Led Strip Channels Aluminum Profiles for Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

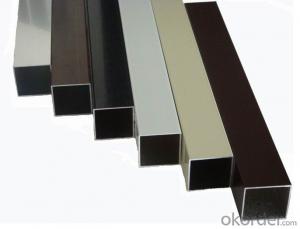

Aluminum profile

1. Brand: Bright Star

2. Place of origin: Guangdong, China

3. Temper: T5/T6

4. Grade: 6000 S

Goldsword Aluminum Factory | |

Business Type | Aluminum profile Manufacturer |

Product series | aluminum profile for window and doors |

Price Determination | Based on Aluminum Ingot Price + Process fee |

Payment Term | T/T, L/C at sight |

Surface Treatment | We can provide aluminum profiles with mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Color | We can provide white, wood color, black, golden, blue, champagne, and other colors as required. |

Packing | Composite paper, Plastic paper, other packing method required by customers is available. 2 to 20 pcs per bundle, sometimes small profiles are plugged in big ones so as to save space for customers. |

Product specification | 1. Alloy: 6063-T5/T6 2. Length: 3-6.5 m 3. Normal anodizing thickness: 8 to 12 micro 4. Normal powder coating thickness: 60 – 100 micro 5. Tensile Strength: ≥160 MPa 6. Yield strength: ≥110 MPa 7. Extensibility: ≥8% 8. Hardness (HW): ≥8 |

- Q: This question asks for the various types of aluminum profiles that are utilized in roofing systems.

- <p>Aluminum profiles for roofing systems come in various types, each serving specific purposes. Common types include: 1. <strong>Gutter Profiles</strong>: Used for collecting and directing rainwater from the roof. 2. <strong>Fascia Profiles</strong>: Cover the ends of rafters and provide a finished edge to the roof. 3. <strong>Soffit Profiles</strong>: Installed under the eaves to allow ventilation and conceal the underside of the roof. 4. <strong>Purlin Profiles</strong>: Support the roof sheeting and are placed perpendicular to the rafters. 5. <strong>Rafter Profiles</strong>: Mimic traditional wooden rafters and provide structural support. 6. <strong>Roof Ridge Profiles</strong>: Cap the ridge of the roof, where two slopes meet. 7. <strong>Hip and Valley Profiles</strong>: Used at the intersection of two sloping roof surfaces. Each profile is designed to withstand weather conditions and provide durability, with specific dimensions and shapes tailored to the roofing system's requirements.</p>

- Q: Is it possible to use aluminum profiles as a material for exterior walls or facades?

- <p>Yes, aluminum profiles can be used for exterior cladding or siding. They are known for their durability, low maintenance, and resistance to weather and corrosion, making them ideal for exterior applications. Aluminum profiles are lightweight, easy to install, and can be painted or finished in various ways to match architectural designs. They also offer excellent thermal performance and can be recycled, contributing to sustainability.</p>

- Q: Differences between industrial aluminum and iron products

- Aluminum profiles are widely used, especially in industrial manufacturing.Iron products of high hardness, high temperature resistance, good processing performance, than the major, Nailanai shear stress; industrial aluminum and aluminum is of low hardness, good ductility, good corrosion resistance, light weight, good conductivity.

- Q: How do you prevent galvanic corrosion when combining aluminum profiles with other metals?

- To avoid galvanic corrosion when combining aluminum profiles with other metals, there exist several effective measures that can be implemented: 1. Opt for compatible metals: Choose metals that are closely ranked in the galvanic series to minimize the potential difference between them. This decreases the likelihood of galvanic corrosion. For instance, utilizing stainless steel or titanium alongside aluminum can be a wise decision. 2. Insulate the metals: Employ insulating materials, like non-conductive coatings, paints, or tapes, to establish a barrier between the aluminum and other metals. This prevents direct contact and hinders galvanic corrosion. 3. Employ protective coatings: Administer protective coatings, such as anodizing or powder coating, to the aluminum surface. These coatings serve as a protective layer, preventing direct contact between the aluminum and other metals, thereby reducing the risk of galvanic corrosion. 4. Utilize isolating washers or gaskets: When fastening aluminum profiles to other metals, employ isolating washers or gaskets composed of non-conductive materials like rubber or plastic. These washers or gaskets create a barrier between the metals, thus preventing galvanic corrosion. 5. Consider design: Construct the structure in a manner that minimizes the potential for water or moisture accumulation between dissimilar metals. Adequate drainage and ventilation can help decrease the chances of galvanic corrosion. 6. Regularly maintain and inspect: Carry out routine inspections to promptly identify any signs of galvanic corrosion. If corrosion is detected, take appropriate action to rectify the situation, such as replacing damaged components or applying protective coatings. By adhering to these preventive measures, the risk of galvanic corrosion can be significantly diminished, ensuring the longevity and performance of the combined aluminum profiles and other metals.

- Q: Can aluminum profiles be utilized in high-rise constructions that incorporate large windows?

- <p>Yes, aluminum profiles are commonly used in high-rise buildings with large windows due to their strength, durability, and lightweight properties. They offer excellent resistance to corrosion and weathering, making them ideal for external applications. Additionally, aluminum profiles can be easily customized to fit various window designs and sizes, providing both aesthetic and functional benefits. Their thermal break technology also helps in reducing heat transfer, enhancing energy efficiency in buildings.</p>

- Q: This question asks for guidance on selecting the appropriate aluminum profile for a construction project.

- <p>To choose a suitable aluminum profile for your building project, consider the following: First, assess the structural requirements such as load-bearing capacity and span. Second, consider the aesthetic preferences and the desired finish or color. Third, evaluate the environmental conditions the profile will be exposed to, such as weather resistance and corrosion. Fourth, consult with suppliers or manufacturers for technical specifications and recommendations. Fifth, ensure compliance with building codes and standards. Finally, factor in the cost and availability of the profiles. It's often helpful to consult with engineers or architects who can provide expert advice tailored to your specific project needs.</p>

- Q: Can aluminum be utilized as a material for constructing railings and fences?

- <p>Yes, aluminum profiles are commonly used for railings and fences due to their durability, low maintenance, and resistance to corrosion. They are lightweight, easy to install, and can be powder-coated in various colors to match architectural styles. Aluminum railings and fences are also appreciated for their strength and ability to withstand harsh weather conditions without rusting or rotting, making them a popular choice for both residential and commercial applications.</p>

- Q: How do aluminum profiles compare to other types of materials?

- Compared to other materials, aluminum profiles possess several advantages. Firstly, their lightweight nature is well-known, making them easier to handle and transport. This quality is particularly advantageous in industries where weight reduction is crucial, such as aerospace and automotive sectors. Secondly, aluminum profiles exhibit excellent resistance to corrosion. Unlike materials like steel or iron, aluminum does not rust when exposed to moisture or other corrosive elements. This makes aluminum profiles ideal for outdoor applications or in environments where moisture is present, such as marine or coastal areas. Furthermore, aluminum profiles have a high strength-to-weight ratio, meaning they are relatively strong while remaining lightweight. This attribute allows for the utilization of aluminum in various structural applications, where strength is important but weight reduction is also desired. Moreover, aluminum profiles are highly versatile and can be easily extruded into different shapes and sizes to meet specific design requirements. This flexibility permits customization and adaptability in various industries, including construction, transportation, and industrial manufacturing. Lastly, aluminum is an incredibly sustainable material. It is 100% recyclable, meaning it can be melted down and reused without any loss in quality. This contributes to the reduction of environmental impact and promotes a circular economy. In conclusion, aluminum profiles offer a combination of lightweight properties, corrosion resistance, strength, versatility, and sustainability, making them a favorable choice over other materials in numerous applications.

- Q: Can aluminum profiles be used in the construction of greenhouses?

- Indeed, the utilization of aluminum profiles in the creation of greenhouses is possible. Due to its lightweight and enduring attributes, aluminum emerges as a commendable selection for constructing these structures. It possesses corrosion resistance, a crucial characteristic in the moisture-laden and damp atmosphere of greenhouses. The ease with which aluminum profiles can be fabricated and assembled lends itself to the flexibility of design and construction. Moreover, aluminum qualifies as an environmentally sustainable material, given its 100% recyclability, rendering it an eco-friendly choice for greenhouse construction. All in all, the practicality and dependability of aluminum profiles make them a viable option for erecting greenhouses.

- Q: This question asks about the various types of aluminum profiles that are specifically used for the purpose of insulating exterior walls.

- <p>Aluminum profiles for exterior wall insulation are crucial for thermal efficiency and structural integrity. Common types include: 1. <strong>Aluminum Cladding Profiles</strong>: These cover the insulation and provide a weather-resistant barrier. 2. <strong>Aluminum Insulation Fin Profiles</strong>: Used to create a gap for insulation material between the wall and the cladding. 3. <strong>Aluminum Casing Profiles</strong>: These encase the insulation, providing a finished look and additional protection. 4. <strong>Aluminum Angle Profiles</strong>: Used for corners and edges to maintain structural integrity. 5. <strong>Aluminum Trim Profiles</strong>: For finishing touches and to cover gaps or seams. Each type serves a specific function in the insulation system, ensuring energy efficiency and a durable exterior wall construction.</p>

Send your message to us

Led Strip Channels Aluminum Profiles for Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords