Latest FRP Pultrusion Profiles for Anti-Corrosion and Anti-Rust Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

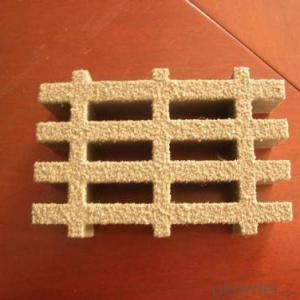

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

SPECIFICATION

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: Can FRP pultrusion profiles be used in the renewable energy and solar power industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the renewable energy and solar power industry. FRP pultrusion profiles possess several key characteristics that make them ideal for such applications. Firstly, FRP pultrusion profiles have high strength-to-weight ratio, meaning they are lightweight yet strong, which is crucial in the renewable energy sector where materials need to withstand various environmental conditions while being cost-effective. Secondly, FRP pultrusion profiles offer excellent corrosion resistance, ensuring durability and longevity in outdoor and potentially corrosive environments, such as solar power plants or wind farms. Additionally, these profiles have excellent electrical insulation properties, making them suitable for electrical applications commonly found in the renewable energy industry. Moreover, FRP pultrusion profiles can be easily customized into various shapes and sizes, enabling the design and engineering of complex structures required for solar power installations or wind turbine blades. Furthermore, FRP materials are non-conductive and non-magnetic, making them safe for use in electrical and magnetic fields associated with renewable energy systems. Overall, FRP pultrusion profiles offer a combination of strength, durability, lightweight, corrosion resistance, and electrical insulation properties that make them highly suitable for use in the renewable energy and solar power industry.

- Q: Are FRP pultrusion profiles resistant to chemicals used in semiconductor manufacturing?

- FRP pultrusion profiles have a general resistance to chemicals typically employed in semiconductor manufacturing. Known for its exceptional chemical resistance, FRP is a suitable material for various industrial applications, including the semiconductor industry. The composite structure of FRP, which comprises a reinforced fiber matrix embedded in a polymer resin, provides resistance to a broad range of chemicals such as acids, alkalis, solvents, and other aggressive substances commonly used in semiconductor manufacturing processes. This resistance guarantees that FRP pultrusion profiles can endure exposure to these chemicals without significant degradation or corrosion, making them a dependable choice for implementation in semiconductor manufacturing environments. However, it is always advisable to refer to the manufacturer's specific chemical resistance data to ensure compatibility with the particular chemicals and concentrations employed in a specific semiconductor manufacturing process.

- Q: How do FRP pultrusion profiles compare to fiberglass reinforced panels (FRP)?

- FRP pultrusion profiles and fiberglass reinforced panels (FRP) are both commonly used materials in various industries due to their high strength and durability. However, there are some notable differences when comparing these two FRP products. 1. Manufacturing Process: FRP pultrusion profiles are created through a continuous pultrusion process, where fibers are pulled through a resin bath and then cured using heat or ultraviolet light. This results in a solid and uniform profile with consistent mechanical properties. On the other hand, fiberglass reinforced panels are made by combining layers of fiberglass mat and resin, which are typically molded or pressed together. This process can sometimes result in variations in thickness and mechanical properties across the panel. 2. Structural Strength: FRP pultrusion profiles are known for their exceptional strength-to-weight ratio. The continuous fiber reinforcement used in pultrusion provides high stiffness and load-bearing capacity, making them suitable for structural applications. Conversely, while fiberglass reinforced panels are also strong, they may not possess the same level of structural integrity as pultrusion profiles due to the potential for variations in resin content and fiber distribution. 3. Design Flexibility: FRP pultrusion profiles offer greater design flexibility compared to fiberglass reinforced panels. The pultrusion process allows for the incorporation of various shapes and configurations, such as I-beams, angles, tubes, and custom profiles. This versatility enables engineers to tailor the profiles to specific project requirements. In contrast, fiberglass reinforced panels are typically limited to flat or slightly curved surfaces and do not provide the same level of customization. 4. Surface Finish: FRP pultrusion profiles often have a smooth and consistent surface finish due to the pultrusion process. This makes them more aesthetically appealing and suitable for applications where appearance is important. Fiberglass reinforced panels, on the other hand, may have a textured or uneven surface, which can impact their visual appeal in certain applications. 5. Cost: When comparing costs, FRP pultrusion profiles are generally more expensive than fiberglass reinforced panels. The pultrusion process requires specialized equipment and has higher manufacturing costs. Fiberglass reinforced panels, on the other hand, have lower production costs due to their simpler manufacturing process. However, it is important to consider the specific application requirements and long-term performance when evaluating the cost-effectiveness of these materials. In summary, FRP pultrusion profiles and fiberglass reinforced panels have their own unique characteristics and advantages. The choice between the two will depend on factors such as structural requirements, design flexibility, surface finish, and cost considerations.

- Q: Can FRP pultrusion profiles be customized or tailored to specific project requirements?

- Indeed, FRP (Fiber Reinforced Polymer) pultrusion profiles have the capability to be customized or tailored according to the specific demands of a project. The process of pultrusion, which is employed in the manufacturing, enables the creation of continuous fiber-reinforced composite profiles while providing a considerable amount of design flexibility. By adjusting the design and manufacturing parameters, the dimensions, shapes, and mechanical properties required by a project can be accommodated. The customization procedure commences with a comprehension of the project's needs and specifications. This involves identifying the desired profile dimensions, cross-sectional shape, and mechanical properties such as strength, stiffness, and durability. Based on these requirements, engineers and manufacturers can devise a personalized solution. The customization of FRP pultrusion profiles can be accomplished through various methods. Firstly, the selection of reinforcement materials, such as fiberglass, carbon fiber, or aramid fiber, can be made based on the desired mechanical characteristics. The orientation and volume fraction of the fibers can also be adjusted to optimize the strength and stiffness of the profile. Additionally, the resin matrix utilized in the pultrusion process can be customized to enhance specific properties like fire resistance, chemical resistance, or UV resistance. To meet the project's requirements, different resin systems including polyester, vinyl ester, or epoxy can be utilized. Furthermore, during the manufacturing process, the pultrusion method allows for the incorporation of additional features. This includes the addition of inserts, fastener holes, grooves, or other structural details to the profile. These modifications can be tailored to the specific project requirements, ensuring compatibility with the overall design and assembly. In conclusion, FRP pultrusion profiles offer a significant level of customization and tailoring to cater to the specific demands of a project. This versatility has made them a favored choice in various industries such as construction, infrastructure, aerospace, and automotive, where lightweight, durable, and corrosion-resistant materials are essential.

- Q: How do FRP pultrusion profiles perform in high-humidity environments?

- FRP pultrusion profiles perform exceptionally well in high-humidity environments. The inherent properties of fiberglass reinforced plastic, such as corrosion resistance and moisture resistance, make these profiles highly durable and resistant to degradation caused by exposure to moisture and humidity. Additionally, FRP pultrusion profiles do not rot, warp, or rust, making them an ideal choice for applications in high-humidity environments.

- Q: Are FRP pultrusion profiles resistant to chemicals used in mining operations?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemicals commonly used in mining operations. The composite material used in FRP pultrusion profiles is inherently corrosion-resistant and can withstand the harsh chemical environment typically encountered in mining. Additionally, FRP pultrusion profiles offer excellent resistance to acids, alkalis, solvents, and other chemicals, making them a durable and reliable choice for mining applications.

- Q: Are pultruded FRP sections strong? What are its main areas of application?

- More fields. Advantage is obvious, if the corrosion resistance, insulation resistance, quality is lighter than steel; strength and steel strength comparable;

- Q: Are FRP pultrusion profiles non-conductive?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are non-conductive. This is because they are made up of a combination of reinforced fibers, typically fiberglass, and a polymer resin matrix. The fiberglass fibers provide the strength and stiffness, while the polymer resin acts as a binder to hold the fibers together. One of the key advantages of FRP pultrusion profiles is their excellent electrical insulation properties. Unlike metals, which are conductive, FRP profiles do not conduct electricity. This makes them ideal for applications where electrical insulation is required. In addition to being non-conductive, FRP pultrusion profiles also offer other benefits such as corrosion resistance, high strength-to-weight ratio, and low maintenance requirements. These properties make them suitable for a wide range of applications, including electrical and telecom infrastructure, chemical processing plants, bridges, and building construction. It is important to note that the non-conductive nature of FRP pultrusion profiles does not mean they cannot be made conductive if required. Special additives or coatings can be incorporated during the manufacturing process to impart conductive properties if needed.

- Q: Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in wastewater treatment facilities. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, which make them suitable for use in harsh environments like wastewater treatment facilities. In wastewater treatment facilities, there are various applications where FRP pultrusion profiles can be used. These include but are not limited to walkways, handrails, ladders, grating, and structural supports. The corrosion resistance of FRP makes it ideal for use in areas exposed to moisture and chemicals present in wastewater. Furthermore, FRP profiles are lightweight, which simplifies installation and reduces the load on supporting structures. The durability of FRP pultrusion profiles ensures long-term performance, even in aggressive environments. They have a high resistance to chemical attack, UV radiation, and bacterial growth, making them suitable for wastewater treatment applications. Additionally, FRP profiles can be designed to meet specific load requirements and can be easily fabricated to fit various shapes and sizes. Moreover, FRP pultrusion profiles offer excellent electrical insulation properties, which can be advantageous in wastewater treatment facilities where electrical safety is a concern. In summary, FRP pultrusion profiles can be effectively used in wastewater treatment facilities due to their corrosion resistance, durability, lightweight nature, and versatility in design and fabrication. These profiles can provide long-lasting solutions for various applications within these facilities, ensuring operational efficiency and minimizing maintenance requirements.

- Q: Can FRP pultrusion profiles be used in walkway systems?

- Yes, FRP pultrusion profiles can be used in walkway systems. FRP pultrusion profiles are lightweight, strong, and resistant to corrosion, making them suitable for use in various applications, including walkways. They offer durability, low maintenance, and can withstand heavy loads, making them a reliable choice for walkway systems.

Send your message to us

Latest FRP Pultrusion Profiles for Anti-Corrosion and Anti-Rust Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords