LED Aluminum Profiles for Coated Aluminum Round Tubes in Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

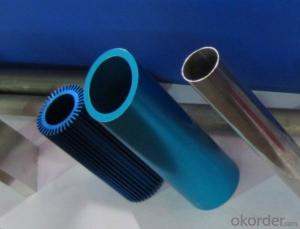

Name:aluminum tube&aluminum pipe

Material | 1000series,2000series,3000series.... |

Temper | T4,T5,T6 |

ISO Certificate | ISO9001:2008,SGS |

Size | The size are available in accordance with customers' options. |

Mill finish, Powder Coating, Anodizing, Sandblasting Anodizing, | |

Surface Processing | Cataphoresis, Sandblasting Cataphoresis, Wooden Print etc. |

Shape | round pipe |

Use | Building,Machine,Decoration,etc |

Color | Silver,Golden,Black,Red,Blue a,etc |

Packing: | Export sea worthy package |

Delivery: | Within 30 days after receiving 30%T/T of deposit or L/C |

MOQ: | 1 Metric Ton/Metric Tons |

Price terms: | FOB, CFR, CIF |

Payment terms: | T/T, L/C |

Application | aluminum pipe applies to Structural use ,roofing, commercial use, household appliance, industry, family etc |

Quality control: | a)Mill Test Certificate is supplied with shipment. b)Third party inspection is highly welcomed. |

- Q: Are aluminum profiles painted by powder or by fluorocarbon spray? How can they be distinguished from appearance?

- The biggest weakness of powder spraying is that it is afraid of the ultraviolet radiation of the sun. The long-term radiation will cause the natural fading. The face of the aluminum plate and the non bright face are obviously different in color after a few years, and the color difference is obvious for 2-5 years. Now appearing on the market name of color for aluminum, aluminum doors and windows, is to use ordinary aluminum powder coating and. Aluminum doors and windows to increase color varieties, but also to enhance corrosion resistance. Another kind of electrostatic spraying liquid spraying, also called fluorocarbon spraying called curium oil, Hongkong. Belonging to high-grade spraying, higher prices, has long been applied in foreign countries. In the past two years, it has been widely used in aluminum curtain wall. Because of its excellent characteristics, more and more attention has been paid to the construction industry and users. Fluorocarbon coating has excellent anti fade, anti frost, anti air pollution (acid rain) corrosion, anti UV ability, strong crack resistance and can withstand harsh weather conditions. Is less than general paint

- Q: Can aluminum profiles be used in transportation and logistics applications?

- Yes, aluminum profiles can be used in transportation and logistics applications. Aluminum is a lightweight and durable material that is commonly used in the manufacturing of transportation vehicles such as cars, trucks, trains, and airplanes. It is also used in the construction of storage and shipping containers, racks, and shelving systems in logistics applications.

- Q: Can aluminum profiles be used in signage or display applications?

- Yes, aluminum profiles can be used in signage or display applications. Aluminum profiles are lightweight, durable, and versatile, making them suitable for various applications such as sign frames, display stands, and exhibition booths. Additionally, aluminum profiles can be easily customized and offer a sleek and modern appearance, making them a popular choice in the signage and display industry.

- Q: What is the difference between the type 4040c and 4040d of aluminum profile?

- I think you see two things and find it makes no difference to ask the question! If so, the two profiles are identical, just numbers from different companies!

- Q: What does aluminum 6063 T5 mean?

- 6063 is a kind of 6 alloy, T5 is quenched, air-cooled

- Q: This question asks for a method to determine the quantity of aluminum profiles required for a construction project.

- <p>To calculate the amount of aluminum profiles needed for a building project, follow these steps: 1. Determine the design specifications and dimensions of the project, including the length, width, and height of the structure. 2. Identify the types and sizes of aluminum profiles required based on the structural needs and design. 3. Calculate the total linear footage of each profile type needed by multiplying the length of each required section by the number of sections. 4. Add up the total linear footage for all profile types. 5. Account for waste and cutting losses, typically adding 5-10% to the total. 6. Ensure the calculations comply with building codes and safety standards. Consult with engineers or architects if necessary.</p>

- Q: This question asks for a list of different types of fasteners that are typically used in conjunction with aluminum extrusions.

- <p>Common types of fasteners used with aluminum extrusions include: 1. T-nuts and T-bolts, which provide a secure way to mount components to the extrusion. 2. Clamps and brackets, which can be used to hold items in place without drilling. 3. Corner brackets, which are used to connect two extrusions at right angles. 4. End caps, which protect the ends of the extrusion and can also serve as a mounting point. 5. Dowel pins, which are used to align and secure extrusions together. 6. Spacers, which maintain a consistent distance between extrusions. 7. Adhesives, which can be used for bonding parts to the extrusion. 8. Rivets, which provide a permanent connection between extrusions and other materials. These fasteners are chosen based on the specific application, load requirements, and design considerations.</p>

- Q: What are the specific needs or standards for utilizing aluminum profiles in cold weather conditions?

- <p>In cold climates, aluminum profiles must meet certain requirements to ensure durability and functionality. These include resistance to extreme temperatures, which may affect the material's strength and flexibility. Profiles should be made from high-quality aluminum alloys designed for low-temperature performance. Additionally, proper thermal breaks may be necessary to prevent heat loss through the profile. Corrosion resistance is also crucial, as cold environments can accelerate the process. Lastly, it's essential to consider the expansion and contraction of aluminum in cold temperatures, ensuring the design accommodates these changes to prevent warping or cracking.</p>

- Q: Are there any fire safety considerations when using aluminum profiles?

- Fire safety considerations must be taken into account when utilizing aluminum profiles. Although aluminum is not combustible, it can still contribute to the spread and intensity of a fire. Aluminum profiles, particularly in construction or industrial settings, can act as fuel for a fire and potentially worsen its severity. One crucial consideration is the fire rating of the aluminum profiles. Fire ratings indicate how long a material can withstand fire exposure before failing. It is vital to choose aluminum profiles with appropriate fire ratings that match the specific application requirements. This guarantees that the profiles can delay the fire's spread, providing valuable time for evacuation and firefighting efforts. Another consideration is the use of suitable insulation materials. Aluminum profiles are often used in building facades, curtain walls, and other structural applications. In these cases, it is important to ensure that the insulation materials used with the aluminum profiles are fire-resistant. This prevents the fire from spreading through the building envelope and reduces the risk of structural failure. Furthermore, fire safety measures should be implemented during installation. Proper firestopping techniques should be applied to seal any gaps or penetrations around the aluminum profiles. This prevents flames, smoke, and hot gases from passing from one compartment to another, limiting the fire's spread. Regular maintenance and inspection of the aluminum profiles are also crucial for fire safety. Any damage or deterioration should be promptly addressed to prevent potential fire hazards. Additionally, adequate fire detection and suppression systems should be in place to detect and control fires in a timely manner. Overall, although aluminum profiles themselves are not combustible, it is imperative to consider various fire safety measures when using them in construction or industrial applications. By selecting suitable fire-rated profiles, using fire-resistant insulation materials, employing proper installation techniques, and conducting regular inspections, the risk of fire can be minimized, ensuring the safety of occupants and property.

- Q: Can aluminum profiles be used in the production of medical devices?

- Medical devices can utilize aluminum profiles because of their lightweight and corrosion-resistant nature. This material provides numerous benefits for medical applications. It can be easily manipulated through machining, forming, and welding to create intricate and accurate components required in medical devices. Furthermore, aluminum profiles possess exceptional conductivity properties, which are crucial for devices that rely on electrical connections. In addition to these advantages, aluminum is non-toxic, non-magnetic, and does not emit harmful substances, ensuring its safety in medical settings. Consequently, it is extensively employed in the production of various medical devices, including surgical instruments, hospital bed frames, wheelchair components, IV stands, and more.

Send your message to us

LED Aluminum Profiles for Coated Aluminum Round Tubes in Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords