Lennox Aluminum Coils - PE Coated Embossed Aluminium Coil AA8011

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

PE Coated Embossed aluminium coils are widly used in decoration field, especially in Africa. For the period, it depends on the using evironment. If you use in the open air, it can remain 5-10 years.. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

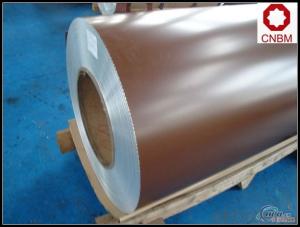

3. Image

4.Products Specification

| Alloy | Temper | Thickness | Coil Weight | Coil ID |

| AA8011 | H18 | 0.2-0.5MM | 2 tons | 508mm+/-10mm |

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: May anyone tell me what's the product when hydrochloric acid reacts with aluminum?HCl + Al → ?

- Amonia Hydrochlorite

- Q: Can aluminum coils be used for signage and display applications?

- Yes, aluminum coils can be used for signage and display applications. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion, making it an ideal choice for various signage and display purposes. Its flexibility allows for easy shaping and customization, while its smooth surface provides a perfect canvas for printing graphics and designs. Additionally, aluminum coils can be easily mounted, making them suitable for both indoor and outdoor signage and displays.

- Q: Are there any limitations to the coil weight of aluminum coils?

- The coil weight of aluminum coils is subject to limitations. The primary factor that restricts the coil weight is the capacity of the equipment used for handling and transporting the coils. Different machinery and materials handling systems have varying weight capacities. Exceeding these capacities can result in safety hazards and equipment damage. Furthermore, the size and dimensions of the coils also affect the maximum weight limit. Larger coils generally have a higher weight limit because they possess a larger surface area to distribute the load. Nonetheless, regardless of coil size, there is a practical limit to the weight that the machinery and equipment can bear. Additionally, the coil weight limit is influenced by the strength and integrity of the material used. Aluminum, being a lightweight material with a high strength-to-weight ratio, allows for larger coil weights compared to other materials. However, excessive weight may cause deformation or damage to the coil, impacting its quality and usability. It is essential to take these limitations into consideration and adhere to the manufacturer's recommendations and industry standards when determining the maximum coil weight. Following proper handling, storage, and transportation procedures is crucial to ensure the safety of personnel and the integrity of the aluminum coils.

- Q: I have been trying to make some thermite for a while now, and I haven't had much success. I have tried using iron oxide and that didn't work. then I tried using manganese dioxide, also without success. I'm pretty sure I have the right proportions for each of the corresponding oxides, but it just isn't working. I am using magnesium ribbon to light it.The aluminum I am using is the byproduct of me trying to cut a block of aluminum with a hacksaw (best way I have available to cut it) and there is a lot of aluminum powder that is being made. But i'm not sure if it is fine enough to be effective. I don't have an etch-a -sketch so that's not an option. I know that it has to be fairly fine grained, but how small do the particles need to be?FOR EVERYONE WHO IS GOING TO TRY AND TELL ME THAT MAKING THERMITE IS DANGEROUS OR SOMETHING ALONG THOSE LINES......DONT!!!!!!!!.......... IM NOT GOING TO LISTEN SO SAVE YOURSELF THE TYPING AND ME THE READING

- In 35+ years of demonstrating the thermite reaction, I have used fine aluminium powder to quite visible small bits. The proportions don't seem too critical, but try and keep near the amounts represented by the balanced eqtn. The difficult bit is getting the wretched stuff to ignite. With some mixes several strands of magnesium ribbon as fuse still wouldn't get it to ignite. I found a pile of 'ignition powder' at the base of the Mg often helped. There was a good commercial one available in the UK but I often made one up, main ingredients barium peroxide and magnesium powder, about 50/50. Needless to say, ignite with this mix where you won't breathe any nasty fumes. To get a good result, if I didn't use a proper crucible, I shaped one of Al foil about the capacity of 2-3 eggcups. This was put on sand in a big coffee tin, then more sand added to fill round the sides. This would give a good amount of iron. I once made the mistake of rushing in too quickly to get out the red hot iron.... and completely melted the ends of a large pair of Nickel tongs!

- Q: Can aluminum coils be used for seamless gutters?

- Seamless gutters can indeed utilize aluminum coils. The reason aluminum is favored for gutter systems is its ability to withstand wear, its lightweight composition, and its resistance to rust. Aluminum coils are frequently employed in the construction of seamless gutters, which boast several advantages over the more traditional sectional gutters. Custom-made on-site, seamless gutters guarantee a flawless fit for the specific measurements of a structure. This eliminates the necessity for seams, which are susceptible to leaks and require regular maintenance. Moreover, aluminum is malleable, making it easy to shape seamless gutters to accommodate a building's unique design. In summary, aluminum coils present a practical and efficient option for the creation of seamless gutters.

- Q: Can aluminum coils withstand high temperatures?

- High temperatures are easily withstood by aluminum coils. With a melting point of around 660 degrees Celsius (1220 degrees Fahrenheit), aluminum possesses a relatively high melting point. Consequently, it becomes a suitable choice for applications in high-temperature environments. Moreover, the exceptional thermal conductivity of aluminum facilitates efficient heat dissipation. Due to this characteristic, aluminum coils frequently find application in heat exchangers and diverse heating applications. Nevertheless, it is crucial to acknowledge that the temperature limit for aluminum coils may differ depending on the specific alloy and application.

- Q: What are the strength properties of aluminum coils?

- Aluminum coils possess several strength properties that make them highly desirable in various applications. Firstly, aluminum has a high strength-to-weight ratio, which means that it is lightweight while still maintaining good strength. This makes aluminum coils ideal for industries where weight reduction is important, such as in the automotive and aerospace sectors. Additionally, aluminum coils offer excellent corrosion resistance, even when exposed to harsh environments. This corrosion resistance is due to the formation of a protective oxide layer on the surface of the aluminum, which helps to prevent further degradation. Moreover, aluminum coils display good formability and ductility, allowing them to be easily shaped and formed into different products without compromising their structural integrity. This makes them suitable for various manufacturing processes, including rolling, bending, and stamping. Furthermore, aluminum coils possess good electrical and thermal conductivity, making them ideal for applications requiring efficient heat transfer or electrical conductivity, such as in heat exchangers or electrical wiring. In summary, the strength properties of aluminum coils include high strength-to-weight ratio, excellent corrosion resistance, good formability, and ductility, as well as efficient electrical and thermal conductivity. These characteristics contribute to the versatility and widespread use of aluminum coils in numerous industries.

- Q: Can aluminum coils be used in the manufacturing of cans and containers?

- Yes, aluminum coils are commonly used in the manufacturing of cans and containers. Aluminum is lightweight, durable, and resistant to corrosion, making it an ideal material for packaging food and beverages. The coils are typically processed and shaped into desired can or container forms before being used in the manufacturing process.

- Q: What are the standard sizes of aluminum coils?

- The standard sizes of aluminum coils vary depending on the manufacturer and application, but common sizes range from 0.008 inches to 0.25 inches in thickness and 12 inches to 60 inches in width.

- Q: How do you store and transport aluminum coils?

- Aluminum coils are typically stored and transported using a few different methods to ensure their safety and prevent damage. When it comes to storage, it is essential to keep the coils in a dry, clean, and well-ventilated area to avoid any moisture-related issues or corrosion. Ideally, the storage area should have a controlled temperature to prevent any extreme fluctuations that could affect the quality of the aluminum. To protect the coils from physical damage, they should be stored horizontally or vertically on a stable and level surface. It is crucial to avoid stacking them too high to prevent any potential collapse and ensure easy access for inspection or transportation purposes. Additionally, placing them on wooden pallets or racks with proper spacing between each coil can provide extra stability and protection. When it comes to transporting aluminum coils, there are several options available depending on the quantity, distance, and mode of transportation. For short distances or smaller quantities, hand trucks or forklifts can be used to move the coils onto a flatbed truck or a van. It is important to secure the coils properly using straps or bands to prevent any movement during transit. For larger quantities or longer distances, the coils can be transported using specialized coil carriers. These carriers are designed to securely hold multiple coils in an organized manner, limiting any potential damage caused by vibration or shifting during transportation. They are typically equipped with side rails and restraining bars to secure the coils in place. Regardless of the method used for transportation, it is crucial to handle the aluminum coils with care and ensure they are adequately protected. Regular inspections should be conducted before, during, and after transportation to identify any signs of damage or issues that could compromise the integrity of the coils. By following these guidelines, the storage and transportation of aluminum coils can be done efficiently and safely.

Send your message to us

Lennox Aluminum Coils - PE Coated Embossed Aluminium Coil AA8011

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords