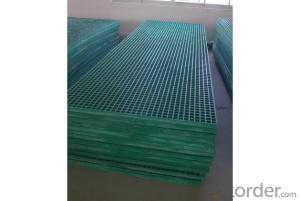

FRP Pultrusion Profiles - Lightweight and High Strength FRP Pultruded Grating and Pultrusion Process for Different Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenolic resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

PACKAGING & DELIVERY

1.Packaging Details:

plastic film and pallet

2.Delivery Detail:

In 5 days after receiving the down payment

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: Are FRP pultrusion profiles resistant to oils and greases?

- Yes, FRP pultrusion profiles are generally resistant to oils and greases. The combination of fiberglass reinforcement and resin matrix in FRP pultrusions provides excellent resistance to various chemicals, including oils and greases. This makes them suitable for applications where exposure to oils and greases is expected.

- Q: Will the FRP section crack for a long time?

- As long as the design of the structure is reasonable and the quality of the product conforms to the design requirements, the normal use shall not be cracked.

- Q: Can FRP pultrusion profiles be used in architectural or decorative applications?

- Yes, FRP pultrusion profiles can definitely be used in architectural or decorative applications. FRP, which stands for Fiber Reinforced Polymer, is a composite material that combines strong fibers, such as glass or carbon, with a polymer resin matrix. This combination creates a lightweight, durable, and corrosion-resistant material that is ideal for various applications, including architecture and decoration. FRP pultrusion profiles can be manufactured in a wide range of shapes and sizes, making them highly versatile for architectural and decorative purposes. These profiles can be used to create aesthetically pleasing structures, such as columns, beams, and facades, that enhance the visual appeal of buildings. Additionally, FRP pultrusion profiles can be fabricated to mimic the appearance of other materials, such as wood or metal, allowing for the creation of decorative elements that blend seamlessly with the overall design. Furthermore, FRP pultrusion profiles offer several advantages over traditional materials commonly used in architecture and decoration. They are lightweight, which makes them easier to handle and install, reducing labor costs. They are also highly resistant to corrosion, weathering, and UV radiation, ensuring long-lasting performance in outdoor applications. Additionally, FRP profiles can be customized to meet specific design requirements, including color, texture, and surface finish, providing endless possibilities for creative expression. In summary, FRP pultrusion profiles are a viable option for architectural and decorative applications. Their lightweight, durable, and customizable nature makes them suitable for a wide range of design needs, while their corrosion resistance ensures longevity and low maintenance. Whether it's for structural support or decorative embellishments, FRP pultrusion profiles offer an excellent choice for enhancing the aesthetics and functionality of architectural and decorative projects.

- Q: Are FRP pultrusion profiles resistant to electrical surges or lightning strikes?

- FRP pultrusion profiles have inherent electrical insulation properties due to their composition of fiberglass reinforcement and resin matrix. This insulation makes them resistant to electrical surges and lightning strikes to some extent. However, it is important to note that no material can provide absolute protection against extremely high voltage electrical surges or direct lightning strikes. In such cases, additional measures like grounding and lightning protection systems are necessary to ensure the safety of structures or equipment. Therefore, while FRP pultrusion profiles offer some level of resistance to electrical surges and lightning strikes, it is advisable to consult with experts and adhere to relevant safety standards when designing and installing electrical systems in areas prone to such events.

- Q: Can FRP pultrusion profiles be used in electrical insulation applications?

- Yes, FRP pultrusion profiles can be used in electrical insulation applications. FRP (Fiber Reinforced Polymer) materials have excellent electrical insulation properties, making them suitable for a wide range of electrical applications. The pultrusion process ensures that the profiles have uniform insulation properties and high strength, making them ideal for use in electrical insulation applications.

- Q: Are FRP pultrusion profiles resistant to termites?

- FRP pultrusion profiles are typically immune to termites. Termites mainly consume materials that contain cellulose, such as wood. However, FRP pultrusion profiles, composed of resin and glass fibers, lack cellulose and are hence unappealing to termites. As a result, FRP pultrusion profiles offer an excellent substitute for conventional wooden profiles in situations that demand termite resistance, like building construction and outdoor structures. Furthermore, FRP profiles demonstrate resistance against decay, corrosion, and various environmental elements, rendering them a robust and enduring material option.

- Q: Are FRP pultrusion profiles resistant to electromagnetic interference?

- FRP pultrusion profiles are known for their resistance to electromagnetic interference (EMI). By using fiberglass reinforced plastic (FRP) in pultrusion profiles, they offer exceptional electrical insulation properties that effectively minimize the impact of electromagnetic interference. Unlike conductive metals, FRP materials possess high dielectric strength and low electrical conductivity. As a result, FRP pultrusion profiles are less vulnerable to EMI and can serve as barriers against electromagnetic waves. Moreover, if necessary, additional layers or coatings can be applied to enhance the EMI shielding effectiveness of FRP materials. In conclusion, for applications where resistance to electromagnetic interference is crucial, FRP pultrusion profiles are a dependable choice.

- Q: How do FRP pultrusion profiles handle bending and flexing?

- FRP pultrusion profiles are designed to handle bending and flexing exceptionally well due to their inherent structural properties. The combination of reinforcing fibers, such as fiberglass, and a polymer resin matrix in the pultruded profiles results in high strength and stiffness. This allows the profiles to withstand bending forces without any significant deformation or failure. Additionally, the ability of FRP to withstand flexing is attributed to its high fatigue resistance, making it suitable for applications that require repeated bending or flexing movements.

- Q: Can FRP pultrusion profiles be used in electrical insulation applications?

- FRP pultrusion profiles are capable of being utilized in electrical insulation applications. They possess exceptional electrical insulation properties, rendering them appropriate for a broad range of electrical applications. The superior dielectric strength of FRP materials ensures the efficient containment of electrical currents within designated pathways, thus preventing leakage and electrical hazards. Moreover, FRP profiles exhibit low electrical conductivity, thereby decreasing the likelihood of electrical shorts and enhancing overall safety in electrical insulation applications. The non-magnetic characteristics of FRP materials are also advantageous as they eliminate the potential for electromagnetic interference (EMI) in sensitive electrical systems. Furthermore, FRP pultrusion profiles are lightweight, resistant to corrosion, and boast a lengthy operational lifespan. This renders them an economical and robust solution for electrical insulation applications.

- Q: Can FRP pultrusion profiles be used in the construction of water slides?

- Yes, FRP pultrusion profiles can be used in the construction of water slides. FRP, or fiberglass reinforced plastic, offers excellent strength, durability, and corrosion resistance, making it a suitable material for water slide components. The pultrusion process allows for the production of customized profiles with specific shapes and dimensions, ensuring compatibility with water slide design requirements. Additionally, FRP's lightweight nature simplifies installation and maintenance while providing a safe and enjoyable experience for water slide users.

Send your message to us

FRP Pultrusion Profiles - Lightweight and High Strength FRP Pultruded Grating and Pultrusion Process for Different Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords