FRP Pultrusion Profiles - Lightweight FRP Pultruded Grating and Pultrusion Process for Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

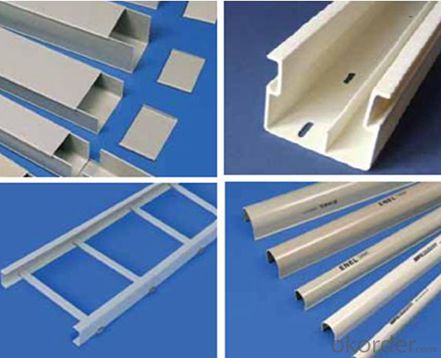

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenolic resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: Are FRP pultrusion profiles resistant to hydrocarbons?

- FRP pultrusion profiles are known to be resistant against hydrocarbons. By combining different reinforcing fibers, such as fiberglass or carbon fiber, with a polymer matrix, FRP materials exhibit a high level of resistance to chemical corrosion, including hydrocarbons. This resistance makes FRP pultrusion profiles an excellent choice for applications that involve exposure to hydrocarbons, such as in the oil and gas industry, chemical processing plants, and fuel storage facilities. However, it is important to bear in mind that the level of resistance may vary depending on the specific resin used in the FRP material, as well as the concentration and temperature of the hydrocarbons present. Hence, it is advisable to consult with the manufacturer or supplier of the FRP pultrusion profiles to confirm their compatibility with the particular hydrocarbon environment at hand.

- Q: Can FRP pultrusion profiles be used in agricultural structures?

- Yes, FRP pultrusion profiles can certainly be used in agricultural structures. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications in the agricultural industry. These profiles can be used in structures like greenhouse frames, livestock enclosures, support beams, fencing, and other agricultural infrastructure.

- Q: Are FRP pultrusion profiles resistant to biological growth, such as mold or mildew?

- FRP pultrusion profiles are highly resistant to biological growth, such as mold and mildew. These profiles have a non-porous structure that makes it difficult for microorganisms to attach and grow. They are typically made with a combination of resin and glass fibers, both of which naturally resist biological growth. In contrast to materials like wood or metal, FRP does not create an ideal environment for mold or mildew. The smooth and non-porous surface of FRP prevents moisture absorption, which is necessary for microorganisms to thrive. Additionally, FRP materials lack organic compounds that can support the growth of mold or mildew, thus enhancing their resistance to biological degradation. When it comes to applications that require resistance to biological growth, FRP pultrusion profiles offer a significant advantage over other materials. They are commonly used in environments with high humidity, moisture, or water exposure, such as marine, agricultural, or wastewater treatment facilities. Furthermore, FRP profiles are frequently employed indoors in areas where mold or mildew growth is a concern, such as sanitary areas or food processing plants. Overall, FRP pultrusion profiles are an excellent solution for combating biological growth, including mold and mildew. Their non-porous nature, combined with the inherent resistance of the materials used in their manufacturing, ensures durability and longevity in environments where microbial growth is a potential issue.

- Q: Can FRP pultrusion profiles be used in the construction of water treatment plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of water treatment plants. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them well-suited for water treatment plant applications. These profiles can be used in various structural components like beams, columns, grating, and handrails, providing a cost-effective and long-lasting solution for the construction of water treatment plants.

- Q: Are FRP pultrusion profiles resistant to termites or other pests?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are inherently resistant to termites and other pests. Unlike traditional wood or metal materials, FRP profiles do not provide a food source for termites or any other pests. FRP is composed of a combination of reinforced fibers and a polymer matrix, typically made of fiberglass and resin. These materials are not appealing to pests and do not provide any nutritional value, making FRP profiles highly resistant to termite damage or infestation. This resistance to pests is one of the many advantages of using FRP pultrusion profiles in various applications, especially in outdoor or humid environments where termites are commonly found.

- Q: Are FRP pultrusion profiles resistant to caustic soda?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are typically resistant to caustic soda. Caustic soda, also known as sodium hydroxide, is a strong alkaline substance that can corrode certain materials. However, FRP pultrusion profiles are made of a combination of strong fibers (such as fiberglass) and a resin matrix (such as polyester or epoxy). This composite construction provides excellent resistance to chemicals, including caustic soda. FRP pultrusion profiles are often used in industries where exposure to corrosive substances is common, such as chemical processing, wastewater treatment, and mining. It is important to note that the specific resin used in the FRP profiles and the concentration and temperature of the caustic soda may affect the overall resistance.

- Q: Are FRP pultrusion profiles electrically conductive?

- Typically, FRP pultrusion profiles lack electrical conductivity due to the utilization of a blend of fiberglass reinforcement and a thermosetting resin matrix. These components offer exceptional insulation qualities. The inherent non-conductive nature of the fiberglass reinforcement is further amplified by the resin matrix. Consequently, FRP pultrusion profiles find frequent application in situations where electrical conductivity is undesirable or poses safety hazards. Nevertheless, it is noteworthy that specific modifications or additions can be implemented during the pultrusion process to introduce electrical conductivity, if needed for particular applications.

- Q: Are FRP pultrusion profiles resistant to chemicals used in chemical plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to the chemicals typically used in chemical plants. The combination of reinforced fibers and a polymer matrix in FRP profiles provides excellent resistance to a wide range of corrosive substances, making them an ideal choice for chemical plant applications.

- Q: Can FRP pultrusion profiles be used in aerospace applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in aerospace applications. These profiles offer a combination of strength, lightweight, and corrosion resistance, making them suitable for various aerospace components such as structural supports, fairings, and interior panels. Additionally, FRP pultrusion profiles have high fatigue resistance and can withstand extreme temperatures, enhancing their suitability for aerospace use.

- Q: Are FRP pultrusion profiles resistant to moisture?

- Yes, FRP pultrusion profiles are highly resistant to moisture due to the inherent properties of fiberglass and the resin matrix used in their production. This resistance makes them an excellent choice for applications where moisture exposure is a concern, such as outdoor structures, marine environments, and infrastructure exposed to wet conditions.

Send your message to us

FRP Pultrusion Profiles - Lightweight FRP Pultruded Grating and Pultrusion Process for Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords