Fiber cement composite board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Performance Parameters: | |||||

| ltem | Unit | Thickness 125mm | Thickness 100mm | Thickness 75mm | Thickness 50mm |

| Standard of dry shrinkage value | mm/m | ≤0.6 | ≤0.52 | ≤0.49 | ≤0.46 |

| Sound insulation volume in the air | dB | ≥50 | ≥48 | ≥48 | ≥40 |

| Shockproof strength | The time of no through crack | 10 Times | 10 Times | 10 Times | 5 Times |

| Anti-bending collapsing strength | The multlple of the board's self-weight(Put pressure) | ≥6.0 | ≥6.0 | ≥6.0 | ≥6.0 |

| Hanging force | N | 1000 | 1000 | 1000 | 800 |

| Fire-resistant limit | H | 5 | 4 | 3 | 2 |

| Combustiblllty performance | Level | GB8624 A1 Level non-combustible | |||

| Coefficient of heat conductivily(W/MK) | 0.021 | ||||

| The Anti-returns(24h) | No drop of water and no damp | ||||

| Gas proof and anti-moth function | lnorganic substances have insect-resistant,gas proof and anti-moth performance | ||||

| Water permeability resistant | waterproof | ||||

| Moisture(%) | ≤9 | ||||

| Standard Specification: | |||||

| Width:610mm Length:3050/2440mm Thickness: 50/75/100/125mm | |||||

| Application Recommended: | |||||

| Widely used in non-load-bearing interior and exterior walls of buildings, commercial buildings, office partition wall,and need water proof, noise proof and moisture proof requirements place. | |||||

Fiber cemnt sandwich panel, light weight concrete sandwich panel

1. Composition:

Core materials: cement, EPS, and fly ash core

Surface materials: fiber reinforced calcium silicone board or cement calcium silicone board

2. Specification: (L*W*T)

1500-3000mm X 610mm X (50, 75, 100, 120,150,180mm)

fiber cement board on both sides: 5mm, 6mm, 8mm

3. Usage:

Interior and exterior partition on steel or concrete structure building,

For new construction, additions or renovations.

4. Advantages:

Energy-saving

Light weight

Sound insulation

Environmental protection

Most area-saving

Most waterproof and dampproff

Most fire-proof

Most sound-insulation

Best hanging force

Most anti-seismic and impact resistance

Largest span and height thin webbed wall

Most civilized, environmental, high efficiency construction.

- Q: Sandwich panel sandwich panel characteristics

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. Sandboard is a common product in the current building materials, not only can a very good flame retardant and environmentally friendly sandwich board English name: laminboard sandwich panel products are made of two layers of metal panels (or other material panels) and Directly in the middle of the panel foam, mature molding of the polymer core insulation composition. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. [1] The formation of the outer steel plate takes full account of the structural and strength requirements, and take into account the aesthetic, the inner layer of the formation of flat to meet the needs.

- Q: How do you keep the shower and the regulating valve on the foam sandwich plate? Please enlighten me

- It is best to do further reinforcement. But at the same time consider the beauty. If you can make this reinforcement done a little more, then put the control valve installed in the surface of the reinforcement is also possible.

- Q: Fuhan 18mmE0 grade sandwich panels how?

- Now are generally E1-class wood core board, and E1 grade Fuhan plate genuine goods, then environmental protection is the standard. E0 level of rare, and expensive

- Q: Rock wool color steel sandwich board rock wool bulk density

- 120 ~ 150kg / m ^ 3 Depending on the temperature difference, the temperature difference in the 130 ~ 180kg / m ^ 3 Attached to the industry standard

- Q: Aluminum magnesium manganese composite sandwich panel 90 degrees right angle how to fold

- Certainly the aluminum magnesium manganese plate light, the proportion of aluminum magnesium manganese plate is 4.71, the proportion of color steel plate is 7.85.

- Q: I would like to ask the color steel tile sandwich panels can cover the chicken coop? Does it have a good insulation effect?

- Can be, but the traditional ceiling color steel tile sandwich panels generally composite 10 cm thick white polystyrene foam insulation board, the insulation effect is not very good, this is because the thermal conductivity of polystyrene foam board is relatively high (thermal conductivity 0.035W / (m · K ) Above, plus foam and foam board between the gap, the temperature is very serious, comprehensive actual thermal conductivity is generally higher than 0.05. The new polyurethane spray insulation material can be directly sprayed on the color steel tile, the thermal conductivity is low, only 0.022-0.024W / (m · K), insulation effect is 2-3 times the polystyrene board, is the insulation of all insulation materials Especially excellent material. Because the polyurethane in the construction of the use of direct spray molding technology, so that the polyurethane foam layer without patchwork as a whole to form a complete impermeability, fundamentally put an end to the possibility of deep water along the seam along the seam. Which play a preservative and waterproof effect.

- Q: We want to build the activities of the board room is used as a dormitory, what materials used sandwich board good? What is the price of polystyrene board and rock wool board? As a dormitory board room in the height of the national standard? How high should it be?

- Mainly to see the use of activities, fire or rock wool sandwich board is good

- Q: I have a small shed, want to use sandwich panels construction, how can the summer 40 degrees with air conditioning to save power

- Wall plug a layer of sandwich panels no problem, but the window and sandwich panels to achieve the same insulation effect is difficult!

- Q: Do the closet with a sandwich board? Or with a MDF good?

- Or with sandwich panels, and now the market is a kind of better plate, called multi-layer solid wood or multi-layer plywood, the quality carry carry, and do the wardrobe is also very high Oh

- Q: What is the metal sandwich plate?

- Is the two sides are galvanized sheet, the middle folder things. Can give me a look at what the picture

Send your message to us

Light weight Fiber cement composite board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords