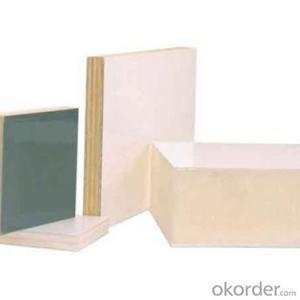

FRP Pultrusion Profiles - Lightweight and High Strength FRP Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

PACKAGING & DELIVERY

1.PACKAGING DETAILS:

standard packing or your requirement

2.DELIVERY DETAIL:

Shipped in 30 days after payment

- Q: Are FRP pultrusion profiles resistant to seismic activity?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength-to-weight ratio and excellent mechanical properties. However, when it comes to seismic activity, their resistance depends on various factors. In general, FRP pultrusion profiles can exhibit good resistance to seismic activity due to their inherent properties. The composite materials used in their construction, such as fiberglass and resin, offer high tensile strength and stiffness, making them capable of withstanding dynamic loads caused by earthquakes. Moreover, FRP pultrusion profiles have been extensively tested and proven to possess excellent fatigue resistance. This property is crucial during seismic events as structures are subjected to repeated dynamic loading. The ability of FRP profiles to withstand cyclic loading without suffering from fatigue failure significantly enhances their seismic resistance compared to traditional materials like steel or concrete. Another advantage of FRP pultrusion profiles in seismic activity is their lightweight nature. Their low weight reduces the overall mass of the structure, resulting in lower seismic forces. This weight reduction can lead to reduced seismic responses and less damage during an earthquake. However, it is important to note that the seismic resistance of FRP pultrusion profiles can be influenced by various factors. These include the design and quality of the profiles, the connection details, and the overall structural system in which they are used. Proper engineering and design considerations must be taken into account to ensure optimal performance and seismic resistance. In conclusion, FRP pultrusion profiles have the potential to offer good resistance to seismic activity due to their high strength, stiffness, and fatigue resistance. However, their performance in seismic events depends on various factors, and careful design and engineering practices are essential to maximize their seismic resistance.

- Q: Can FRP pultrusion profiles be used in aerospace applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in aerospace applications. These profiles offer a combination of strength, lightweight, and corrosion resistance, making them suitable for various aerospace components such as structural supports, fairings, and interior panels. Additionally, FRP pultrusion profiles have high fatigue resistance and can withstand extreme temperatures, enhancing their suitability for aerospace use.

- Q: Can FRP pultrusion profiles be used in the production of electrical cabinets?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can definitely be used in the production of electrical cabinets. FRP pultrusion profiles have excellent electrical insulating properties, making them a suitable choice for applications involving the production of electrical cabinets. These profiles are non-conductive and can provide insulation and protection against electrical currents, ensuring the safety of the electrical components housed within the cabinet. Additionally, FRP pultrusion profiles offer high strength-to-weight ratio, corrosion resistance, and durability, making them a reliable choice for long-lasting electrical cabinets in various environments.

- Q: Are FRP pultrusion profiles fire resistant?

- Yes, FRP pultrusion profiles are fire resistant.

- Q: Can FRP pultrusion profiles be used in railway applications?

- FRP pultrusion profiles are applicable in railway industries due to their high strength-to-weight ratio, durability, and resistance to corrosion. They can be utilized for various railway components such as sleepers, bridges, platforms, cable management systems, and structural support for tracks. These profiles possess exceptional mechanical properties, including high stiffness and tensile strength, which are crucial for maintaining the safety and integrity of railway infrastructure. Moreover, FRP pultrusion profiles exhibit low thermal conductivity, making them resistant to extreme temperature fluctuations commonly encountered in railway applications. Another significant advantage of employing FRP pultrusion profiles in railway settings is their resistance to corrosion. Unlike steel, FRP does not rust or corrode when exposed to moisture or chemicals. Consequently, the need for regular maintenance is reduced, thus extending the lifespan of railway components and reducing costs in the long term. Furthermore, FRP pultrusion profiles can be easily tailored to meet specific design requirements. They can be manufactured in various shapes, sizes, and colors, allowing engineers to create customized solutions for diverse railway applications. In summary, the use of FRP pultrusion profiles in railway industries offers numerous benefits, including lightweight design, high strength, corrosion resistance, and customization options. These qualities make FRP an appealing alternative to traditional materials, thereby enhancing the safety, efficiency, and longevity of railway infrastructure.

- Q: Can FRP pultrusion profiles be used in telecommunications towers?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in telecommunications towers. FRP pultrusion profiles offer several advantages that make them suitable for this application. Firstly, FRP profiles are lightweight yet strong, allowing for easy installation and reduced structural weight in telecommunications towers. This is important as it helps to minimize the overall weight load on the tower structure. Secondly, FRP pultrusion profiles have excellent corrosion resistance properties, making them ideal for outdoor applications like telecommunications towers, which are exposed to various environmental conditions. Unlike traditional materials such as steel or wood, FRP profiles do not rust, rot, or degrade when exposed to moisture, UV radiation, or chemicals typically found in outdoor environments. Additionally, FRP pultrusion profiles offer excellent electrical insulation properties, which is crucial in telecommunications towers. These profiles do not conduct electricity, reducing the risk of electrical interference or short circuits that could disrupt the tower's communication systems. Furthermore, FRP pultrusion profiles can be manufactured in various shapes and sizes, allowing for customization and meeting specific design requirements of telecommunications towers. This versatility allows for better integration and compatibility with other tower components. Overall, the combination of lightweight, high strength, corrosion resistance, electrical insulation, and customization options make FRP pultrusion profiles a viable and advantageous choice for use in telecommunications towers.

- Q: Can FRP pultrusion profiles be used in the construction of industrial flooring?

- Indeed, the utilization of FRP (Fiber Reinforced Polymer) pultrusion profiles is viable in the construction of industrial flooring. These profiles are comprised of a composite material, combining robust fibers (usually glass or carbon) with a polymer resin. This amalgamation of materials imparts exceptional strength, durability, and resistance to corrosion, rendering FRP profiles highly suitable for industrial flooring applications. The primary benefit of FRP pultrusion profiles lies in their remarkable strength-to-weight ratio. Consequently, they are lighter and more manageable compared to conventional materials like steel or concrete. Moreover, FRP profiles possess non-conductive and non-magnetic properties, offering advantages in specific industrial environments. FRP pultrusion profiles also exhibit high resistance to various chemicals, moisture, and UV radiation, making them an ideal choice for harsh and corrosive settings. Unlike steel, they do not rust or corrode, nor are they affected by moisture or rot like wood. As a result, they ensure long-lasting performance and necessitate minimal maintenance. Additionally, FRP profiles can be customized and manufactured in diverse shapes, sizes, and load-bearing capacities to meet specific industrial flooring requirements. They can be designed to withstand heavy loads, impact, vibration, and other dynamic forces commonly encountered in industrial settings. In conclusion, FRP pultrusion profiles offer numerous advantages that make them well-suited for the construction of industrial flooring. Their high strength, durability, corrosion resistance, and customizable nature make them a dependable and cost-effective choice for industrial flooring applications.

- Q: Are FRP pultrusion profiles resistant to nitric acid?

- FRP pultrusion profiles exhibit a general resistance to nitric acid. Nitric acid, being a potent oxidizing agent, has the ability to corrode various materials, including metals. However, the construction of FRP pultrusion profiles involves the use of composite materials that are specifically engineered to withstand the effects of corrosive substances, including nitric acid. The resilience of FRP pultrusion profiles against corrosion is attributed to the combination of reinforcing fibers, such as fiberglass or carbon fiber, and a resin matrix that securely binds these fibers together. The resin matrix, typically a thermosetting polymer like polyester or epoxy, forms a protective barrier that shields the profiles from corrosive substances. Nitric acid is renowned for its capacity to corrode and deteriorate metals. Nonetheless, FRP pultrusion profiles exhibit exceptional resistance to nitric acid due to the inert nature of the composite materials employed. The reinforcing fibers utilized in FRP profiles do not react with nitric acid, while the resin matrix effectively prevents the acid from reaching and corroding the fibers by acting as a barrier. It is essential to acknowledge that the specific resistance of FRP pultrusion profiles to nitric acid may vary depending on the precise composition of the composite materials utilized, as well as the concentration and temperature of the nitric acid. Therefore, it is always advisable to consult the manufacturer or supplier of FRP profiles to ensure their compatibility with nitric acid in specific applications.

- Q: Can FRP pultrusion profiles be used in the construction industry?

- Indeed, the construction industry can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles offer numerous benefits that make them appropriate for diverse construction applications. To begin with, FRP pultrusion profiles possess exceptional strength while remaining lightweight. Consequently, they are an excellent choice for construction projects as they provide a high strength-to-weight ratio. This reduces the overall weight of the structure while preserving its structural integrity. This advantage is particularly valuable for applications like bridges, walkways, and platforms. Furthermore, FRP pultrusion profiles exhibit a high level of resistance to corrosion. Unlike conventional construction materials such as steel or wood, FRP does not rust, rot, or corrode when exposed to harsh environmental conditions, chemicals, or moisture. Consequently, FRP profiles are ideal for outdoor or marine applications where corrosion can be a concern, such as seawalls, docks, or offshore structures. In addition, FRP pultrusion profiles possess excellent electrical and thermal insulation properties. This makes them suitable for applications where minimizing electrical conductivity is necessary, such as electrical enclosures or cable trays. Moreover, FRP profiles have low thermal conductivity, which enhances energy efficiency in buildings by reducing heat transfer. Furthermore, FRP pultrusion profiles are highly durable and require minimal maintenance. They boast a long service life and do not necessitate regular painting, sealing, or treatment like traditional materials. Consequently, significant cost savings can be achieved throughout the life cycle of a construction project. Lastly, FRP pultrusion profiles can be customized to meet specific strength, stiffness, and dimensional requirements. They can be produced in various shapes, sizes, and colors, allowing for flexibility in design. This versatility renders FRP profiles suitable for a wide range of construction applications, including beams, columns, gratings, handrails, and structural components. To summarize, FRP pultrusion profiles are a viable choice for the construction industry due to their lightweight nature, high strength, corrosion resistance, electrical and thermal insulation properties, durability, low maintenance requirements, and design flexibility.

- Q: Are FRP pultrusion profiles resistant to fuels?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fuels. The combination of high-strength fibers and a polymer matrix makes FRP profiles highly resistant to various chemicals, including fuels. This resistance is primarily due to the non-reactive nature of the polymer matrix, which prevents the fuel from causing any significant degradation or damage to the profiles. FRP pultrusion profiles are commonly used in industries where exposure to fuels is a common occurrence, such as the automotive, aerospace, and oil and gas sectors. These profiles have been extensively tested and proven to withstand prolonged contact with fuels without experiencing any detrimental effects. Additionally, FRP profiles offer several advantages over traditional materials like steel or aluminum in fuel-related applications. They are corrosion-resistant, lightweight, and have excellent dimensional stability, making them ideal for use in environments where the risk of fuel exposure is high. However, it is important to note that the specific resistance of FRP pultrusion profiles to fuels may vary depending on the type and concentration of the fuel, as well as the specific composition of the FRP material. Therefore, it is always recommended to consult with the manufacturer or supplier to ensure that the chosen FRP profiles are suitable for the specific fuel-related application.

Send your message to us

FRP Pultrusion Profiles - Lightweight and High Strength FRP Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords