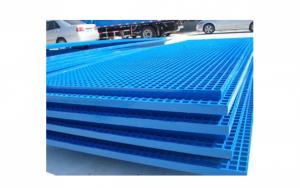

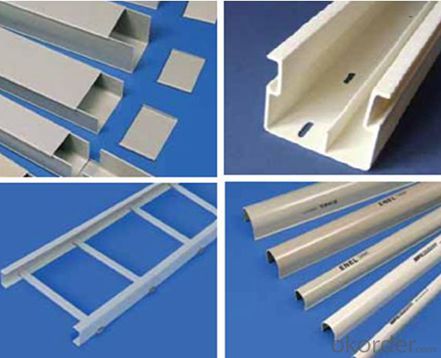

FRP Pultrusion Profiles - Pultruded Grating with High Resistance to Weathering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

FRP PULTRUDED GRATING AND PULTRUSION PROCESS

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

COMPANT DESCRIPTION

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: How do FRP pultrusion profiles handle cyclic loading?

- FRP pultrusion profiles are known for their excellent performance under cyclic loading conditions. The unique combination of materials and manufacturing process used in pultrusion makes these profiles highly resistant to fatigue and cyclic loading effects. One key factor that contributes to the superior performance of FRP pultrusion profiles under cyclic loading is their inherent high strength-to-weight ratio. These profiles are made using continuous fibers, typically fiberglass, which are impregnated with a resin matrix. This results in a lightweight yet strong material that can handle repeated loading without experiencing significant degradation or fatigue. Additionally, the pultrusion process allows for precise control over the fiber orientation and resin distribution within the profile. This results in a uniform and consistent material composition throughout the entire length of the profile. As a result, FRP pultrusion profiles exhibit excellent load distribution characteristics, minimizing stress concentrations and preventing localized failure under cyclic loading conditions. Furthermore, the corrosion resistance of FRP pultrusion profiles plays a crucial role in their ability to handle cyclic loading. Unlike traditional materials such as steel, FRP profiles do not suffer from corrosion-related issues, such as rust or pitting. This corrosion resistance ensures that the profiles maintain their structural integrity even when subjected to cyclic loading over extended periods of time. Overall, FRP pultrusion profiles are specifically designed and manufactured to withstand cyclic loading conditions. Their high strength-to-weight ratio, uniform material composition, and corrosion resistance make them ideal for applications where cyclic loading is a significant factor. Whether it's in structural reinforcements, bridges, sporting equipment, or various industrial applications, FRP pultrusion profiles have proven to be reliable and durable under cyclic loading.

- Q: Are FRP pultrusion profiles resistant to alkalis?

- Yes, FRP pultrusion profiles are generally resistant to alkalis.

- Q: Can FRP pultrusion profiles be used in the construction of wind turbine blades?

- Indeed, FRP pultrusion profiles have the capability to be utilized in the construction of wind turbine blades. There are several advantages offered by FRP pultrusion profiles that render them suitable for this purpose. To begin with, FRP pultrusion profiles possess a lightweight yet robust nature, a crucial characteristic for wind turbine blades since they must endure the aerodynamic forces exerted by the wind. The high strength-to-weight ratio of FRP pultrusion profiles permits the creation of longer and more effective blades. Moreover, FRP pultrusion profiles exhibit exceptional corrosion resistance properties, a vital attribute for wind turbines that are exposed to harsh weather conditions. In contrast to traditional materials like steel, FRP does not corrode, thereby ensuring an extended service life for the wind turbine blades. Additionally, FRP pultrusion profiles are customizable to satisfy specific design requirements. This flexibility allows for the optimization of blade performance by tailoring the shape, thickness, and stiffness of the profiles to maximize energy capture and minimize fatigue. Furthermore, FRP pultrusion profiles possess good fatigue resistance, enabling them to endure repeated loading cycles without experiencing significant performance degradation. This is particularly crucial for wind turbine blades, which encounter cyclic loading due to wind gusts and changes in wind direction. Lastly, FRP pultrusion profiles are electrically non-conductive, a beneficial trait for wind turbine blades as it eliminates the risk of electrical discharge during operation. In conclusion, the lightweight, strong, corrosion-resistant, and customizable nature of FRP pultrusion profiles makes them an outstanding choice for the construction of wind turbine blades. This contributes to the advancement of more efficient and durable wind energy systems.

- Q: Can FRP pultrusion profiles be used in the water and wastewater treatment industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the water and wastewater treatment industry. FRP pultrusion profiles are highly durable, corrosion-resistant, and have excellent mechanical properties, making them suitable for various applications in the water and wastewater treatment industry. One of the main advantages of FRP pultrusion profiles is their resistance to corrosion. Water and wastewater treatment facilities often deal with aggressive chemicals, high humidity, and corrosive environments. Traditional materials like steel or wood may deteriorate and require frequent maintenance or replacement. However, FRP pultrusion profiles are specifically designed to withstand harsh conditions without corrosion, ensuring long-term performance and reducing maintenance costs. Additionally, FRP pultrusion profiles offer excellent strength-to-weight ratio, making them ideal for structural applications in water and wastewater treatment facilities. They can be used as walkways, handrails, grating, ladders, and other structural components. The lightweight nature of FRP profiles allows for easy installation and minimizes the load on the supporting structures. Furthermore, FRP pultrusion profiles are non-conductive, providing an added safety benefit in water and wastewater treatment facilities. This property is particularly important when dealing with electrical equipment or applications near water sources, reducing the risk of electrical hazards. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, including different shapes, sizes, and colors. This flexibility allows for greater design freedom, ensuring that the profiles can be tailored to fit the specific needs of water and wastewater treatment projects. Overall, the use of FRP pultrusion profiles in the water and wastewater treatment industry offers numerous advantages, including corrosion resistance, high strength, lightweight, non-conductivity, and design flexibility. These qualities make FRP profiles a reliable and cost-effective choice for various applications in this industry.

- Q: The difference between polyurethane pultruded profiles and glass reinforced plastic profiles

- Compared with other materials, pultrusion with polyurethane can produce a variety of benefits. The utility model can improve the content of the glass fiber in the product and greatly improve the strength of the product. For example, pultruded window frames made of glass fiber and polyurethane resin, the strength of the resulting window frames is 8 times higher than that of the PVC window frames, and the conductivity is 40 times lower than that of aluminum. Therefore, the insulation performance is much better.

- Q: Can FRP pultrusion profiles be used in high-voltage applications?

- FRP pultrusion profiles are suitable for use in high-voltage applications due to their highly durable and electrically insulating nature. The material's consistency and uniform composition achieved through the pultrusion process ensure excellent electrical insulation properties. These profiles possess a high dielectric strength, enabling them to withstand high voltages without electrical breakdown. Additionally, they exhibit low electrical conductivity, preventing the flow of electric current. As a result, FRP profiles are ideal for applications requiring crucial electrical insulation, such as high-voltage power transmission and distribution systems, electrical substations, and equipment insulation. Aside from their electrical insulation capabilities, FRP pultrusion profiles offer numerous advantages in high-voltage applications. They are lightweight, corrosion resistant, and have a high strength-to-weight ratio, facilitating easy handling, installation, and maintenance. Furthermore, FRP profiles are non-magnetic and non-conductive, minimizing the risk of electromagnetic interference (EMI) in sensitive electrical systems. In conclusion, FRP pultrusion profiles are a dependable and efficient choice for high-voltage applications, providing exceptional electrical insulation, durability, and performance in challenging environments.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical packaging?

- Yes, FRP pultrusion profiles are highly resistant to chemicals used in pharmaceutical packaging. The unique properties of fiberglass reinforced plastic, such as its corrosion resistance and non-reactivity to most chemicals, make FRP pultrusion profiles an ideal choice for pharmaceutical packaging applications.

- Q: Are FRP pultrusion profiles resistant to alkaline substances?

- Yes, FRP pultrusion profiles are generally resistant to alkaline substances. The composition and manufacturing process of FRP pultrusion profiles make them highly resistant to corrosion and damage caused by alkaline substances.

- Q: Are FRP pultrusion profiles resistant to nitric acid?

- FRP pultrusion profiles are generally resistant to nitric acid. Nitric acid is a strong oxidizing agent and can corrode many materials including metals. However, FRP (Fiber Reinforced Polymer) pultrusion profiles are made of composite materials that are specifically designed to be resistant to various corrosive substances, including nitric acid. The corrosion resistance of FRP pultrusion profiles can be attributed to the combination of their reinforcing fibers, such as fiberglass or carbon fiber, and the resin matrix that binds these fibers together. The resin matrix used in FRP profiles is typically a thermosetting polymer, such as polyester or epoxy, which provides a protective barrier against corrosive substances. Nitric acid is known to attack metals, causing corrosion and degradation. However, FRP pultrusion profiles offer excellent resistance to nitric acid due to the inert nature of the composite materials used. The reinforcing fibers in FRP profiles do not react with nitric acid, and the resin matrix acts as a barrier, preventing the acid from reaching and corroding the fibers. It is important to note that the specific resistance of FRP pultrusion profiles to nitric acid may vary depending on the specific composition of the composite materials used and the concentration and temperature of the nitric acid. Therefore, it is always recommended to consult with the manufacturer or supplier of FRP profiles to ensure their compatibility with nitric acid in specific applications.

- Q: Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Indeed, FRP pultrusion profiles have the capability to be utilized in wastewater treatment facilities. These profiles possess numerous benefits, including a high strength-to-weight ratio, resistance to corrosion, and durability, all of which make them highly suitable for the challenging conditions found in such facilities. In wastewater treatment facilities, there exists a wide range of applications where FRP pultrusion profiles can be effectively employed. These applications encompass walkways, handrails, ladders, grating, and structural supports, among others. The corrosion resistance of FRP makes it particularly well-suited for deployment in areas that are exposed to moisture and the chemicals present in wastewater. Furthermore, the lightweight nature of FRP profiles simplifies the installation process and reduces the burden placed on supporting structures. The durability of FRP pultrusion profiles guarantees long-term performance, even in aggressive environments. They exhibit a remarkable resistance to chemical attacks, UV radiation, and bacterial growth, rendering them highly appropriate for wastewater treatment applications. Additionally, FRP profiles can be tailored to meet specific load requirements and can be easily fabricated to accommodate various shapes and sizes. Furthermore, FRP pultrusion profiles possess outstanding electrical insulation properties, which can prove advantageous in wastewater treatment facilities where electrical safety is of utmost concern. To summarize, FRP pultrusion profiles can be effectively employed in wastewater treatment facilities due to their corrosion resistance, durability, lightweight nature, and versatility in terms of design and fabrication. These profiles provide long-lasting solutions for a variety of applications within these facilities, ensuring operational efficiency and minimizing maintenance needs.

Send your message to us

FRP Pultrusion Profiles - Pultruded Grating with High Resistance to Weathering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords