FRP Pultrusion Profiles:Anti-Corrosion and Anti-Rust FRP Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

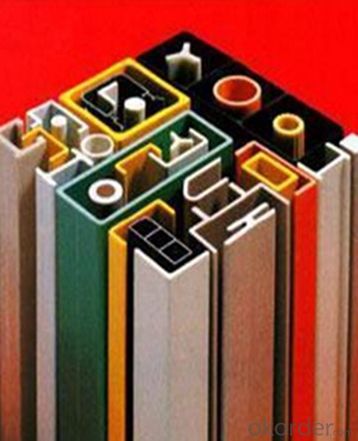

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

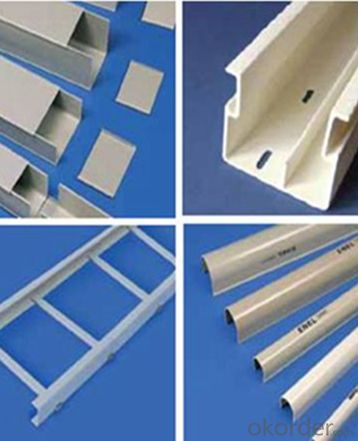

PICTURES

- Q: Can FRP pultrusion profiles be used in high-voltage applications?

- FRP pultrusion profiles are suitable for use in high-voltage applications due to their highly durable and electrically insulating nature. The material's consistency and uniform composition achieved through the pultrusion process ensure excellent electrical insulation properties. These profiles possess a high dielectric strength, enabling them to withstand high voltages without electrical breakdown. Additionally, they exhibit low electrical conductivity, preventing the flow of electric current. As a result, FRP profiles are ideal for applications requiring crucial electrical insulation, such as high-voltage power transmission and distribution systems, electrical substations, and equipment insulation. Aside from their electrical insulation capabilities, FRP pultrusion profiles offer numerous advantages in high-voltage applications. They are lightweight, corrosion resistant, and have a high strength-to-weight ratio, facilitating easy handling, installation, and maintenance. Furthermore, FRP profiles are non-magnetic and non-conductive, minimizing the risk of electromagnetic interference (EMI) in sensitive electrical systems. In conclusion, FRP pultrusion profiles are a dependable and efficient choice for high-voltage applications, providing exceptional electrical insulation, durability, and performance in challenging environments.

- Q: Can FRP pultrusion profiles be used in mining applications?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in mining applications. FRP pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them well-suited for various mining applications. In mining operations, FRP pultrusion profiles can be used for a range of purposes. They can be used for structural support in underground mines, such as in the construction of tunnels, shafts, and mine roofs. Their high strength allows them to withstand heavy loads and provide long-term support. FRP pultrusion profiles can also be used for equipment and machinery support, such as in conveyor systems, pumps, and tanks. Their resistance to corrosion makes them suitable for use in harsh mining environments, where exposure to moisture, chemicals, and abrasive materials is common. Furthermore, FRP pultrusion profiles can be used for safety applications in mining, including handrails, walkways, and grating systems. These profiles can provide reliable and non-slip surfaces, ensuring the safety of workers in mining operations. Overall, FRP pultrusion profiles offer several advantages in mining applications, including their high strength, corrosion resistance, durability, and ease of installation. These qualities make them a viable and cost-effective choice for various mining operations, contributing to improved efficiency and safety in the industry.

- Q: Can FRP pultrusion profiles be used in electrical or telecommunications applications?

- Yes, FRP pultrusion profiles can be used in electrical or telecommunications applications. FRP (Fiber Reinforced Polymer) pultrusion profiles have excellent electrical insulation properties and are resistant to corrosion, making them suitable for use in electrical and telecommunications infrastructure. Additionally, their light weight, high strength, and design flexibility make them a desirable choice for applications such as cable trays, support structures, and enclosures in these industries.

- Q: What is the dimensional stability of FRP pultrusion profiles?

- The dimensional stability of FRP (Fiber Reinforced Polymer) pultrusion profiles is generally very high. This is due to the unique structural characteristics of FRP materials and the pultrusion manufacturing process. FRP pultrusion profiles are made by pulling continuous fibers, such as glass or carbon, through a resin bath and then through a heated die. The resin is typically a thermosetting polymer, which means it undergoes a chemical reaction during the curing process to become a rigid and durable material. The pultrusion process ensures that the fibers are evenly distributed and aligned within the profile, resulting in a highly uniform and consistent material. This uniformity contributes to the dimensional stability of FRP pultrusion profiles. Furthermore, the thermosetting nature of the resin matrix provides excellent dimensional stability. Once the resin is cured, it retains its shape and dimensions even under varying temperature and humidity conditions. This makes FRP pultrusion profiles resistant to warping, shrinking, or expanding, which can occur in other materials like wood or metals. The high dimensional stability of FRP pultrusion profiles makes them ideal for a wide range of applications where precise and consistent dimensions are required. These profiles are commonly used in industries such as construction, infrastructure, transportation, and marine, where their ability to maintain their shape and dimensions over time is crucial for long-term performance and structural integrity.

- Q: Can FRP pultrusion profiles be used in renewable energy projects?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can certainly be used in renewable energy projects. FRP pultrusion profiles offer a wide range of advantages that make them suitable for various applications within the renewable energy sector. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for use in wind turbine blades. The lightweight nature of FRP materials allows for increased efficiency in wind energy generation by reducing the load on the turbine, thus improving overall performance. Additionally, the high strength-to-weight ratio of FRP profiles ensures durability and longevity, even in harsh environmental conditions. Secondly, FRP pultrusion profiles exhibit excellent corrosion resistance, making them suitable for solar panel mounting structures and other components exposed to moisture and outdoor elements. This corrosion resistance ensures that FRP profiles maintain their structural integrity and performance over an extended period of time, reducing the need for frequent maintenance and replacement. Thirdly, FRP pultrusion profiles can be customized to meet specific project requirements, allowing for flexibility in design and functionality. They can be easily molded into complex shapes and sizes, enabling the creation of innovative and efficient solutions for renewable energy projects. Moreover, FRP materials are non-conductive and have excellent electrical insulation properties, making them suitable for use in electrical enclosures and support structures for renewable energy systems such as solar power plants. In conclusion, FRP pultrusion profiles can be effectively utilized in renewable energy projects due to their lightweight, strong, corrosion-resistant, customizable, and electrically-insulating properties. These characteristics make FRP profiles a reliable and sustainable choice for various applications within the renewable energy sector.

- Q: What raw materials do FRP pultrusion require?

- Resin: commonly used unsaturated polyester resin, epoxy resin, vinyl ester resin, phenolic resin;

- Q: Are FRP pultrusion profiles resistant to oil and grease?

- Yes, FRP pultrusion profiles are highly resistant to oil and grease due to the inherent properties of the fiberglass reinforcement used in their construction. The composite material offers excellent chemical resistance, making it suitable for applications where exposure to oil and grease is expected.

- Q: FRP pultrusion process?

- Pultrusion is a process for the production of glass steel linear profiles, its raw materials are used in unsaturated polyester resin and continuous glass fiber roving and mat, high performance composite materials for all sectors of the use of its production.

- Q: Can FRP pultrusion profiles be used in mining applications?

- Mining applications can utilize FRP pultrusion profiles, which are known for their high strength-to-weight ratio, durability, and corrosion resistance. These profiles are suitable for a range of purposes in mining operations. They can provide structural support in underground mines, including the construction of tunnels, shafts, and mine roofs. Their strength allows them to handle heavy loads and provide long-term support. Additionally, FRP pultrusion profiles can support equipment and machinery like conveyor systems, pumps, and tanks. Their corrosion resistance makes them ideal for use in harsh mining environments that involve exposure to moisture, chemicals, and abrasive materials. Moreover, FRP pultrusion profiles can be used for safety applications in mining, such as handrails, walkways, and grating systems. These profiles offer reliable and non-slip surfaces, ensuring the safety of mining workers. In summary, FRP pultrusion profiles bring several advantages to mining applications, including high strength, corrosion resistance, durability, and easy installation. These qualities make them a cost-effective and viable option for various mining operations, enhancing efficiency and safety in the industry.

- Q: Can FRP pultrusion profiles be used in the construction of shipping containers?

- Yes, FRP pultrusion profiles can be used in the construction of shipping containers. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications including shipping container construction. These profiles can be used for structural components, such as beams, frames, and panels, to enhance the container's strength and longevity. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements and can withstand harsh environmental conditions typically encountered in shipping and transportation.

Send your message to us

FRP Pultrusion Profiles:Anti-Corrosion and Anti-Rust FRP Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords